A kind of preparation device and preparation method of gel polymer lithium ion battery

A lithium-ion battery and gel polymer technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack parts, etc. Improved reliability and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

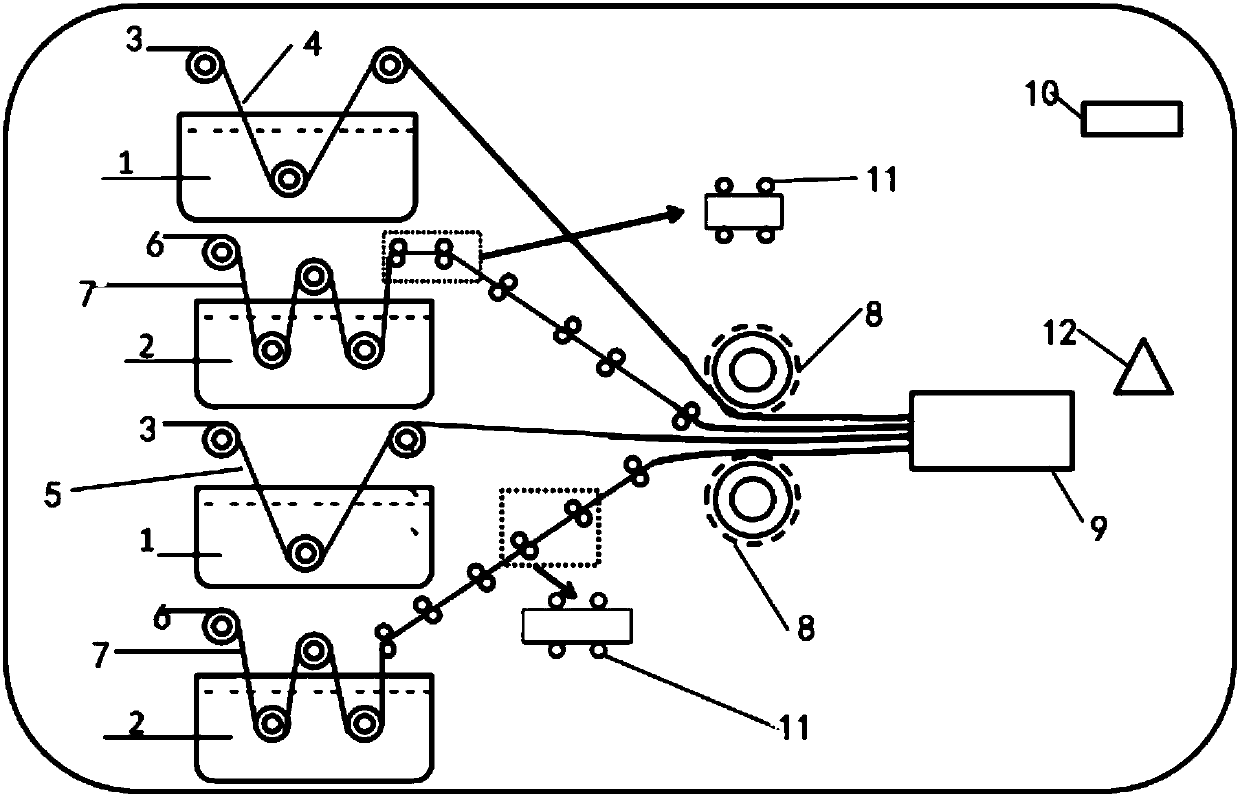

[0040] In this embodiment, a preparation device for a gel polymer lithium-ion battery is provided, please refer to figure 1 , figure 1 It is the structural diagram of the preparation device of the gel polymer lithium ion battery in the embodiment of the present application, such as figure 1 As shown, the device includes:

[0041] A container group, the container group comprising: two first containers 1 and two second containers 2, electrolyte solution is housed in the two first containers 1; gel is housed in the two second containers 2 Electrolyte precursor fluid;

[0042] Two sets of first pulley sets 3, the two sets of first pulley sets 3 are respectively wound with a positive pole piece 4 and a negative pole piece 5; the two sets of first pulley sets 3 are partially located in the two sets of first containers 1, When the two sets of first pulley sets 3 rotate, the positive pole piece 4 and the negative pole piece 5 are driven to soak in the electrolyte;

[0043]Two sets...

