Water solubility resisting PVA nanofiber composite fabric and preparation method thereof

A composite fabric and nanofiber technology, which is applied in spinning solution preparation, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problems of easy separation, difficult complete bonding, and less research, so as to achieve stable structure and performance, Improves service life and prevents separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of water-soluble PVA nanofiber composite fabric, comprising the steps of:

[0032] (1) Pretreatment of base fabric: spinning nylon (54g / m 2 ) cut into a 30cm×100cm sample, and pretreat it with plasma, the processing power is 200w, and the processing time is 3min;

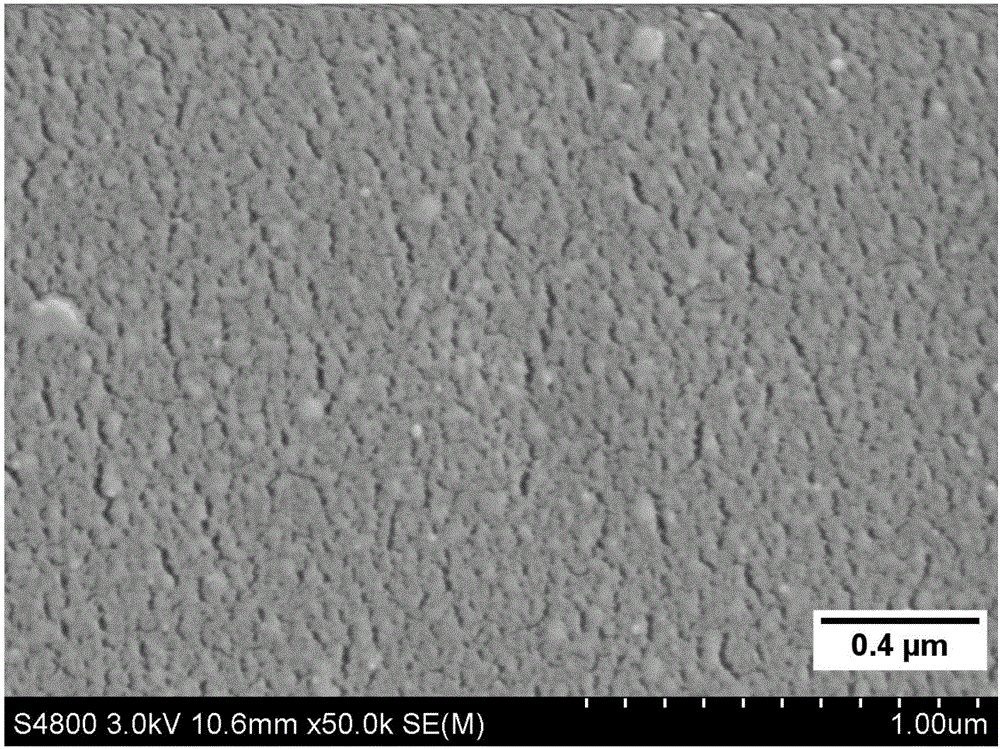

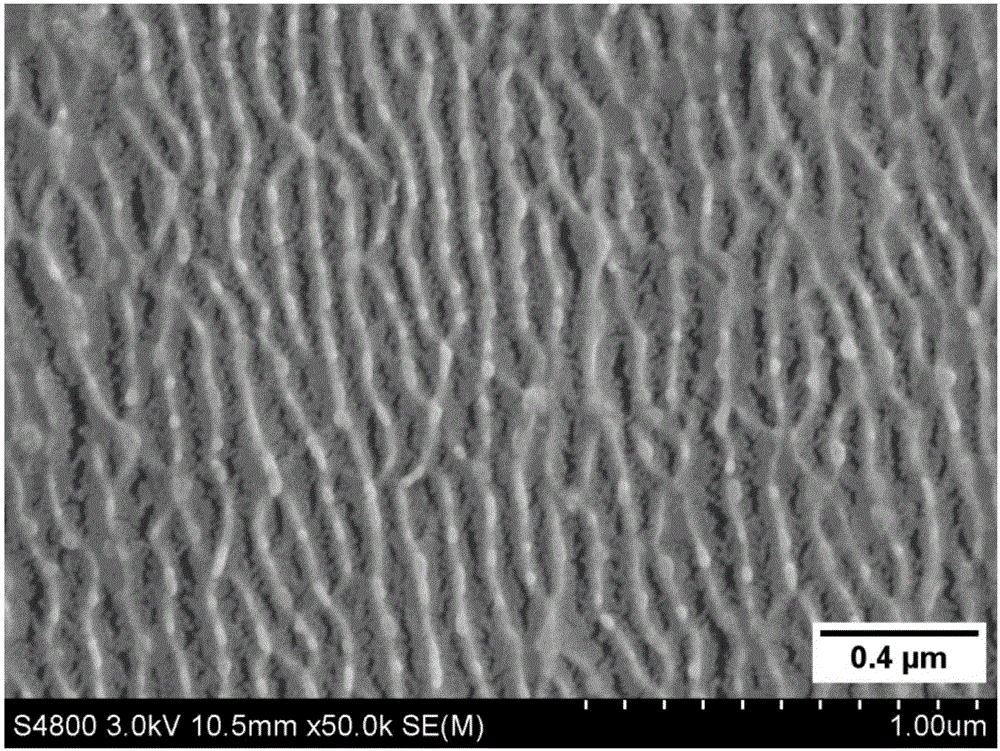

[0033] see figure 1 and figure 2 After the pretreatment of the base fabric, the surface roughness of the fiber in the nylon fiber is significantly improved, forming a large number of nano-scale unevenness, which is conducive to the bonding with the nanofiber;

