Preparation method of three-dimensional paper-based metal organic framework

An organic framework and metal-based technology, applied in the field of preparation of three-dimensional paper-based metal-organic framework, can solve the problems of complex preparation process, unfavorable detection, high cost, etc., and achieve the effect of low reaction temperature, short reaction time and easy folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a paper-based metal-organic framework with simple process and portability The specific preparation process is as follows:

[0021] (1) Selection of paper base: choose ordinary filter paper or chromatographic paper as the paper base, and cut it into A4 size paper;

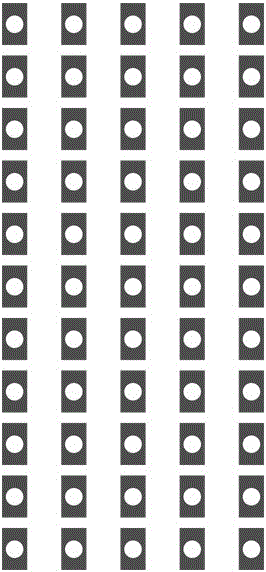

[0022] (2) Design the batch printing pattern of hydrophobic wax on the paper base on the computer, the style is as attached figure 1 shown;

[0023] (3) Use wax printing technology to print the hydrophobic wax batch printing pattern designed in step (2) on A4 paper, then take out the paper, place it in an oven, and heat it at 130~150 ºC for 2 minutes to melt the wax And soak through the entire thickness of the paper to form a hydrophobic wall, and the part without printing wax is a hydrophilic area;

[0024] (4) Growth of paper-based metal-organic frameworks:

[0025] The growth of the paper-based metal organic framework comprises the following steps:

[0026] To grow a dense layer ...

Embodiment 2

[0028] The preparation steps are the same as in Example 1, except that the deposition charge in step (5) is 0.05 C.

Embodiment 3

[0030] The preparation steps are the same as in example 1, the difference is: in step (5) CuSO 4 The solution concentration was 10.0 mM, and the deposition charge was 0.01 C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com