Cleaning method and back-side defect reworking method for large-size sapphire substrate before annealing

A sapphire, large-scale technology, applied in the cleaning method using tools, cleaning methods using liquid, cleaning methods and utensils, etc., can solve problems such as bad rework, yield rate below 50%, unclean surface cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

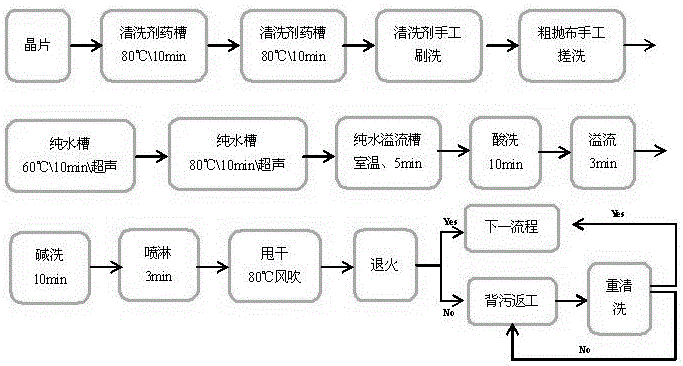

Method used

Image

Examples

Embodiment 1

[0033] After the 25 ground sapphire substrates were rinsed with electronic-grade pure water, after 10 minutes of ultrasonic cleaning in two ultrasonic water tanks containing detergent at 80°C, use a long-haired brush to stick an appropriate amount of detergent to the substrates. After scrubbing, scrub with coarse throwing cloth, and then use ultrasonic cleaning for 10 minutes in overflow mode. Finally, dry the substrate and inspect it visually under strong light. The test results show that 24 pieces are qualified, 1 piece has a color difference, and the yield rate reaches 96%.

Embodiment 2

[0037] After the 25 ground sapphire substrates were rinsed with electronic-grade pure water, they were cleaned in two 80°C ultrasonic water tanks containing detergent for 10 minutes; Substrates are manually scrubbed and then scrubbed with coarse throwing cloth; (3) use overflow ultrasonic cleaning for 10 minutes; (4) electronic grade pure water at 80°C for 10 minutes, and then put into pure water overflow ultrasonic tank 5 minutes, the water temperature is room temperature; (5) use H 2 SO 4 and H 2 o 2 The ratio of the 100°C mixed solution is 2:1:7, corrode the wafer for 5 minutes, and then overflow with pure water for 3 minutes; (6) use NH 4 OH and H 2 o 2 The ratio of the mixed solution is 1:1:7, and the wafer is etched for 5 minutes; (7) The wafer is sprayed with electronic-grade pure water for 3 minutes, then heated and dried, and put into an annealing furnace; 1 black dot, 1 small collapse. The yield rate reached 92%.

Embodiment 3

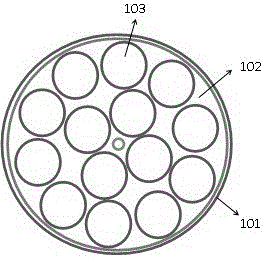

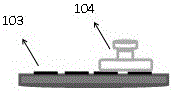

[0041]Take 25 pieces of bad reworked sheets on the back, place the back side up on the 103 substrate sheet placement position shown in Figure 1, take 30ml of the slurry with abrasive SiC:suspending agent:pure water=500:400:1500ml and spread evenly on the After grinding the substrate on the device for 15 minutes with a cast iron grinding disc, stick a coarse throw cloth on the grinding disc and grind for 5 minutes, then wash the ground 25 sapphire substrates with electronic grade pure water, and pass through two Do not turn on ultrasonic cleaning for 10 minutes in an ultrasonic water tank containing cleaning agent at 80°C. Use a long-haired brush to stick an appropriate amount of detergent to the substrate and scrub it manually, then scrub it with a coarse throw, use an overflow method for ultrasonic cleaning for 10 minutes, and then put it in electronic-grade pure water at 80°C for 10 minutes, then put it in pure water In the overflow ultrasonic tank for 5 minutes, the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com