Surface-Emitting Semiconductor Laser, Surface-Emitting Semiconductor Laser Array, Surface-Emitting Semiconductor Laser Device, Optical Transmission Device, And Information Processing Device

A semiconductor, surface emitting technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of reducing carriers, high device resistance, increasing carrier penetration, etc., and achieves the effect of reducing oxidation and easy resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

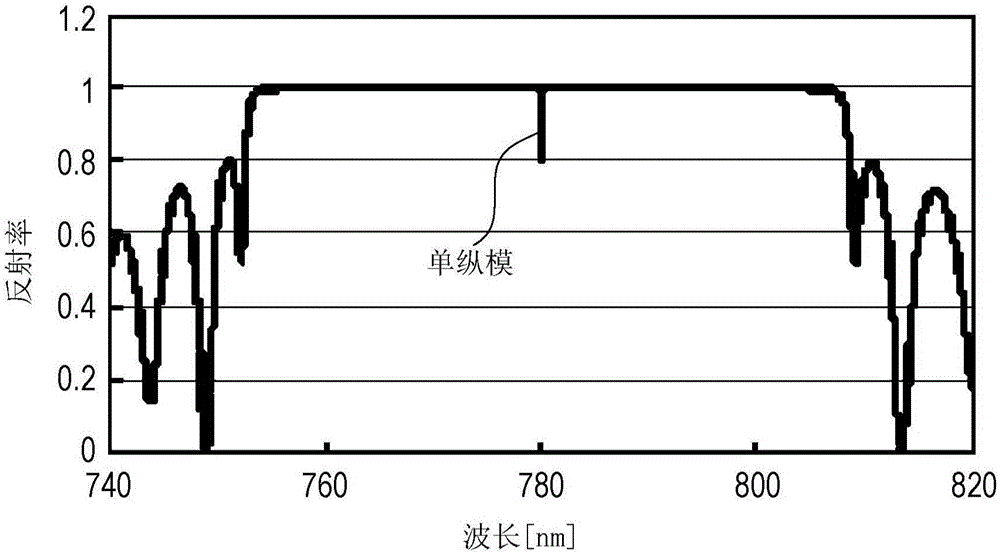

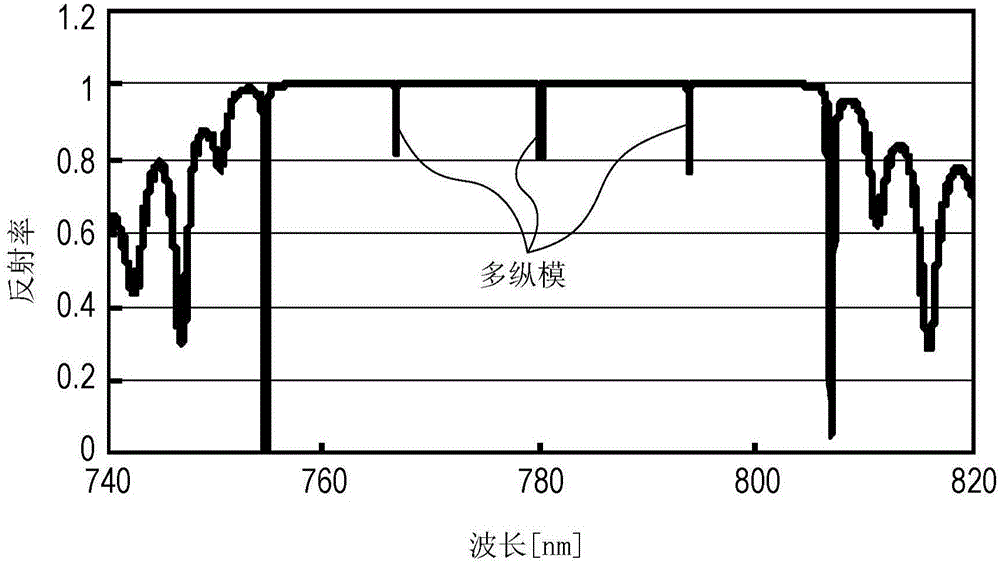

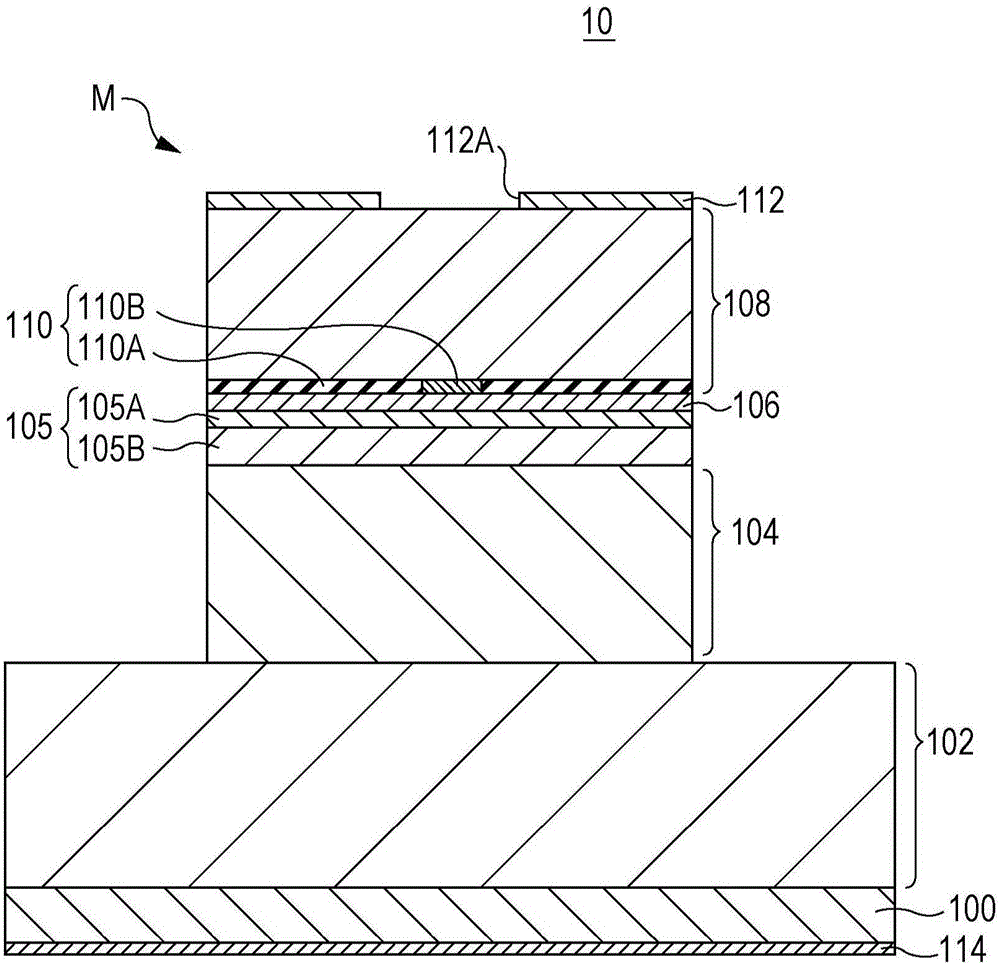

[0045] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. Surface emitting semiconductor lasers (ie, vertical cavity surface emitting lasers, hereinafter abbreviated as "VCSEL") have been used as light sources for communication devices or image forming devices. In order to further increase the printing speed in the future, there is a demand for single-mode, high light output VCSEL. In order to realize single-mode (ie, fundamental transverse mode) operation using the oxidation-constrained type structure of the related art, it is necessary to set the diameter of the oxidation orifice to be 2 to 3 μm. However, setting the diameter of the oxidation aperture to 2 to 3 μm makes it difficult to uniformly achieve a single-mode light output of 3 mW or more. Setting the diameter of the oxidation aperture larger than 2 to 3 μm enables high light output, but disadvantageously, multi-mode (ie, higher transverse mode) oscillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com