Sintered oxide and semiconductor device

A technology of sintered bodies and oxides, which is applied in the manufacture of oxide conductors, semiconductor devices, semiconductor/solid-state devices, etc., and can solve the problem that the conduction current ratio cannot be fully increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

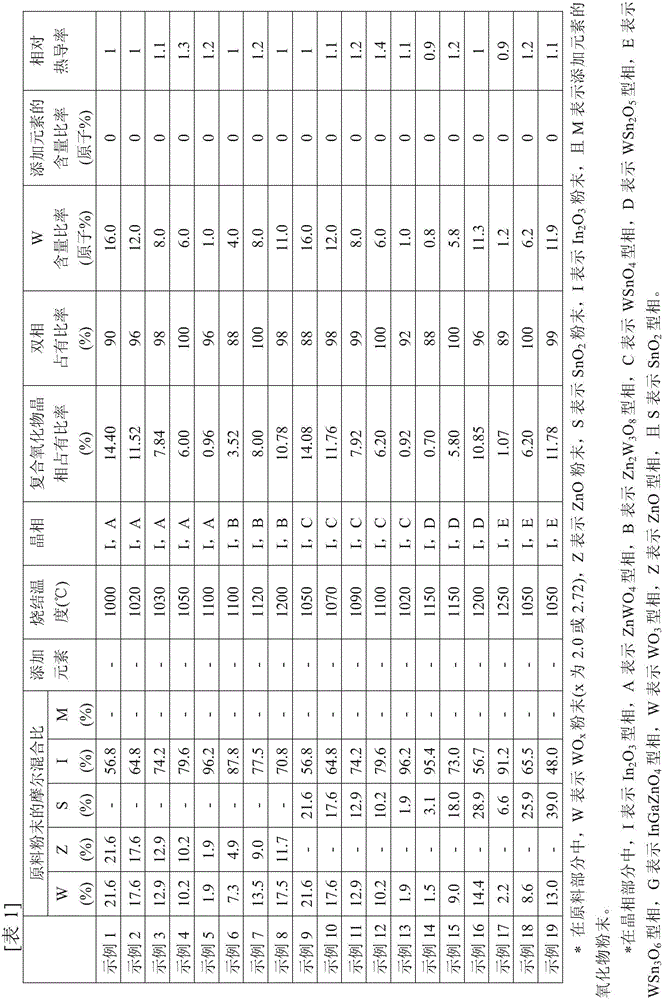

[0031] [First embodiment: oxide sintered body]

[0032] An oxide sintered body as an embodiment of the present invention is an oxide sintered body including at least one of zinc and tin, indium, and tungsten, wherein the oxide sintered body includes a composite oxide crystal phase as a crystal phase, the The composite oxide crystal phase includes at least one of zinc and tin and tungsten. The oxide sintered body of the present embodiment includes, as a crystal phase, a composite oxide crystal phase including at least one of zinc and tin and tungsten, so in a TFT (thin film transistor), it is possible to make the off-state current The TFT (Thin Film Transistor) is a semiconductor device including an oxide semiconductor film formed by using an oxide sintered body as a channel layer, which reduces and can increase the ratio of ON current to OFF current at a low driving voltage. In addition, the thermal conductivity of the oxide sintered body can be increased.

[0033] (includin...

