Aqueous grinding liquid for optical sapphire

A sapphire and grinding fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of large amount of addition, difficulty in cleaning, short service life, etc., achieve less addition of bactericide, enhanced lubricating effect, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

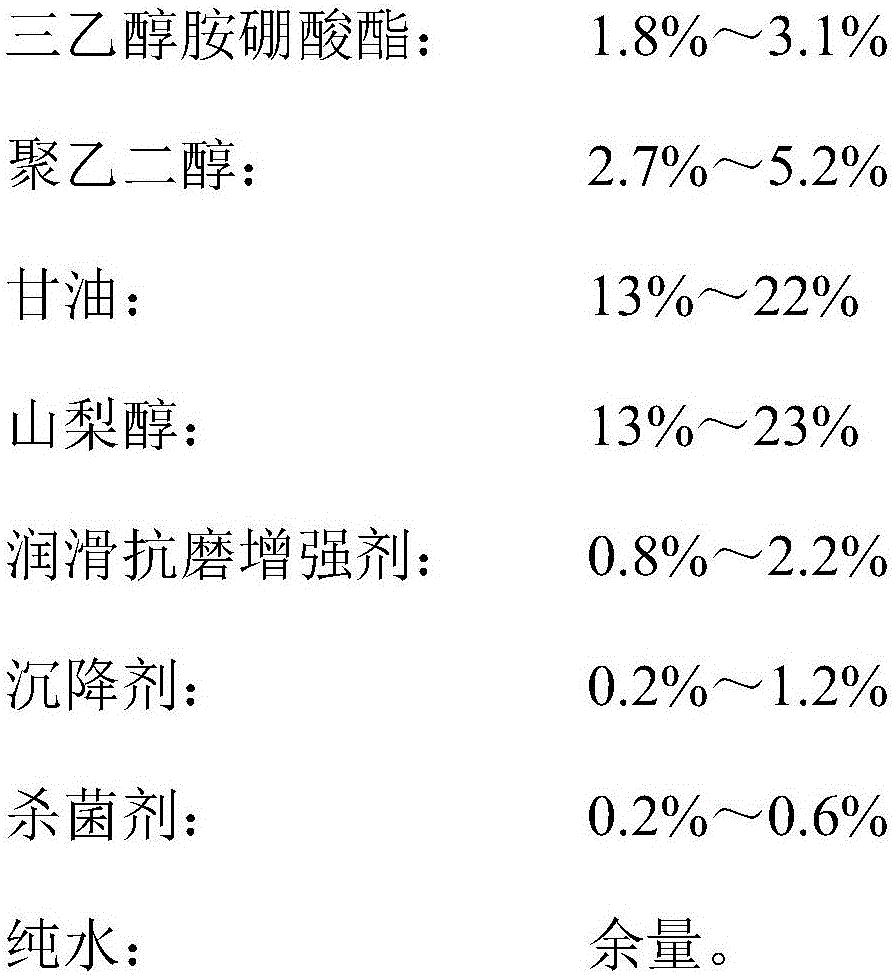

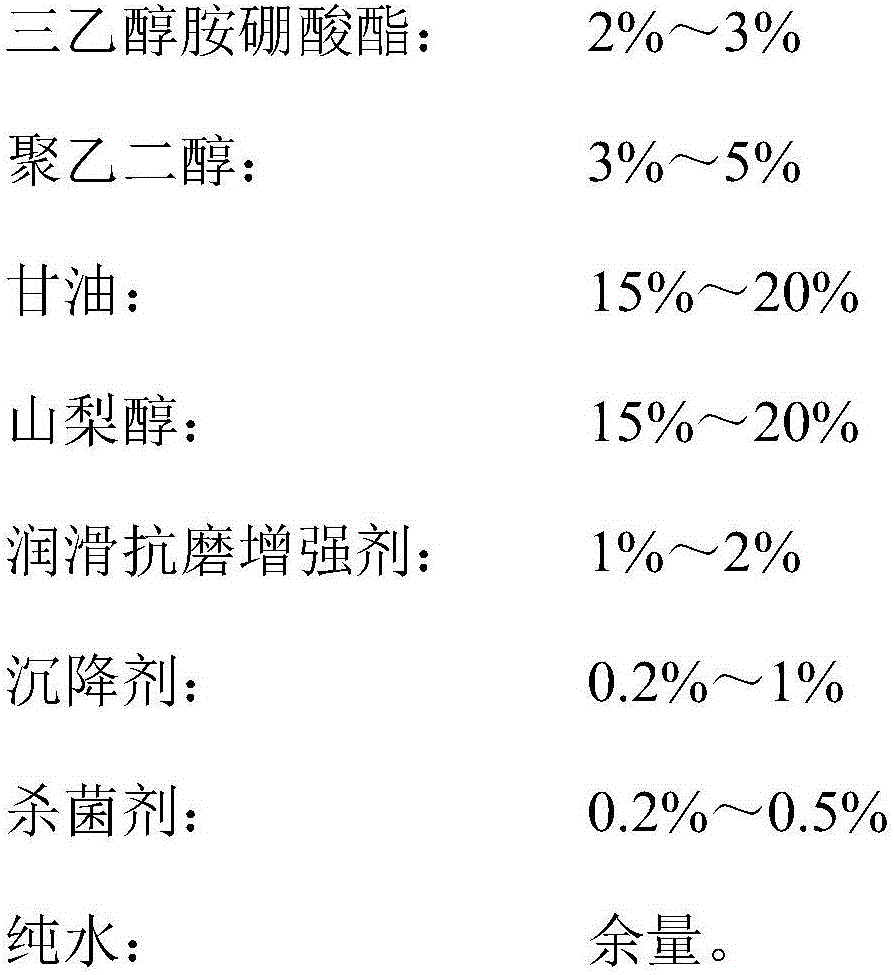

Method used

Image

Examples

Embodiment 1

[0019] Weigh 1.8kg of triethanolamine borate, 2.7kg of polyethylene glycol (600), 13kg of glycerol (glycerin), 23kg of sorbitol, 0.8kg of lubricating and antiwear enhancer, 1.2kg of sedimentation agent, 0.6kg of bactericide, Put 56.9 kg of pure water in a container and stir evenly to obtain an optical sapphire water-based grinding liquid.

[0020] In this example, the pH value of the triethanolamine borate is 8.3, and the characteristics of the triethanolamine borate are slightly alkaline, with a pH value of about 8-8.5, which can prevent rust of the equipment and does not corrode the skin of the operators. It replaces the original "sodium sulfite", which greatly reduces the risk of carcinogenesis to the skin caused by long-term use.

[0021] The polyethylene glycol described in this embodiment is polyethylene glycol 600, which uses Dow products in the United States. Its thickening performance is better than polyethylene glycol 400. Polyethylene glycol 600 has thickening and lubric...

Embodiment 2

[0029] Weigh 2kg of triethanolamine borate, 5kg of polyethylene glycol (600), 20kg of glycerol (glycerin), 15kg of sorbitol, 2kg of lubricating and antiwear enhancer, 1kg of sedimentation agent, 0.2kg of bactericide, and 54.8kg of pure water Place it in a container and stir evenly to obtain an optical sapphire water-based grinding liquid.

