Cotton-containing knitted fabric and dyeing method thereof

A dyeing method and technology of cotton knitted fabrics, applied in the field of textile production, can solve problems affecting product quality, fabric surface scratches, long running time, etc., and achieve the effects of improving product quality, reducing rework costs, and reducing scratches and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

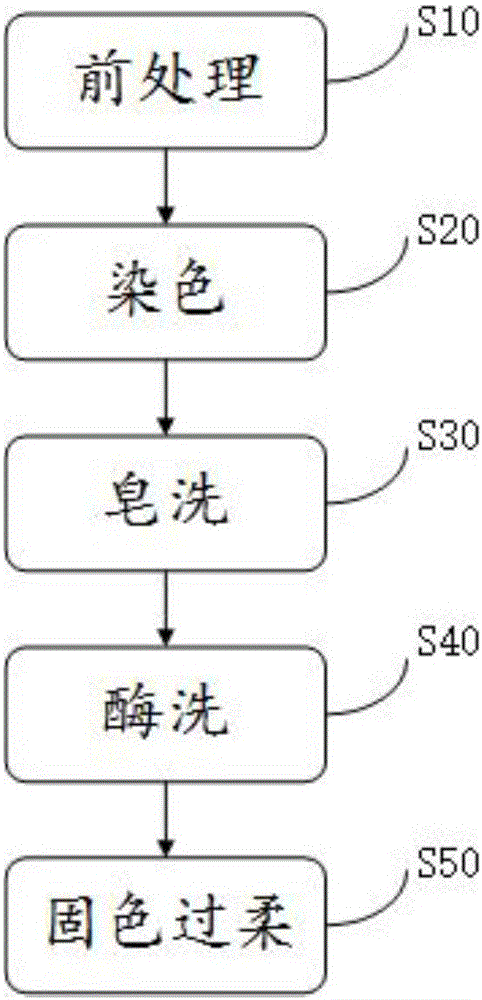

[0036] A kind of dyeing method of cotton-containing knitted fabric of the present embodiment comprises the following steps:

[0037] Pre-treatment: add caustic soda 4g / L, hydrogen peroxide 3.6g / L, and penetrant 0.5g / L to the main tank of the dyeing machine, then heat up to 98 degrees, run for 45 minutes, cool down and drain water, add acetic acid 1g / L after washing with water twice L and deoxygenase 0.12g / L, drain water after running for 10 minutes, and end the pretreatment step.

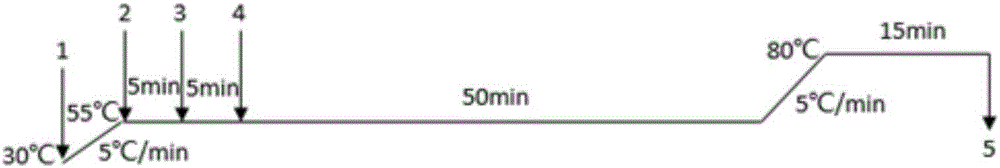

[0038] Dyeing: After the main vat of the dyeing machine is filled with water, add 80g / L of sodium sulfate, then raise the temperature to 60 degrees, add 5% dye, and run for 30 minutes, add 25g / L of soda ash, continue to run for 45 minutes, and drain to complete the dyeing step.

[0039] Soaping: Wash the main tank of the dyeing machine three times with water, then add soaping agent 1g / L into the water and raise the temperature to 90°C, run for 10 minutes, drain, then wash with water twice, drain, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com