[0034] (2) Preparation of PVA spinning solution: take 25 g of PVA with a molecular weight of 95,000, add 225 g of deionized water, and use a constant temperature magnetic stirrer for 3 hours at 90° C. to obtain a high molecular weight PVA solution I with a mass fraction of 10%; Weigh 100g of PVA with a molecular weight of 20,000-30,000, add 300g of deionized water, and use a constant temperature magnetic stirrer for 3.5h at 90°...

Embodiment 2

[0040] A preparation method of water-soluble PVA nanofiber composite fabric, comprising the steps of:

[0041] (1) Base fabric pretreatment: electric spinning (65g / m 2 ) for plasma pretreatment with a processing power of 300w and a processing time of 3min.

[0042] (2) Prepare PVA spinning solution: make PVA spinning solution as described in step (2) in Example 1.

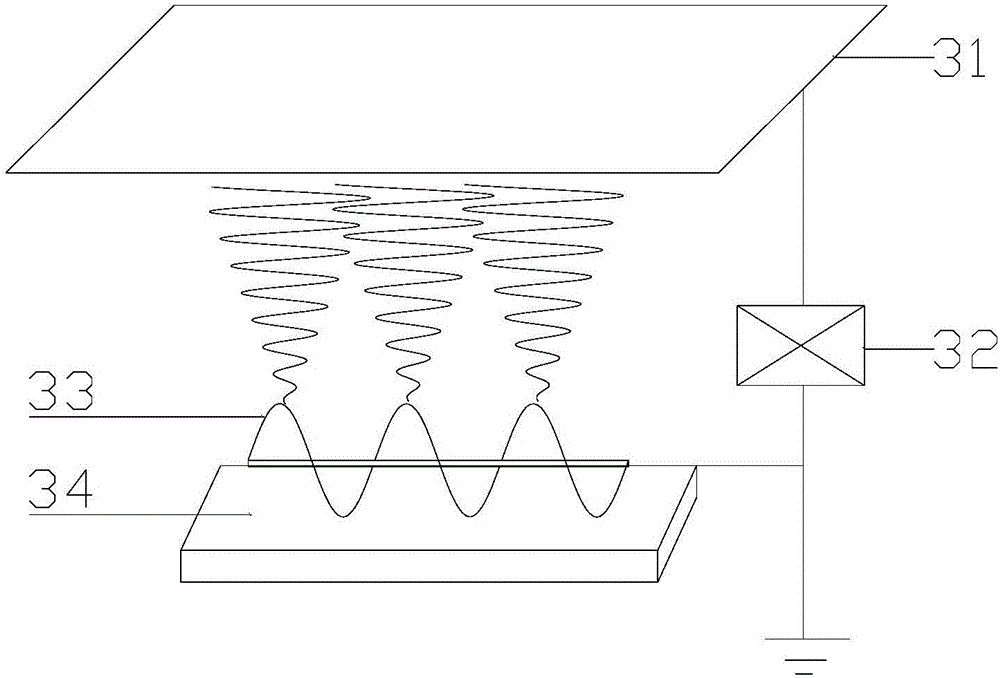

[0043](3) Preparation of composite fabric: Fix the electrospinning through plasma pretreatment on the receiving drum of the spiral flake electrospinning machine, pour the prepared PVA solution into the semi-cylindrical solution tank, turn on the power, and pass The control panel sets the spinning voltage to 70kV, the generator speed to 15r / min, the spinning distance to 170mm, and the receiver speed to 1.5m / min. The helix rotates at the set speed in the solution tank containing the spinning solution, so that the spinning solution adheres to the tip of the helix and brings the liquid to the spinning area, forming a...

Embodiment 3

[0048] A preparation method of water-soluble PVA nanofiber composite fabric, comprising the steps of:

[0049] (1) Base fabric pretreatment: polyester taffeta (60g / m 2 ) for plasma pretreatment, processing power 250w, processing time 5min;

[0050] (2) prepare PVA spinning solution: make PVA spinning solution as described in step (2) in embodiment one;

[0051] (3) Preparation of composite fabric: fix the polyester taffeta that has undergone plasma pretreatment on the receiving drum of the spiral sheet electrospinning machine, pour the prepared PVA solution into the semi-cylindrical solution tank, and turn on the power , set the spinning voltage to 80kV, the generator speed to 20r / min, the spinning distance to 160mm, and the receiver speed to 2m / min through the control panel. The helix rotates at a set speed in the solution tank filled with spinning solution, so that the spinning solution is attached to the tip of the helix and the liquid is brought to the spinning area, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com