Precipitated sludge backflow coagulation aiding and re-nucleation clarifying device

A sludge return and clarification device technology, applied in flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment, etc. Complicated problems, to achieve stable and efficient treatment effects, to solve the effect of large footprint and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention is described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention.

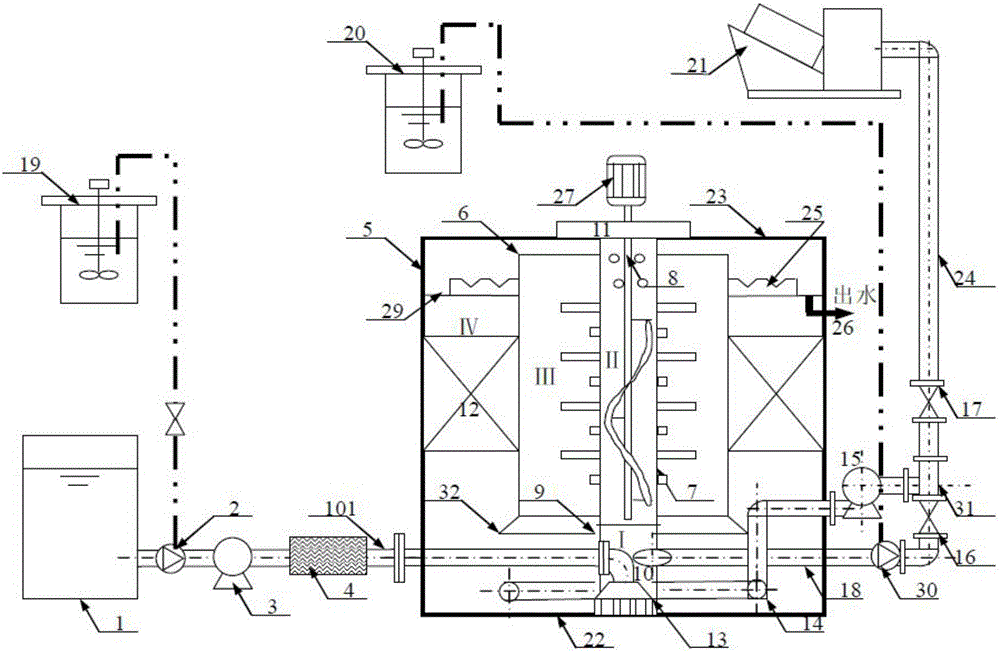

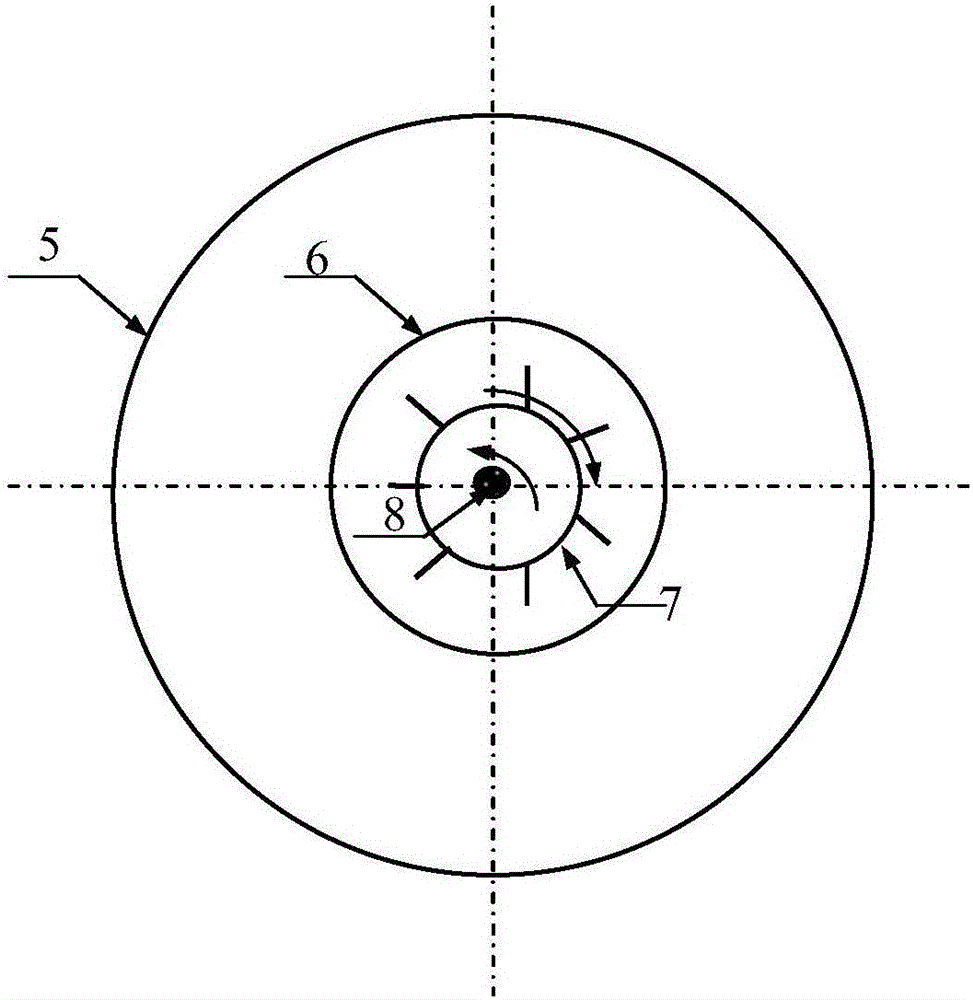

[0028] See figure 1 with figure 2 The device of the present invention includes a water inlet and outlet unit, a medicament dosing and mixing unit, a coagulation sedimentation unit and the like. The effluent in the raw water tank 1 passes through the coagulant dosing port 2, and then sequentially passes through the lift pump 3 and the pipeline mixer 4, and then enters the mixing zone I in the shell through the water inlet 13. The shell consists of a coaxial outer cylinder 5, The middle cylinder 6 and the inner cylinder 7 are composed of three layers of cylinders. The whole shell is cylindrical. The three layers of cylinders divide the space area into four parts, namely, water inlet and return flow sedimentation sludge mixing z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com