Pre-oriented polyester yarns and preparation method thereof and polyester fiber fabrics and preparation method thereof

A technology of pre-oriented yarn and polyester fiber, which is applied in the field of polyester fiber, can solve the problem of low cross-sectional irregularity of polyester fiber, achieve high degree of irregularity, scientific and reasonable proportioning, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

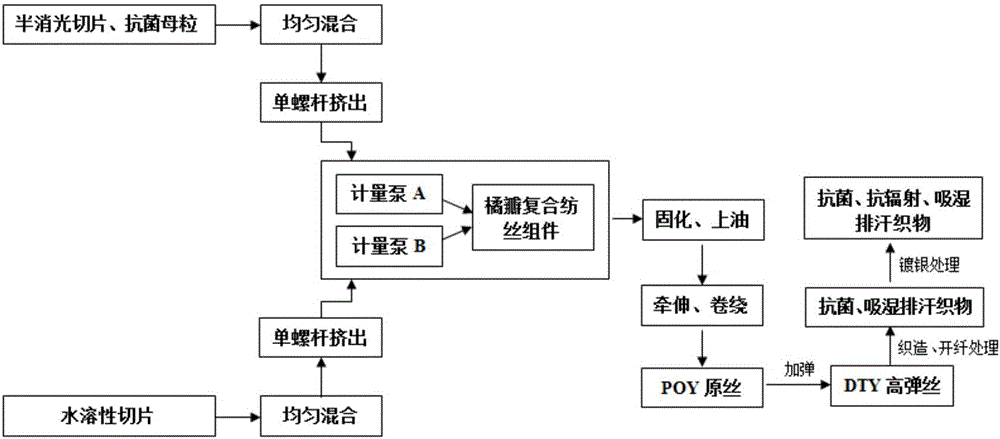

Method used

Image

Examples

Embodiment 1

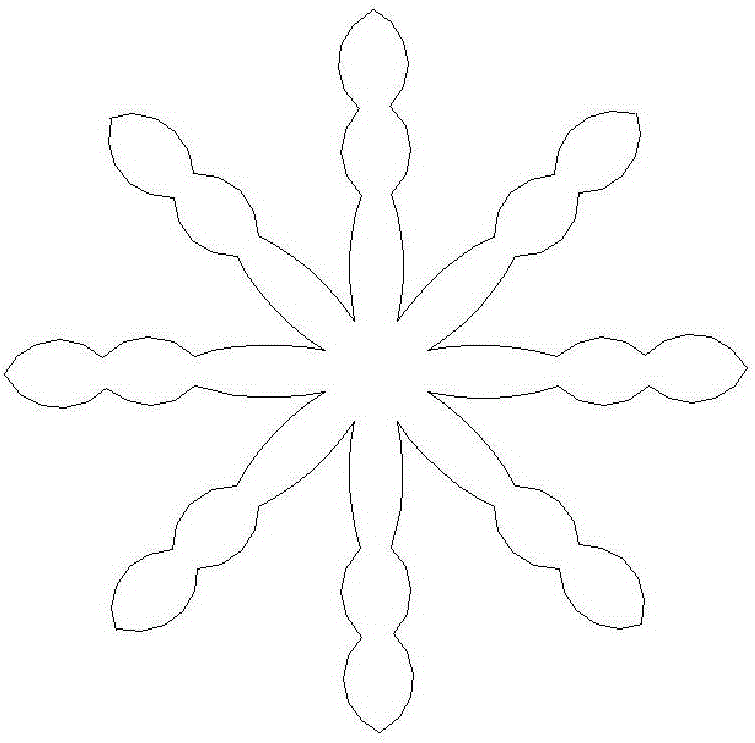

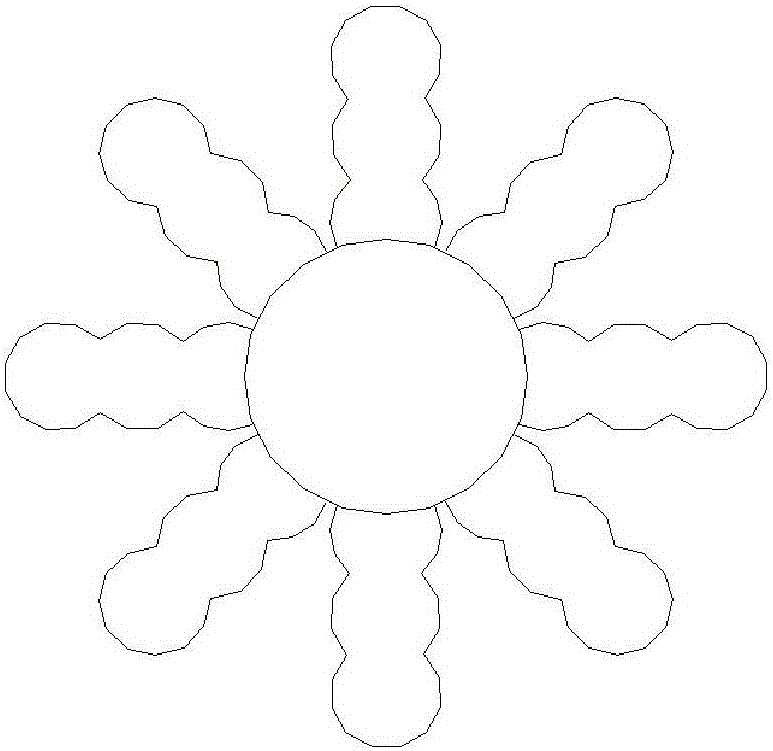

[0040] The cross-section of the polyester pre-oriented yarn in this embodiment is orange-shaped, which is composed of fibers with a "rice"-shaped cross-section and fibers with a petal-shaped cross-section; the fibers with a "rice"-shaped cross-section include the following mass ratio components : semi-dull polyester: antibacterial masterbatch = 1:0.02; the fiber with petal-shaped cross-section is composed of water-soluble polyester; wherein, the quality of water-soluble polyester accounts for 25% of the sum of the mass of water-soluble polyester and semi-dull polyester . The antibacterial masterbatch is prepared by blending nano-silver antibacterial agent and polyethylene terephthalate at a mass ratio of 1:1. The nano-silver antibacterial agent is nano-silver supported by nano-carrier zirconium phosphate, and the particle size is 100-200nm.

[0041] The preparation method of the polyester pre-oriented yarn in this embodiment includes: mixing the antibacterial masterbatch and ...

Embodiment 2

