Assembling welding method of side guard plate of hydraulic support

A hydraulic support and welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency, increasing manufacturing costs, and high requirements for interchangeability of finished products, achieving low production costs and solving large deformation , the effect of design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

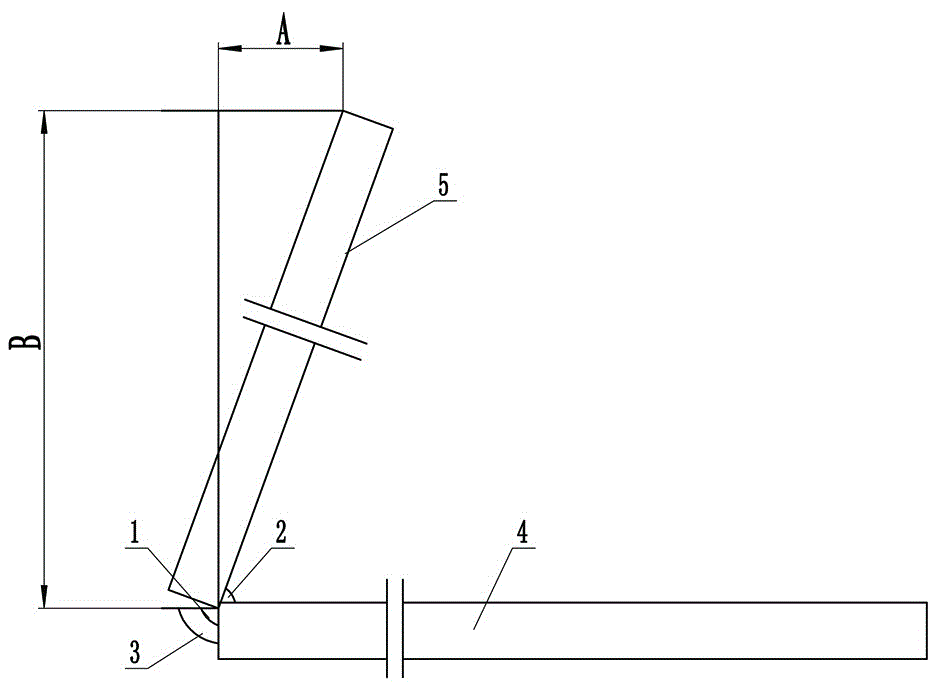

[0022] like figure 1 As shown, a method for assembling and welding hydraulic support side guards, said hydraulic support side guards include side plates 4 and top plates 5, the method can be used for the top beam side guards and shield beam side guards in the hydraulic support frame , Tail beam side guard plate, etc. are assembled and welded. The method for assembling and welding the side guard of the hydraulic support includes the following steps: Step 1. Measure the width of the top plate 5, and determine the amount of reverse deformation according to the width B. In this embodiment, the width B of the top plate 5 is 220mm , The amount of anti-deformation A is 1.5mm, welding wire ER50-6 is used for welding, and the diameter of the welding wire is Φ1.2mm.

[0023] Step 2, the bottom of the top plate 5 is in contact with the side plate 4, and the top of the top plate 5 tilts to move the reverse deformation amount A.

[0024] Step 3. Weld the first weld seam 1 along the outer...

Embodiment 2

[0037] The main difference between this embodiment and Embodiment 1 is that: the width of the top plate is different, resulting in different welding parameters. In this embodiment, the width of the top plate is 350 mm, and the anti-deformation amount A is 4 mm. When welding, welding wire ER62-G is used, and the diameter of the welding wire is Φ1.2 mm, and then assembled and welded.

[0038] When welding the first weld seam, the welding current is 280A, the welding voltage is 30V, and the welding speed is 350mm / min; the welding of the bottom welding is completed.

[0039] When welding the second weld seam, the welding current is 300A, the welding voltage is 32V, and the welding speed is 380mm / min; the filling welding is completed.

[0040] When welding the third weld seam, the welding current is 300A, the welding voltage is 32V, and the welding speed is 380mm / min; the cover welding is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com