A boiler full oxygen combustion process

An all-oxygen combustion and boiler combustion technology, applied in the combustion method, combustion equipment, fuel supply and other directions, can solve problems such as denitration, and achieve the effect of convenient normal use and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

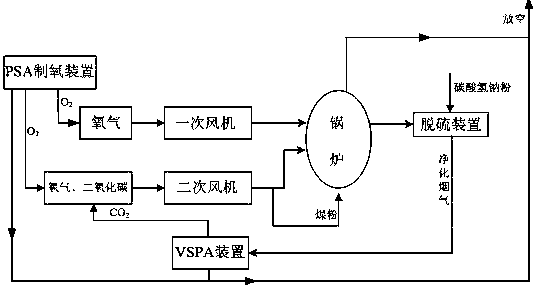

[0028] This embodiment relates to a boiler all-oxygen combustion process. Oxygen is fed into the boiler as primary air, and oxygen and carbon dioxide are fed into the boiler as secondary air. The flue gas after boiler combustion is passed through the desulfurization device to obtain purified flue gas. In the wind, the volume ratio of oxygen to carbon dioxide is controlled at 21:79.

Embodiment 2

[0030] This embodiment relates to a boiler all-oxygen combustion process. Oxygen is fed into the boiler as primary air, and oxygen and carbon dioxide are fed into the boiler as secondary air. The flue gas after boiler combustion is passed through the desulfurization device to obtain purified flue gas. In the wind, the volume ratio of oxygen to carbon dioxide is controlled at 23:77.

[0031] In this embodiment, the oxygen used in the primary air and the oxygen used in the secondary air are both produced by the PSA oxygen production device, and the exhaust air of the PSA oxygen production device and the excess carbon dioxide generated by the combustion of the boiler are vented through the chimney.

Embodiment 3

[0033] This embodiment relates to a boiler all-oxygen combustion process. Oxygen is fed into the boiler as primary air, and oxygen and carbon dioxide are fed into the boiler as secondary air. The flue gas after boiler combustion is passed through the desulfurization device to obtain purified flue gas. In the wind, the volume ratio of oxygen to carbon dioxide is controlled at 21:77.

[0034] In this embodiment, the carbon dioxide used in the secondary air is produced from the purified flue gas through the VSPA device, and the excess carbon dioxide produced by the VSPA device and the excess carbon dioxide generated by the combustion of the boiler are vented through the chimney.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com