Structural ceramic sample dielectric performance measuring device and method thereof

A technology of dielectric properties and measuring devices, which is applied in the field of measurement of dielectric properties of structural ceramic samples, can solve the problems of difficulty in sintering large products, poor uniformity of microwave field, low dielectric loss, etc., to achieve convenient observation and testing, and reduce temperature Effects of Gradients, Reduction Requirements, and Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

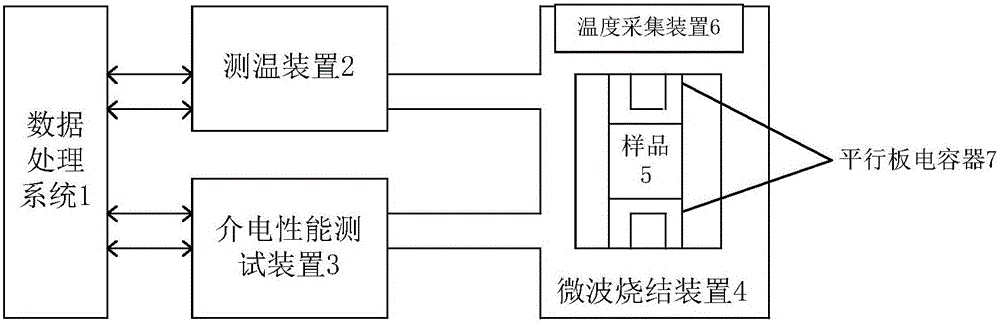

[0021] The main structure of the special ceramic sample dielectric property measuring device described in this embodiment includes a data processing system 1, a temperature measuring device 2, a dielectric property testing device 3, a microwave sintering device 4, a sample 5, a temperature acquisition device 6 and a parallel plate capacitor 7. The microwave sintering device 4 is equipped with a temperature acquisition device 6 and a sample 5. The microwave sintering device 4 controls the temperature range of the sample 5 from room temperature to 1000 degrees Celsius. The two ends of the sample 5 are provided with parallel plate capacitors 7. The diameter of the sample 7 is The size is less than 30mm; the temperature collection device 6 and the sample 5 are not in contact with each other, and the guide wires drawn from the sample 5 and the temperature collection device 6 are respectively connected to the dielectric property testing device 3 and the temperature measuring device 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com