Solid polymer electrolyte electrolytic bath

A solid polymer, electrolytic cell technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of sealing system collapse, electrode material failure, carbon paper corrosion, etc., to prevent oxidative corrosion, improve catalytic efficiency, and simplify the system. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

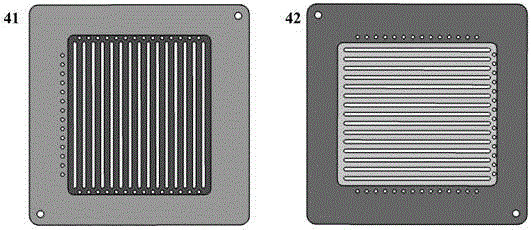

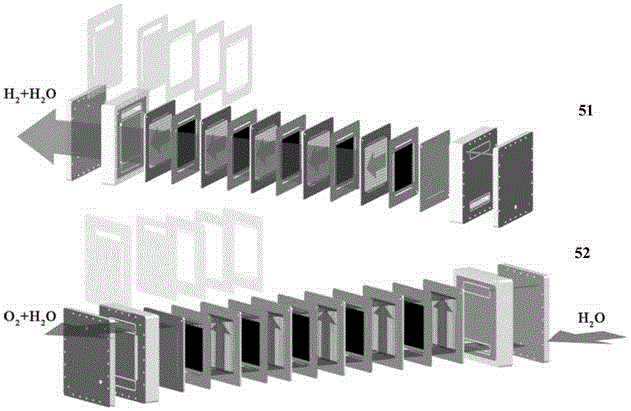

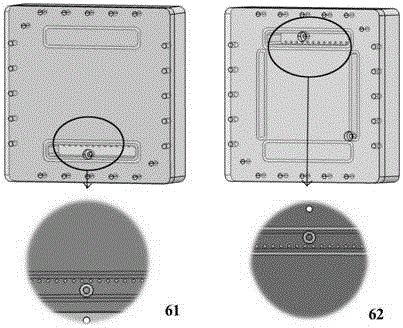

[0038] figure 2 Shown is a schematic structural view of a solid polymer electrolyte electrolyzer according to an embodiment of the present invention, the electrolyzer consists of an output end outer plate 21, an output end end plate 22, an output end pole plate 23, a membrane electrode 24, a bipolar plate 25, The input end plate 26, the input end end plate 27, the input end outer plate 28, the sealing member 29, and the positioning rod 210 are composed. The assembly is tightened and pressurized by evenly distributed bolts, and the loading pressure is controlled by the tightening torque of the nuts. Among them, the outer plates 21 and 27 are made of corrosion-resistant stainless steel metal, with bolt through holes evenly distributed on the periphery, and a pair of positioning rod through holes are arranged at diagonal positions; the end plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com