Negative pressure automatic control system for packaging box storage cabinet

An automatic control system and storage cabinet technology, applied in the direction of electric fluid pressure control, electrical program control, sequence/logic controller program control, etc., can solve the problem of short service life of fans and transmission parts, and the efficiency of cement pump trucks. Insufficient low reliability, low reliability, etc., to achieve the effects of saving fuel consumption, improving configuration and overall performance, and saving electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

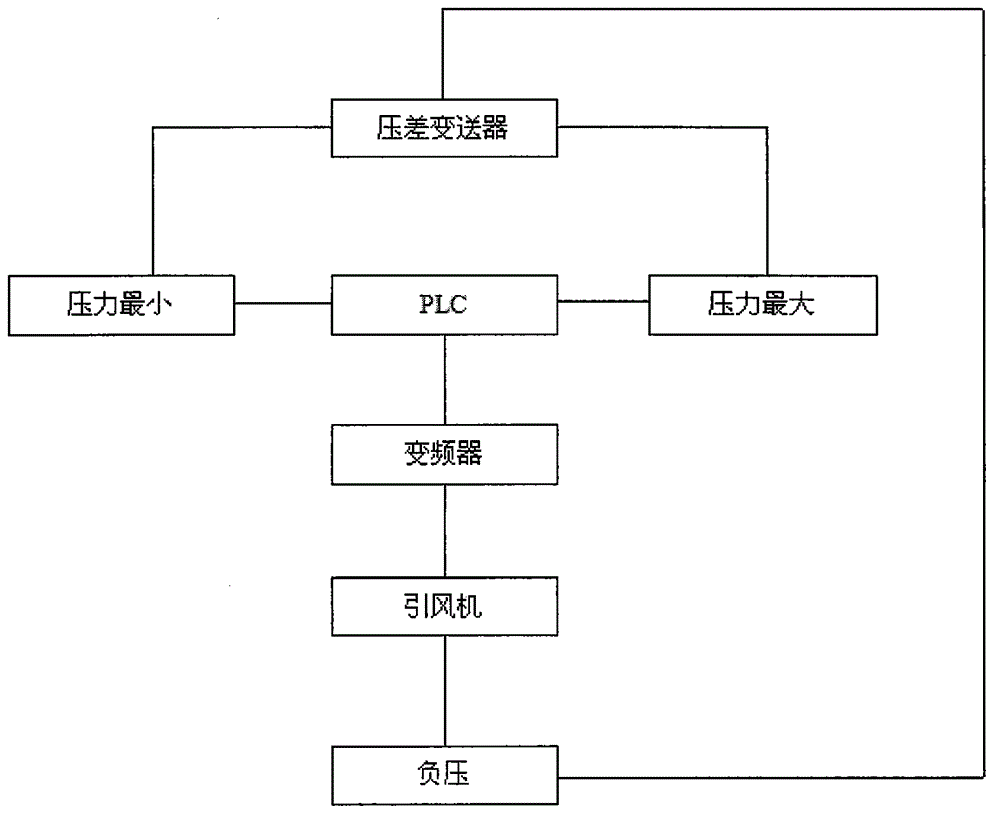

[0010] The present invention is a negative pressure automatic control system for a packing box storage cabinet, comprising a programmable logic controller s7-200, a frequency converter, a differential pressure transmitter and an induced draft fan, and the control signal of the programmable logic controller s7-200 The output terminal is connected to the control signal input terminal of the frequency converter, the signal output terminal of the frequency converter is connected to the signal input terminal of the induced draft fan, and the differential pressure transmitter is arranged in the pump of the cement pump truck Inside, the data output end of the differential pressure transmitter is connected with the data input end of the programmable logic controller.

[0011] Control The present invention adopts PLC plus the frequency conversion speed regulation of the induced draf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com