Waterproof construction method in underground engineering

A technology for underground engineering and construction methods, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of easily changing the law of groundwater runoff, waste of cost and resources, and destruction of vegetation, so as to reduce cost waste and quality problems, Effective seepage water barrier, improve the effect of anti-seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

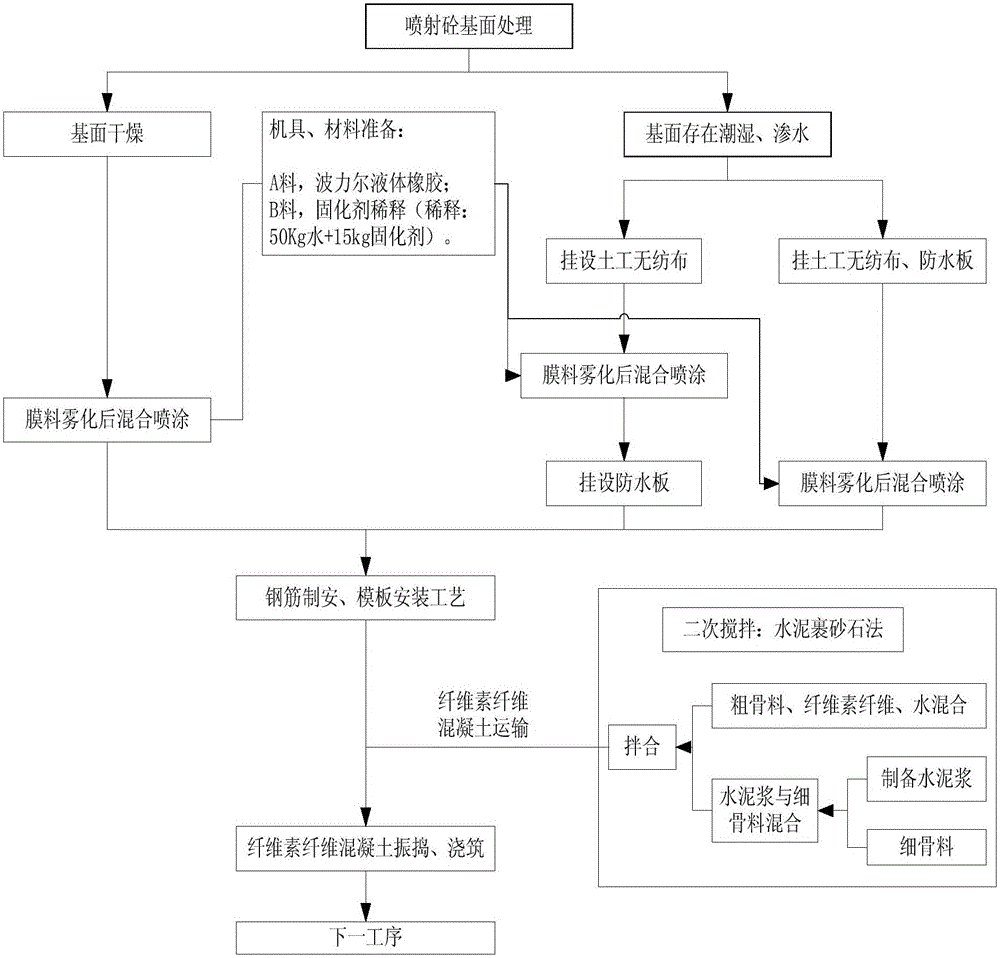

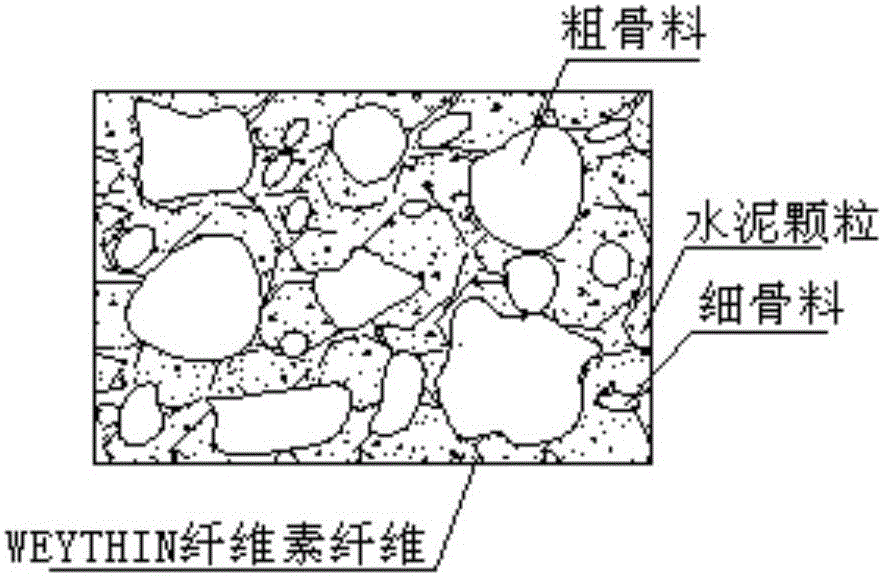

[0021] figure 1 It is a flow chart of the waterproof construction process of the preferred embodiment of the present invention; figure 2 It is a schematic diagram of the macrostructure of WEYTHIN cellulose fiber concrete in a preferred embodiment of the present invention.

[0022] Such as figure 1 and figure 2 As shown, the underground engineering waterproof construction method of the present embodiment includes the following steps: a, tunnel excavation, initial support and waterproof base surface treatment after the initial support; b, spray film material making; c, waterproof base surface Spraying with film-forming technology; d, steel reinforcement engineering construction; e, WEYTHIN cellulose fiber concrete mixing; f, WEYTHIN cellulose fiber concrete pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com