Method for reutilization of water resources and transformation and utilization of salt in waste water

A technology for water resources and waste water, applied in chemical instruments and methods, water softening, water/sewage treatment, etc., can solve problems that do not involve resource utilization, water pollution, secondary soil pollution, etc., and achieve energy saving and protection Environmental and treatment cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

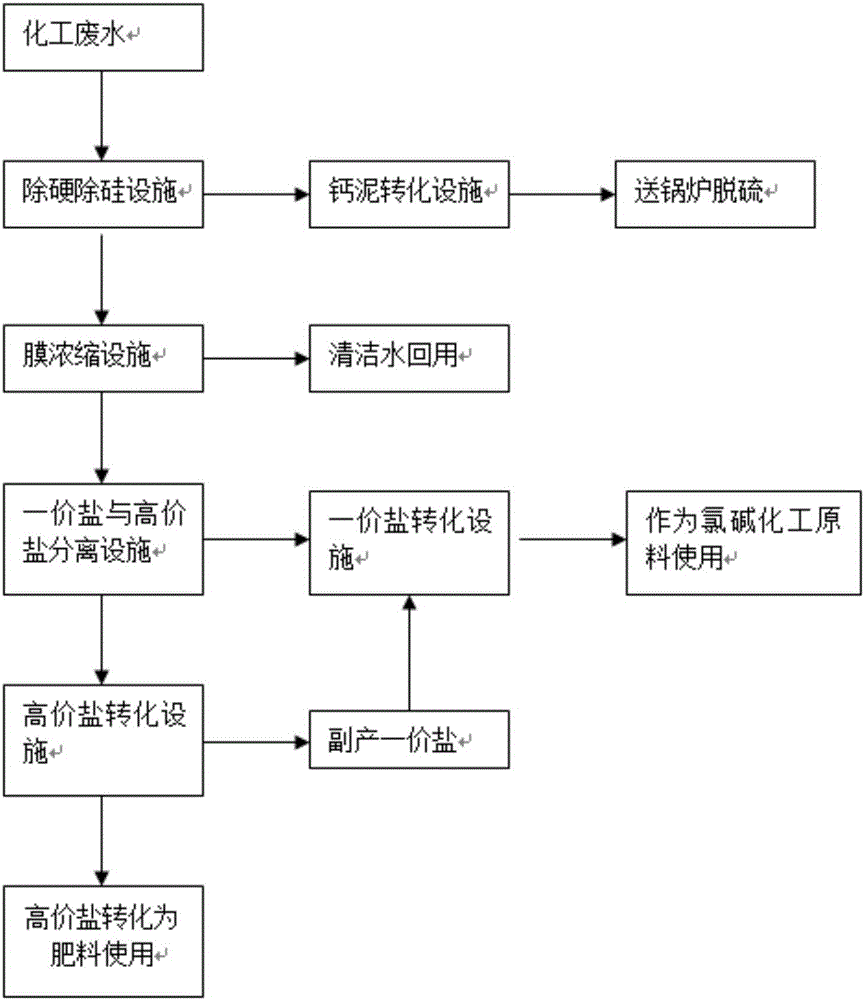

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] like figure 1 (1) Hard and silicon removal facilities: the waste water is adjusted to a pH of more than 10 by adding caustic soda in the hard and silicon removal unit, and the hardness ions such as calcium, magnesium and silicon in the waste water are removed by using the original carbonate and bicarbonate in the water. When the original carbonate and bicarbonate in the wastewater are insufficient, carbon dioxide is introduced into the wastewater to completely remove the hardness ions in the wastewater, and the produced calcium carbonate, magnesium hydroxide, silicate, etc. are separated from the water through clarification and filtration. After the sludge is dried, it is pulverized into 2-6mm particles as boiler desulfurizer.

[0021] (2) Membrane concentration facility: The waste water after hard and silicon removal is filtered by ultrafiltrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com