Device for cleaning summer sleeping mats and other articles

A technology for articles and mats, applied in the field of cleaning devices, can solve the problems of unfavorable health, troublesome cleaning of carpet dirt and color stains, and insufficient cleaning, and achieves the effect of occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described now in conjunction with accompanying drawing.

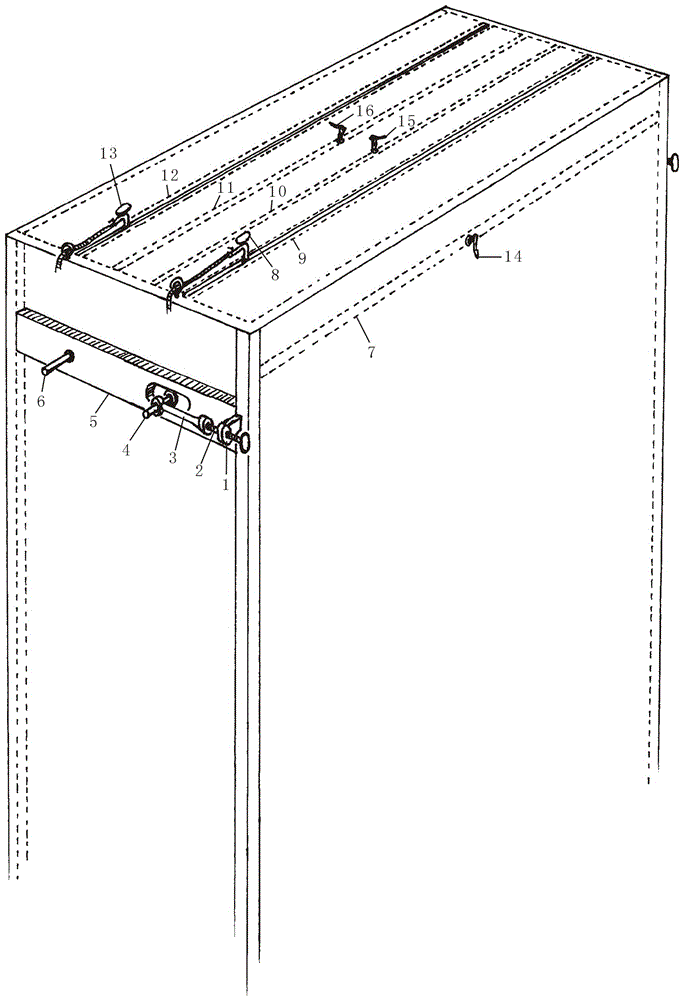

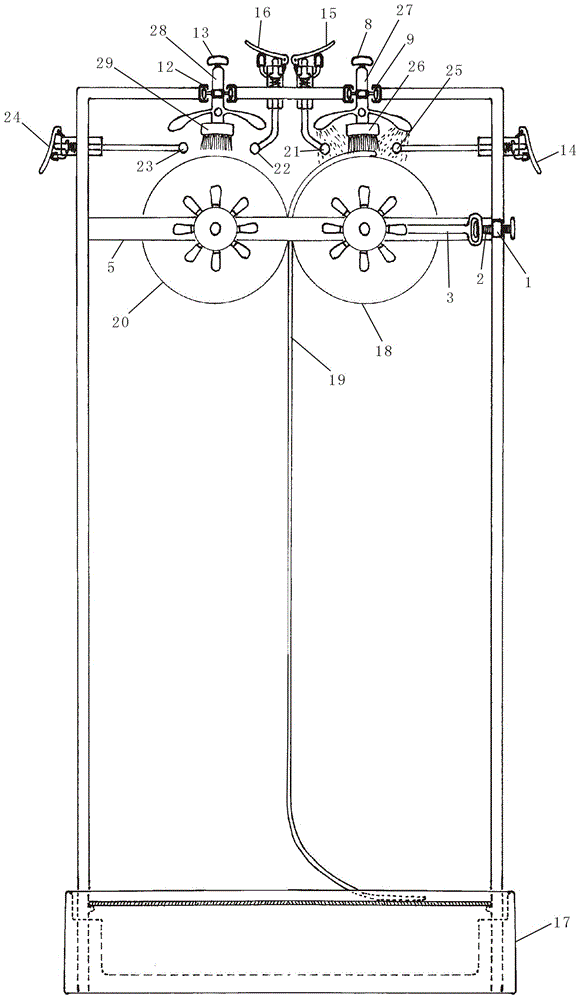

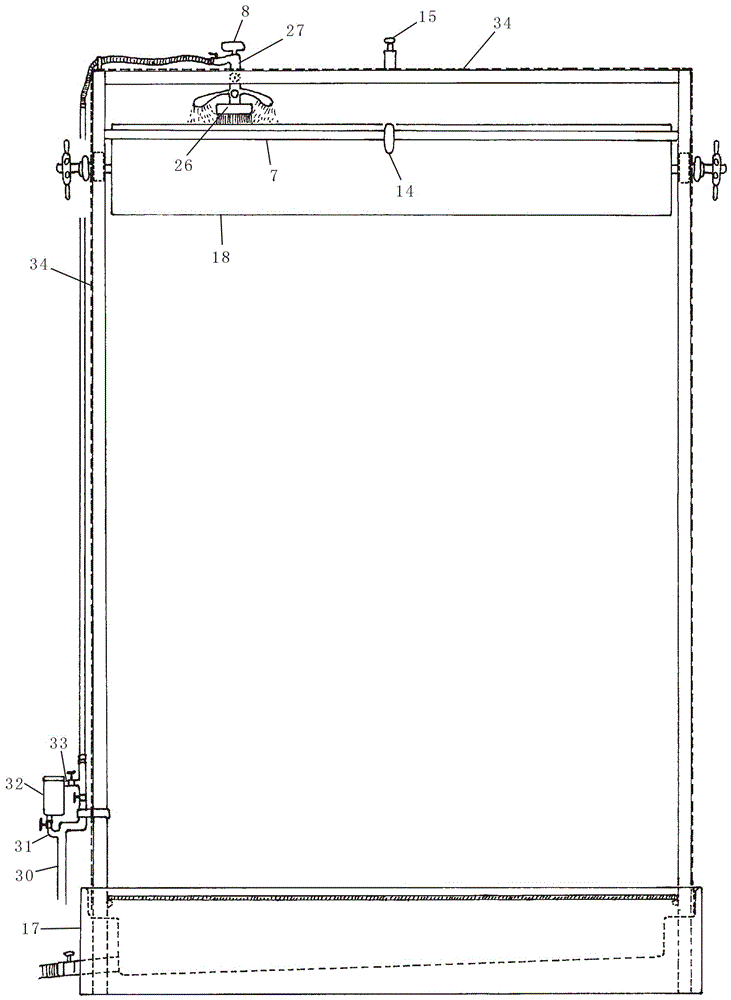

[0022] Such as Figure 1-4 As shown in the figure, 1. nut, 2. screw rod, 3. push-pull rod, 4. the first rotating shaft, 5. the left frame, 6. the second rotating shaft, 7. the third crosspiece, 8. the first handle, 9 .The first slide, 10. The first rung, 11. The second rung, 12. The second slide, 13. The second handle, 14. The third wrench, 15. The first wrench, 16. The second wrench , 17. Sink, 18. The first roller, 19. Mat, 20. The second roller, 21. The first horizontal axis, 22. The second horizontal axis, 23. The fourth horizontal axis, 24. The fourth wrench, 25. The third horizontal axis, 26. the first brush, 27. the first water pipe, 28. the second water pipe, 29. the second brush, 30. the water inlet pipe, 31. the water inlet branch pipe, 32. the lotion tank, 33. Outlet pipe, 34. cover.

[0023]A device for cleaning mats 19 and other items, which is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com