no. 2 approach

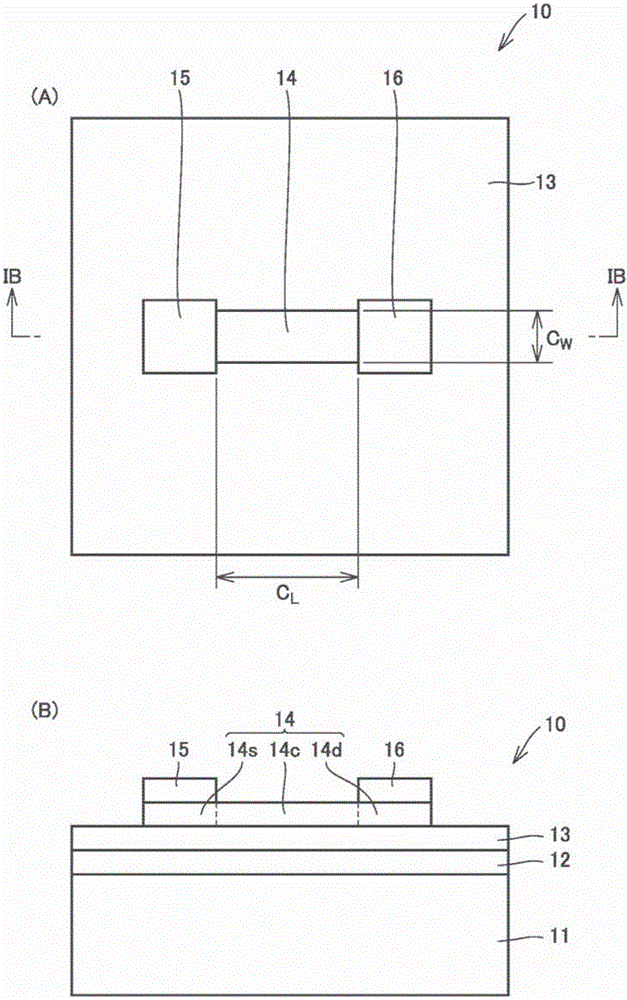

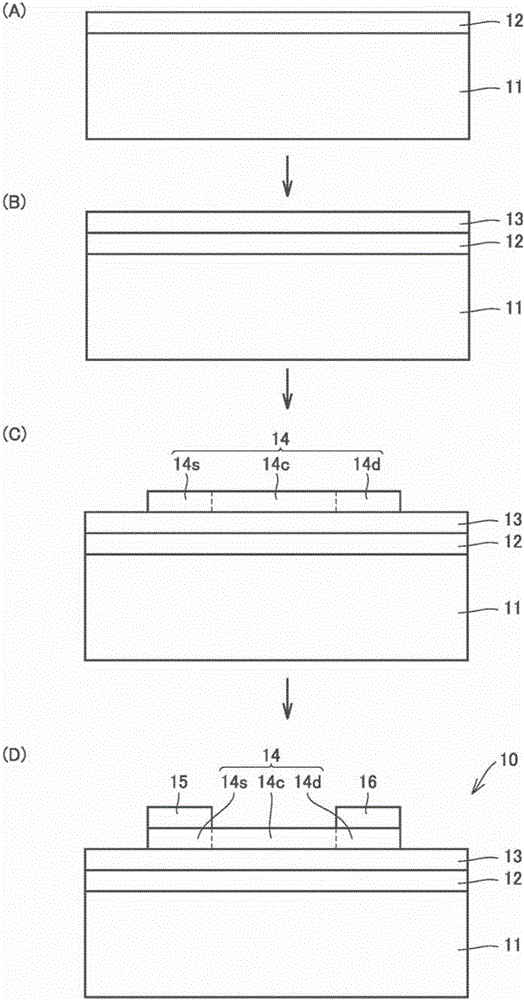

[0073] [Second Embodiment: Semiconductor Device]

[0074] refer to figure 1 , a semiconductor device 10 as another embodiment of the present invention includes an oxide semiconductor film 14 formed by a sputtering method using the oxide sintered body of the first embodiment as a target. Since the semiconductor device of the present embodiment includes the oxide semiconductor film formed by the sputtering method using the oxide sintered body of the above-described embodiment as a target, the semiconductor device of the present embodiment has high characteristics.

[0075] Although the semiconductor device 10 of the present embodiment is not particularly limited, the semiconductor device 10 of the present embodiment is, for example, a TFT (Thin Film Transistor) that includes the oxide sintered body by using the first embodiment as a target A semiconductor device in which the oxide semiconductor film 14 formed by the sputtering method is used as a channel layer. Since the TFT as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com