Alkalifying and diluting device for preventing sample blasting boiling of kjeldahl nitrogen determination instrument and method

A technology of Kjeldahl nitrogen determination and dilution device, which is used in the preparation of test samples, measurement devices, chemical method analysis, etc., can solve the problems of alkali pump not being able to normally inhale lye, increasing the cost burden of manufacturers, and error in test results. , to achieve the effect of solving the unstable measurement results, suppressing the bumping phenomenon, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

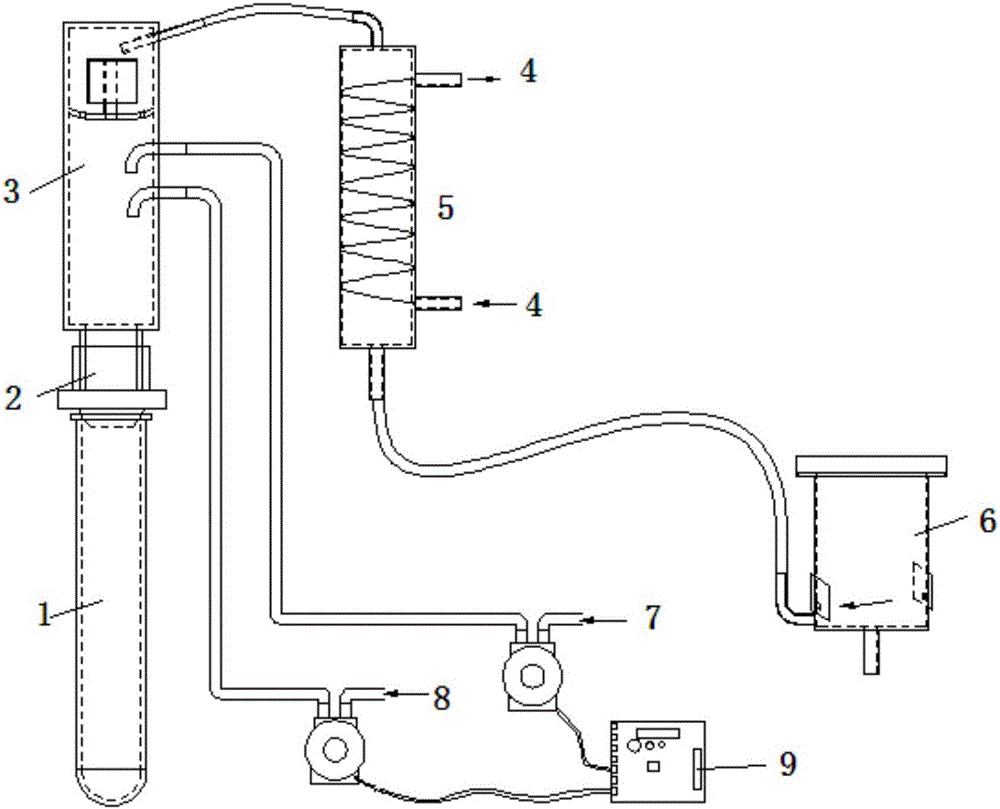

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

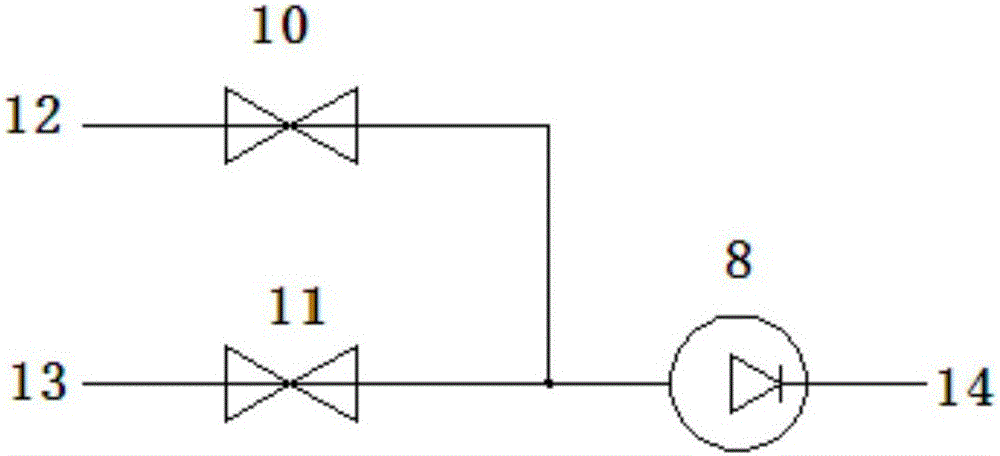

[0024] Such as figure 1 Shown, a kind of alkali-adding and diluting device that prevents Kjeldahl azotometer sample from bumping comprises a digestion tube 1, and a retort 3 communicated with the interior of the retort is installed at the top opening of the digestion tube 1, and the retort After a condenser 4 is connected in series at the top, it is connected with a titration cylinder 6. Meanwhile, the distilling bottle is also provided with lye and water inlets, and the lye or water inlets are respectively connected with water pumps and alkali pumps. The water pump 7 and the alkali pump 8 are controlled by a control device 9 . A distillation head 2 is provided at the mouth of the connecting pipe between the distillation bottle 3 and the digestion pipe 1 .

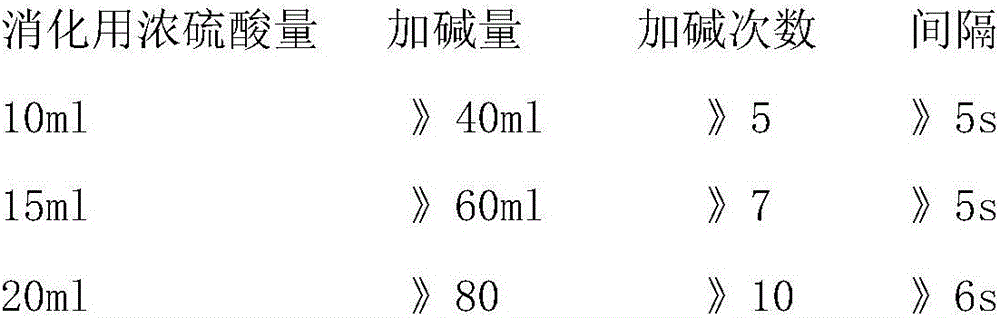

[0025] The input end of the control device 9 is provided with a display, and a data input module is provided on the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com