Embodiment 2

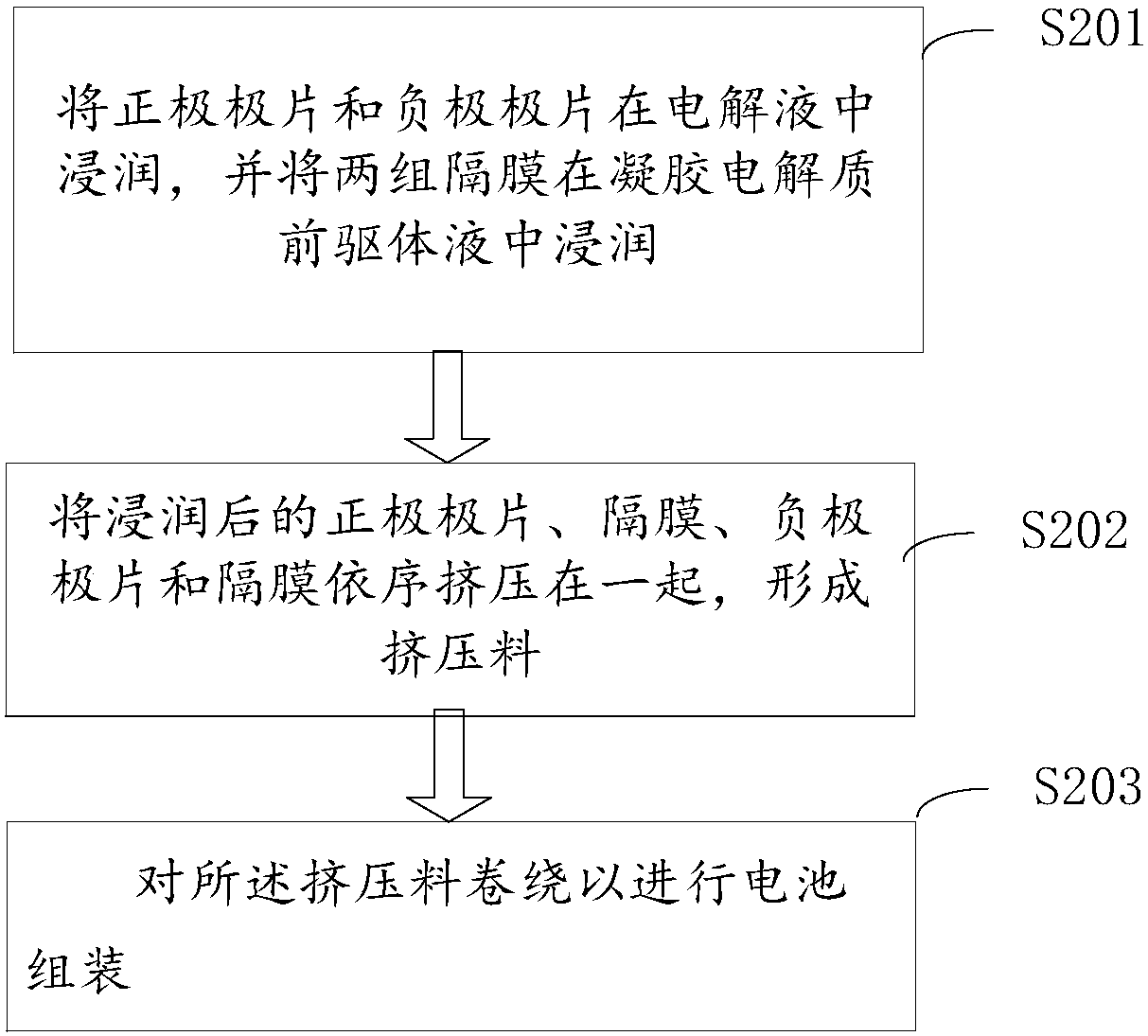

[0069] Provide a kind of preparation method of gel polymer lithium ion battery in this embodiment, please refer to figure 2 , figure 2 It is a flow chart of the preparation method of the gel polymer lithium ion battery in the embodiment of the present application, such as figure 2 As shown, the method includes:

[0070] Step S201, soaking the positive pole piece and the negative pole piece in the electrolyte, and soaking the two sets of separators in the gel electrolyte precursor liquid;

[0071] Step S202, extruding the infiltrated positive electrode sheet, separator, negative electrode sheet and separator together in sequence to form an extrusion material;

[0072] Step S203, winding the extruded material for battery assembly.

[0073] In the embodiment of the present application, before soaking the positive pole piece and the negative pole piece in the electrolyte, it further includes: performing dewatering and dust removal treatment on the positive pole piece and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com