Cyclone separation type biomass gasifying device

A gasification device and cyclone separation technology, applied in the field of biomass gasification equipment, can solve the problems of large amount of gasification agent and low calorific value of gas production, and achieve the effects of increasing surface area, prolonging residence time, and high-efficiency gas-solid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

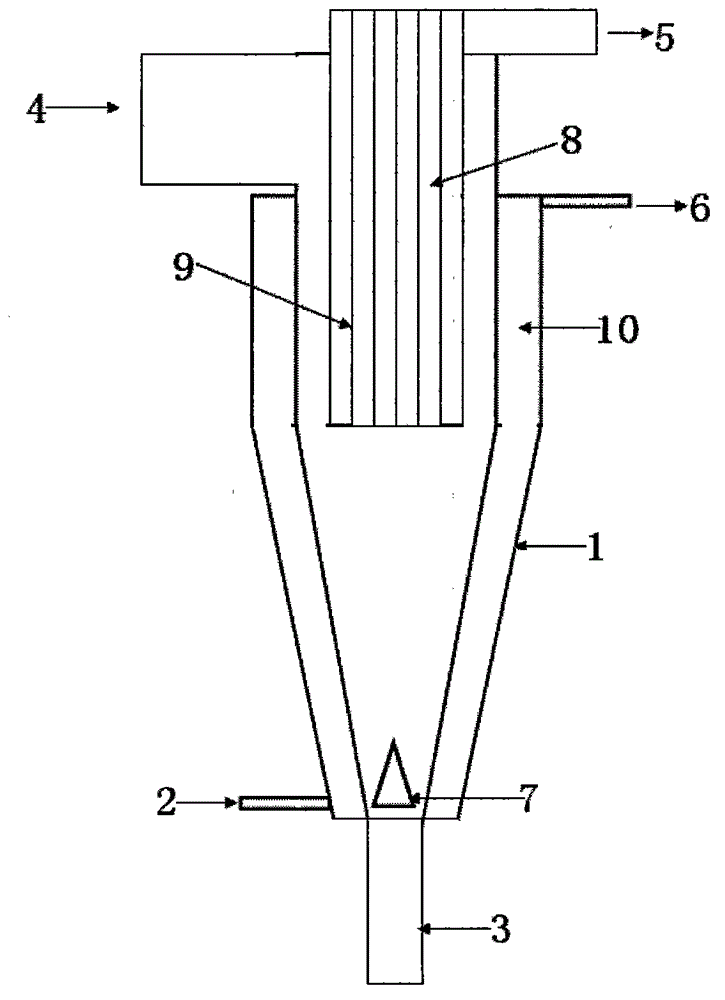

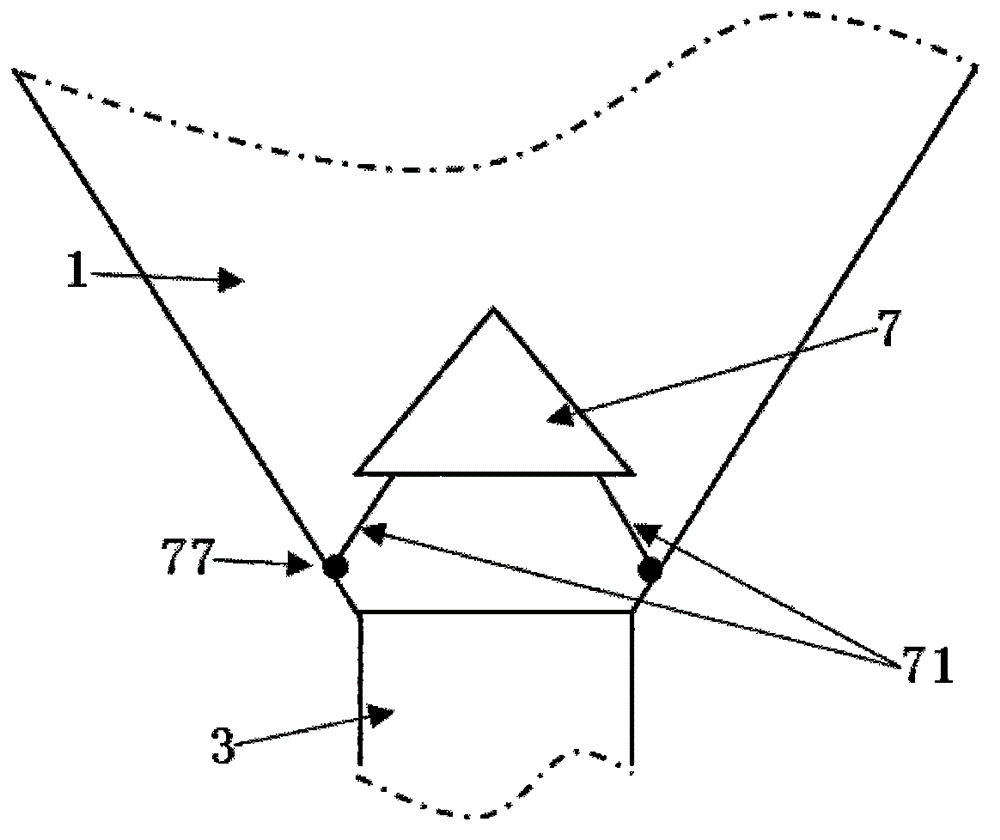

[0027] As shown in the figure, the cyclone-separated biomass gasification device of the present invention has a cylindrical cylinder at the top and a conical cylinder at the bottom, with an inner heating barrier 10 and an outer heat insulation layer. The hot air inlet 2 communicated with the jacket space of the heating compartment 10 and the downward discharge port 3 communicated with the inner space of the reactor main body 1, and the upper end of the reactor main body 1 has biomass communicated with the inner space of the reactor main body 1 The heat carrier and gasification agent inlet 4, the clean combustible gas outlet 5, and the hot gas flow outlet 6 communicated with the jacket space of the heating compartment 10. The inlet 4 for biomass, heat carrier and gasification agent is equipped with a blower; preferably, the cylindrical barrel and the conical barrel are cylindrical barrel and conical barrel respectively. The biomass, heat carrier and gasification agent inlet 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com