Spiral Filter Press Trash Grille Machine

A grid machine, screw technology, applied in sludge treatment, filtration treatment, water/sewage treatment and other directions, can solve the problems of incomplete separation, poor working conditions, chain creep and other problems, achieve small daily maintenance, solid-liquid Complete separation and good effect of squeezing garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to introduce the present invention in more detail, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

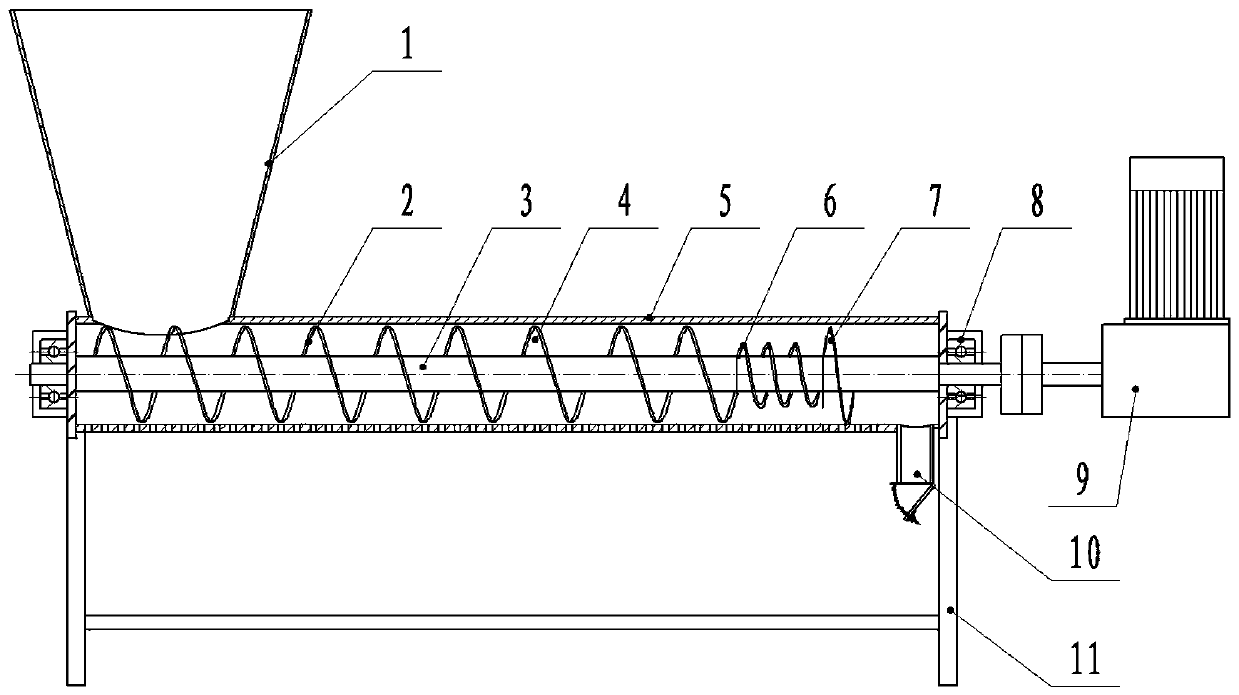

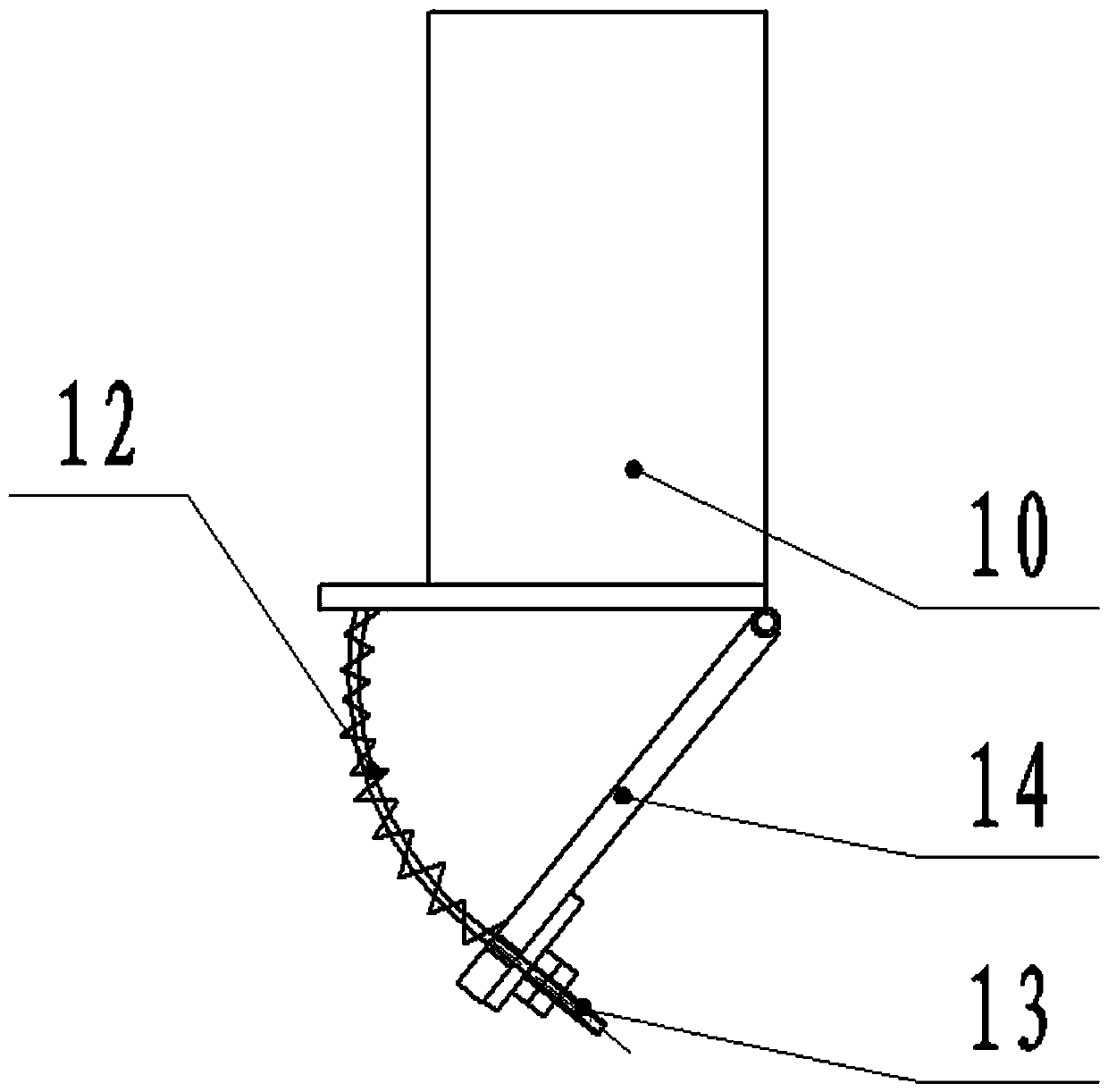

[0023] The spiral filter press trash grill machine of the present invention comprises a rotating shaft 3, a casing 5 and a frame 11, the casing 5 is installed on the frame 11, the rotating shaft 3 is installed in the casing 5 through a bearing seat 8, and the rotating shaft Driven by a geared motor 9, a feeding bin 1 is arranged above one end of the casing 5, a filter residue outlet 10 is arranged below the other end of the casing 5, and a plurality of drain holes are arranged under the casing 5, and the rotating shaft 3 starts from the feeding bin 1 end. The No. I screw blade 2, the No. II screw blade 4, the III screw blade 6 and the IV screw blade 7 are installed in sequence, the I screw blade 2, the II screw blade 4, the III screw blade 6 and the IV screw blade 7 The pitch ratio is 3:2:1:1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com