Solar cell string automatic superposition welding machine

A solar cell, fully automatic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as uneven soldering, reduced profit of component factories, and differences in aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

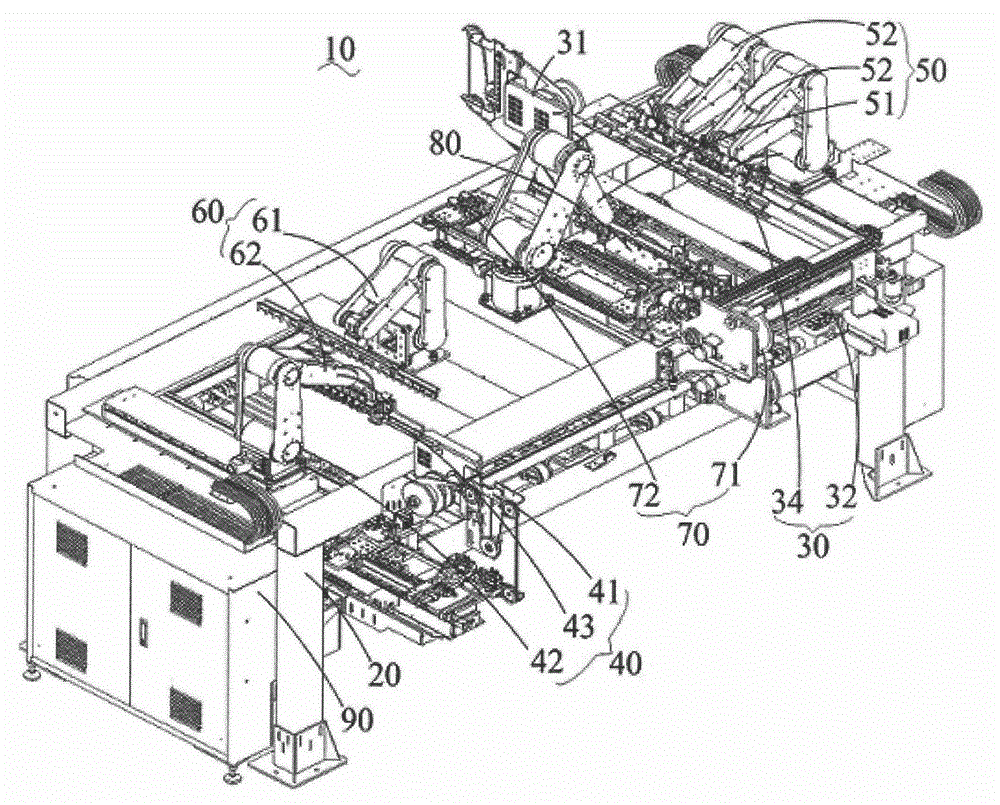

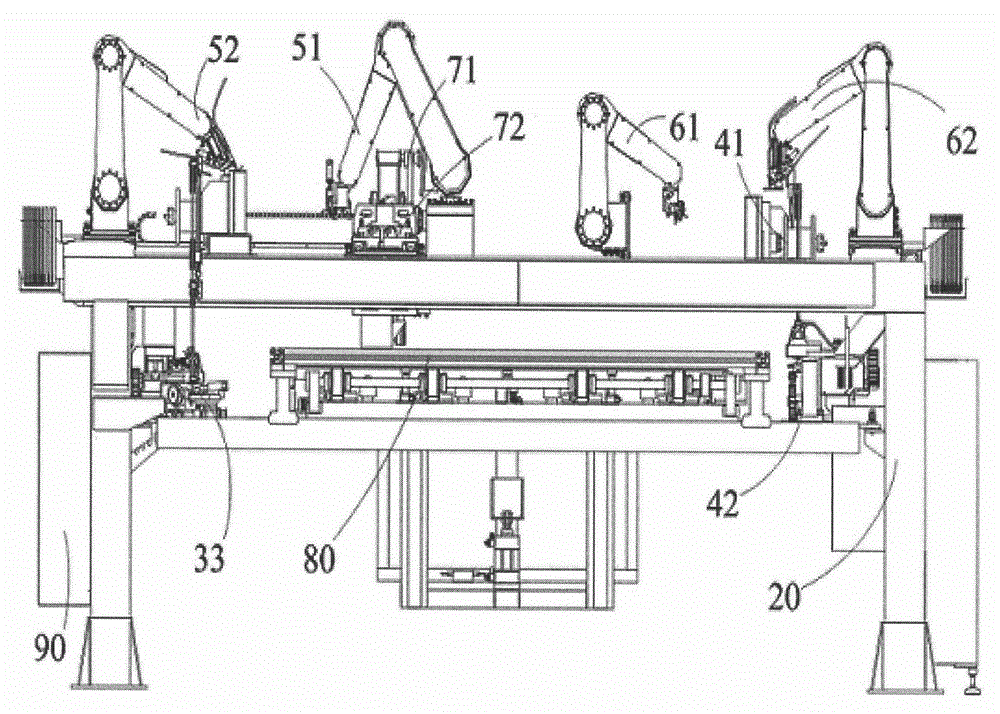

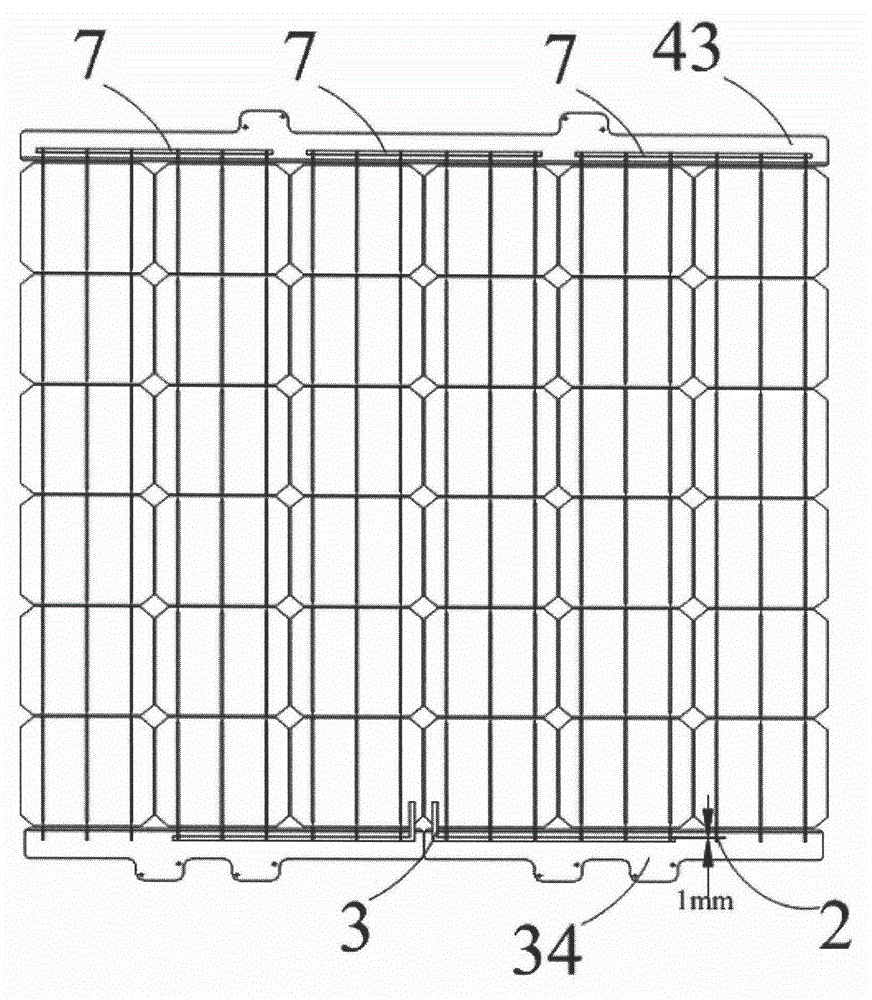

[0013] Such as figure 1 and figure 2 As shown, the solar battery string automatic stitching welding machine 10 includes a frame 20, a front-end confluence strip supply device 30, an end confluence strip supply device 40, a front-end confluence strip welding device 50, an end confluence strip welding device 60, and an insulating film supply device 70 , the battery string group carrying plate 80 and the control device 90 .

[0014] The front-end busbar supply device 30, the end busbar supply device 40, the front-end busbar welding device 50, the end busbar welding device 60, the insulating film supply device 70, and the battery string supporting plate 80 are arranged on the frame 20, and the front-end busbar The supply device 30 and the front-end confluence strip welding device 50 are located at the first end of the frame 20, and the front-end confluence strip supply device 30 is arranged on the side of the frame 20, and the front-end confluence strip welding device 50 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com