Pathogen sewage treatment material and use method for same

A technology for sewage treatment and pathogens, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of virus penetration, parasitic pathogenic microorganisms, and poor removal of impurities. , to achieve the effect of protecting the environment, easy to use, and effective penetration and sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

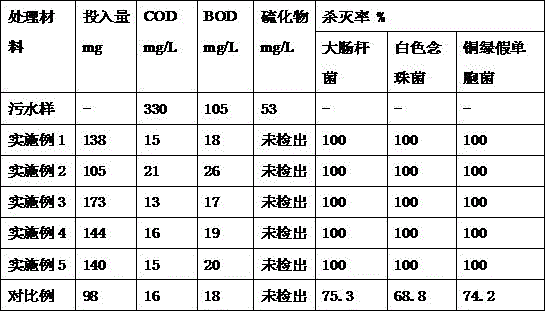

Examples

Embodiment 1

[0017] Embodiment 1: A kind of pathogen sewage treatment material, comprises the raw material of following parts by weight: 50 parts of composite flocculants, 40 parts of composite fungicides, 15 parts of modified attapulgite, 12 parts of sodium carboxymethyl cellulose, porous type 4 parts of hydroxyapatite powder, 5 parts of polyepichlorohydrin, 12 parts of polyamino polyether methylene phosphonic acid (PAPEMP);

[0018] The composite flocculant is cationic polyacrylamide, polysilicate ferric chloride and sodium polyethyleneimine xanthate, the mass ratio of which is 2:5:3; the composite fungicide is dichloroiso Sodium cyanurate, polyhexamethylene biguanide water, the mass ratio is 2:5:15.

[0019] Further, the preparation method of the modified attapulgite is as follows: take the attapulgite with a particle size of 50-300 mesh, use a deionized water bath for ultrasonication, and dry at 100°C, use acetic acid as a catalyst, trifluoropropyltrimethoxy Silane was used as a modif...

Embodiment 2

[0021] Embodiment 2: Pathogenic sewage treatment materials, including the following raw materials in parts by weight: 40 parts of composite flocculants, 30 parts of composite bactericides, 10 parts of modified attapulgite, 10 parts of sodium carboxymethyl cellulose, porous hydroxyphosphorus 2 parts of limestone powder, 3 parts of polyepichlorohydrin, 10 parts of polyamino polyether methylene phosphonic acid (PAPEMP);

[0022] The composite flocculant is cationic polyacrylamide, ferric chloride polysilicate and sodium polyethyleneimine xanthate, the mass ratio of which is 1:2:1; the composite fungicide is dichloroiso The mass ratio of sodium cyanurate, polyhexamethylene biguanide and water is 1:2:5.

[0023] Further, the preparation method of the modified attapulgite is the same as that in Example 1.

[0024] The method of using the pathogen sewage treatment material is as follows: first mix the prepared cationic polyacrylamide, polysilicate ferric chloride and polyethyleneimi...

Embodiment 3

[0025] Embodiment 3: Pathogenic sewage treatment materials, including the following raw materials in parts by weight: 60 parts of composite flocculants, 50 parts of composite bactericides, 20 parts of modified attapulgite, 15 parts of sodium carboxymethylcellulose, porous hydroxyphosphorus 6 parts of limestone powder, 7 parts of polyepichlorohydrin, 15 parts of polyamino polyether methylene phosphonic acid (PAPEMP);

[0026] The composite flocculant is cationic polyacrylamide, ferric chloride polysilicate and sodium polyethyleneimine xanthate, the mass ratio of which is 1:3:2; the composite fungicide is dichloroiso The mass ratio of sodium cyanurate, polyhexamethylene biguanide and water is 1:3:5.

[0027] Further, the preparation method of the modified attapulgite is the same as that in Example 1.

[0028]The method of using the pathogen sewage treatment material is as follows: first mix the prepared cationic polyacrylamide, polysilicate ferric chloride and polyethyleneimine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com