A dynamic soft-sensing system and method for silicon content in molten iron during blast furnace ironmaking

A technology for blast furnace ironmaking and blast furnace molten iron, which is applied in blast furnaces, blast furnace details, steel manufacturing processes, etc., can solve the problem of multi-noise, the decline of the generalization ability of the prediction model of silicon content in molten iron, and the inability to capture the inherent dynamic characteristics of the smelting process well And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

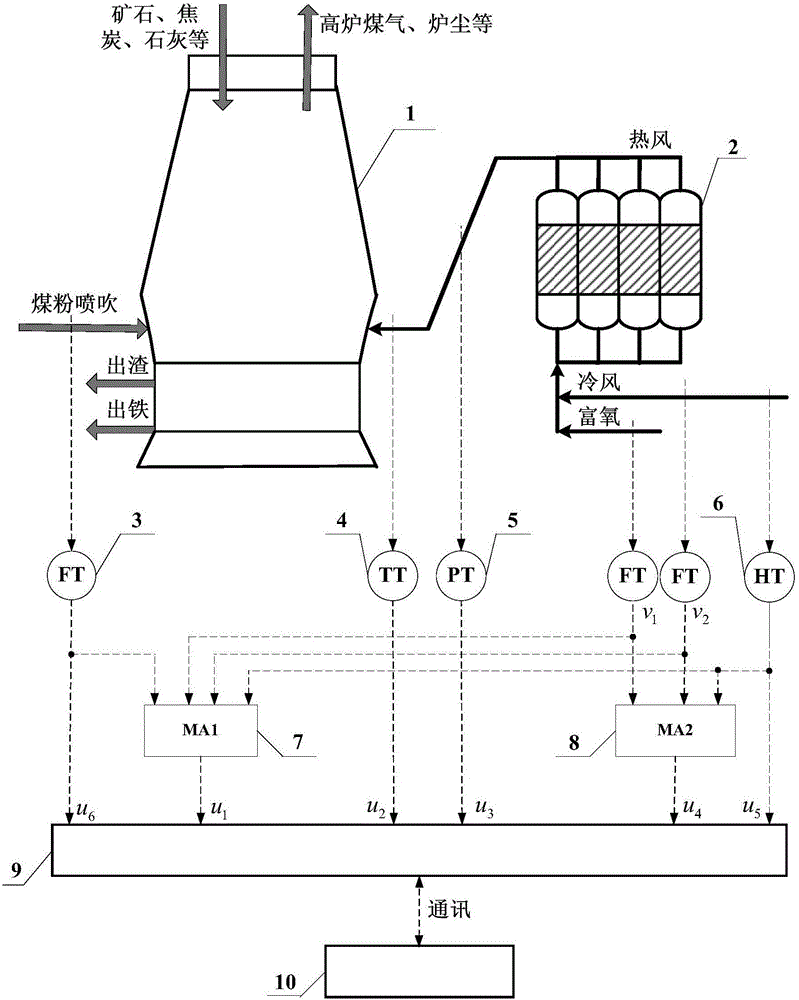

[0052] In this embodiment, the method of implementing the dynamic soft sensing method for the silicon content of molten iron in the blast furnace ironmaking process adopts a measurement system and a computer system 10; figure 1 As shown, the measurement system includes:

[0053] Three flowmeters 3 are used to measure the pulverized coal injection volume, oxygen-enriched flow rate, and cold air flow rate of the pulverized coal injection system of blast furnace 1 respectively;

[0054] A thermometer 4 for online measurement of the hot blast temperature of blast furnace 1 hot blast stove 2;

[0055] A pressure gauge 5 for online measurement of the hot blast pressure of blast furnace 1 hot blast stove 2;

[0056] A hygrometer 6 is used for online measurement of blast humidity of blast furnace 1 hot blast stove 2 .

[0057] In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com