[0030] The characteristics of triethanolamine borate are alkalescent, with a PH value of 8.2, which can prevent the equipment from rusting and is non-corrosive to the skin of operators. It replaces the original "sodium sulfite", which greatly reduces the long-term use of Risk of carcinogenesis from the skin.

[0031] The polyethylene glycol described in this embodiment is polyethylene glycol 600, which uses Dow products in the United States. Its thickening performance is better than polyethylene glycol 400. Polyethylene glycol 600 has thickening and lubricating properties. Better sex.

[0032] The optical sapphire water-based grinding fluid of t...

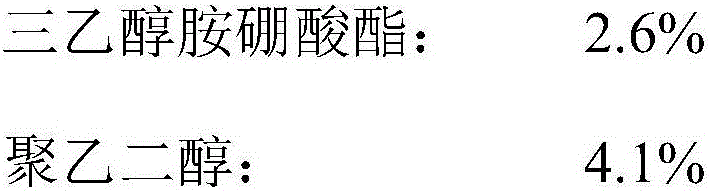

Embodiment 3

[0034] Weigh 2.6kg of triethanolamine borate, 4.1kg of polyethylene glycol (600), 17kg of glycerol (glycerin), 18kg of sorbitol, 1.6kg of lubricating and antiwear enhancer, 0.8kg of sedimentation agent, and 0.3kg of bactericide. Put 55.6 kg of pure water in a container and stir evenly to obtain an optical sapphire water-based grinding liquid.

[0035] The properties of triethanolamine borate are alkalescent, with a PH value of 8, which can prevent the equipment from rusting, and is non-corrosive to the skin of operators. It replaces the original "sodium sulfite", which greatly reduces the long-term use of Risk of carcinogenesis from the skin.

[0036] The polyethylene glycol described in this embodiment is polyethylene glycol 600, which uses Dow products in the United States. Its thickening performance is better than polyethylene glycol 400. Polyethylene glycol 600 has thickening and lubricating properties. Better sex.

[0037] The optical sapphire water-based grinding fluid of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com