[0050] The cross-section of the polyester pre-oriented yarn in this embodiment is orange-shaped, which is composed of fibers with a "rice"-shaped cross-section and fibers with a petal-shaped cross-section; the fibers with a "rice"-shaped cross-section include the following mass ratio components : semi-dull polyester: nano-silver antibacterial agent=1:0.1; the fiber of petal-shaped section is made up of water-soluble polyester; wherein, the quality of water-soluble polyester accounts for 75% of the sum of water-soluble polyester and semi-dull polyester quality %. The antibacterial masterbatch is prepared by blending nano-silver antibacterial agent and polyethylene terephthalate at a mass ratio of 1:0.5. The nano-silver antibacterial agent is nano-silver supported by nano-carrier silicon dioxide, and the particle size is 100-200nm.

[0051] The preparation method of the polyester pre-oriented yarn in this embodiment includes: mixing the antibacterial masterbatch and semi-dull p...

Embodiment 3

[0059] The cross-section of the polyester pre-oriented yarn in this embodiment is orange-shaped, which is composed of fibers with a "rice"-shaped cross-section and fibers with a petal-shaped cross-section; the fibers with a "rice"-shaped cross-section include the following mass ratio components : semi-dull polyester: antibacterial masterbatch = 1:0.05; the fiber with petal-shaped cross-section is composed of water-soluble polyester; wherein, the quality of water-soluble polyester accounts for 40% of the sum of the mass of water-soluble polyester and semi-dull polyester . The antibacterial masterbatch is prepared by blending nano-silver antibacterial agent and polyethylene terephthalate at a mass ratio of 1:0.2. The nano-silver antibacterial agent is nano-silver supported by nano-carrier zirconium phosphate, and the particle size is 100-200nm.

[0060] The preparation method of the polyester pre-oriented yarn in this embodiment includes: mixing the antibacterial masterbatch an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com