Acrylic dye-retarding agent and preparation method thereof

A technology of dye inhibitor and acrylic fiber, which is applied in the field of acrylic fiber dye resist and its preparation, can solve the problems that the standards of EU countries cannot be met, it is difficult to achieve the dye resistance effect, and the preparation process is complicated, etc., and achieve excellent dye resistance effect, Improve the pass rate and avoid stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

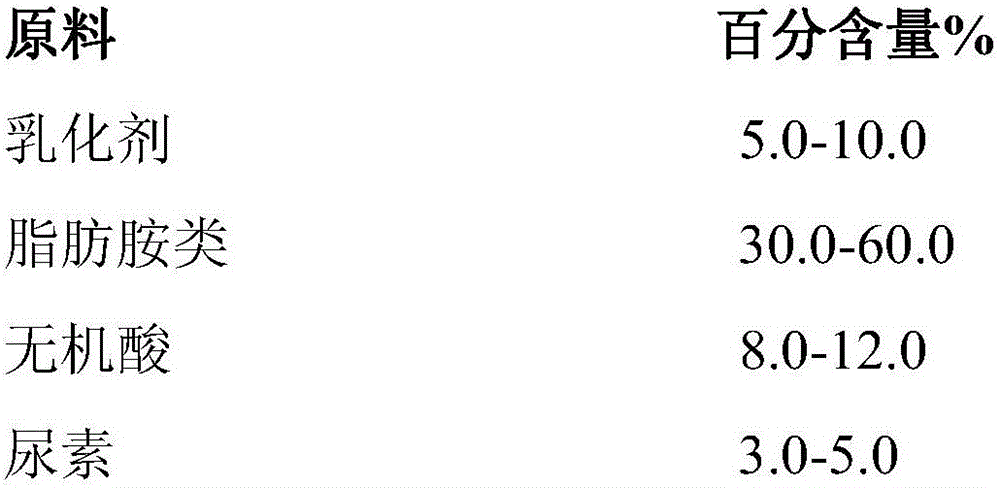

[0019] Acrylic fiber dye resist of the present invention, its mass percentage consists of:

[0020]

[0021]

[0022] The emulsifier is fatty alcohol polyoxyethylene ether; the fatty amines include fatty primary amines, secondary amines and tertiary amines; the inorganic acids include phosphoric acid, hydrochloric acid, sulfuric acid, and nitric acid.

Embodiment 2

[0024] Acrylic fiber dye resist of the present invention, its mass percentage consists of:

[0025]

[0026] The emulsifier is fatty alcohol polyoxyethylene ether; the fatty amines include fatty primary amines, secondary amines and tertiary amines; the inorganic acids include phosphoric acid, hydrochloric acid, sulfuric acid, and nitric acid.

Embodiment 3

[0028] Acrylic fiber dye resist of the present invention, its mass percentage consists of:

[0029]

[0030] The emulsifier is fatty alcohol polyoxyethylene ether; the fatty amines include fatty primary amines, secondary amines and tertiary amines; the inorganic acids include phosphoric acid, hydrochloric acid, sulfuric acid, and nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com