Highly filled white carbon black tread rubber having good electric and thermal conductivity and used for pneumatic tire

A technology of pneumatic tires and white carbon black, which is applied in the field of automobile tire materials, can solve the problems of poor electrical conductivity and thermal conductivity, and achieve the effects of preventing premature aging, improving material performance, and extending the service life of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

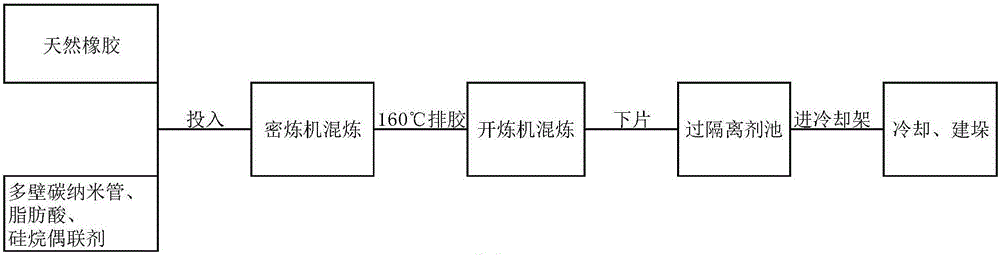

Method used

Image

Examples

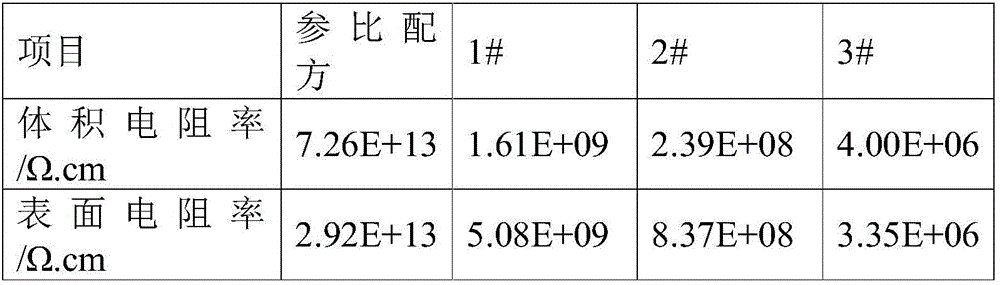

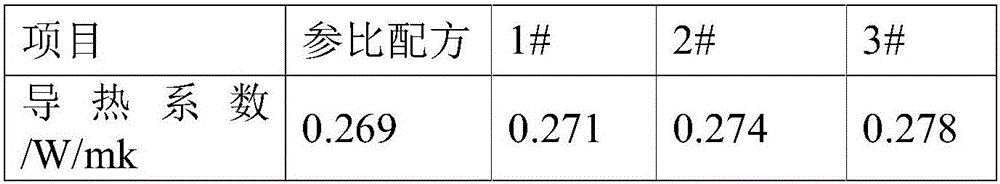

Embodiment 1

[0026] A kind of tire tread rubber with good electrical conductivity and thermal conductivity and highly filled white carbon black, is characterized in that 60 parts of the solution-polymerized styrene-butadiene rubber, 40 parts of butadiene rubber, 50 parts of white carbon black, and 5 parts of carbon black , 8 parts of silane coupling agent, 3 parts of modified conductive composite material, 3 parts of resin, 3 parts of zinc oxide, 0.5 part of stearic acid, 0.5 part of sulfur, 0.5 part of accelerator, and 4 parts of other components.

Embodiment 2

[0028] A kind of tire tread rubber with good electrical conductivity and thermal conductivity and high filling white carbon black, is characterized in that 70 parts of the solution-polymerized styrene-butadiene rubber, 30 parts of butadiene rubber, 60 parts of white carbon black, and 8 parts of carbon black , 10 parts of silane coupling agent, 8 parts of modified conductive composite material, 4 parts of resin, 3 parts of zinc oxide, 1.5 parts of stearic acid, 1.2 parts of sulfur, 1.5 parts of accelerator, and 6 parts of other components.

Embodiment 3

[0030] A kind of tire tread rubber with good electrical conductivity and thermal conductivity and highly filled white carbon black, characterized in that, 80 parts of the solution-polymerized styrene-butadiene rubber, 20 parts of butadiene rubber, 80 parts of white carbon black, and 10 parts of carbon black , 12 parts of silane coupling agent, 12 parts of modified conductive composite material, 5 parts of resin, 4 parts of zinc oxide, 2.5 parts of stearic acid, 2.5 parts of sulfur, 1.8 parts of accelerator, and 7 parts of other components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com