Building external wall fireproof coating and preparation method

A technology for fire-resistant coatings and buildings, applied in fire-resistant coatings, anti-corrosion coatings, powder coatings, etc., can solve the problems of low tensile strength, general adhesion, and low safety, and achieve excellent alkali resistance, low price, and easy preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

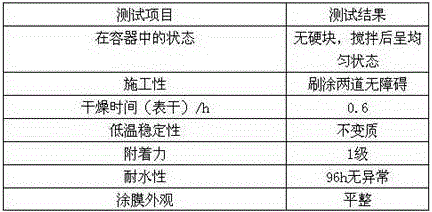

Examples

Embodiment 1

[0035] Example 1 A fireproof coating for exterior walls of buildings, prepared from the following main raw materials in parts by weight (700 g per part): 20.0 parts of amino resin, 1.5 parts of titanium dioxide, 7.8 parts of polycarbonate, magnesium trisilicate 6.4 parts, wollastonite 7.3 parts, Portland cement 3.3 parts, fly ash 5.2 parts, carrageenan 1.2 parts, ethylene glycol 2.4 parts.

[0036] The preparation method of above-mentioned building exterior wall fireproof coating is:

[0037] (1) Take ethylene glycol, add defoamer OS-5201 with 2% ethylene glycol mass, stir evenly, add amino resin, polycarbonate and carrageenan, stir at 600r / min for 30 minutes, set aside;

[0038] (2) Take titanium dioxide, magnesium trisilicate, wollastonite, Portland cement and fly ash, blend them, add the result from step (1), and stir for 10 minutes at a speed of 1400r / min;

[0039] (3) Put the obtained product of step (2) into an extruder to melt and extrude to obtain a molten material. T...

Embodiment 2

[0041] Example 2 A fireproof coating for exterior walls of buildings, prepared from the following main raw materials in parts by weight (700 g per part): 26.0 parts of amino resin, 2.2 parts of titanium dioxide, 10.5 parts of polycarbonate, magnesium trisilicate 8.1 parts, wollastonite 9.4 parts, Portland cement 5.2 parts, fly ash 8.6 parts, carrageenan 1.6 parts, ethylene glycol 3.6 parts.

[0042] The preparation method of above-mentioned building exterior wall fireproof coating is:

[0043] (1) Take ethylene glycol, add defoamer OS-5201 with 5% ethylene glycol mass, stir evenly, add amino resin, polycarbonate and carrageenan, stir at 800r / min for 30 minutes, set aside;

[0044] (2) Take titanium dioxide, magnesium trisilicate, wollastonite, Portland cement and fly ash, blend them, add the result from step (1), and stir at 1800r / min for 10 minutes;

[0045] (3) Put the obtained product of step (2) into the extruder to melt and extrude to obtain the molten material. The temp...

Embodiment 3

[0047] Example 3 A fireproof coating for exterior walls of buildings, prepared from the following main raw materials in parts by weight (each part is 700g): 22.5 parts of amino resin, 1.6 parts of titanium dioxide, 8.4 parts of polycarbonate, magnesium trisilicate 6.7 parts, wollastonite 7.5 parts, Portland cement 3.5 parts, fly ash 5.6 parts, carrageenan 1.3 parts, ethylene glycol 2.6 parts.

[0048] The preparation method of above-mentioned building exterior wall fireproof coating is:

[0049](1) Take ethylene glycol, add defoamer OS-5201 with 2.5% ethylene glycol mass, stir evenly, add amino resin, polycarbonate and carrageenan, stir at 650r / min for 30 minutes, set aside;

[0050] (2) Take titanium dioxide, magnesium trisilicate, wollastonite, Portland cement and fly ash, blend them, add the result from step (1), and stir at 1500r / min for 10 minutes;

[0051] (3) Put the obtained product of step (2) into an extruder to melt and extrude to obtain a molten material. The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com