A Coiled Tubing Drilling Torque Booster

A technology of increasing torque and pressure-on-bit, applied in drilling equipment, earthwork drilling, rotary drilling rigs, etc., can solve problems such as low operating torque on bit, poor adaptability to well diameter changes, discontinuous work of crawlers, etc., to achieve continuous work , Adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

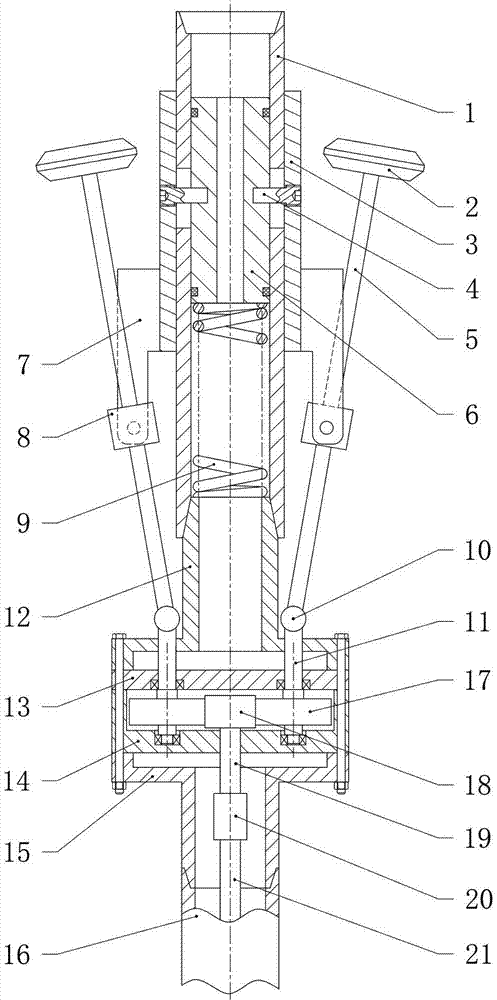

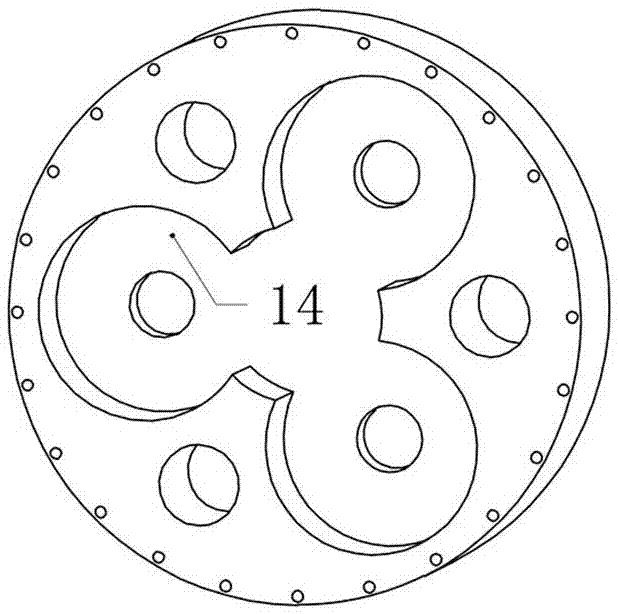

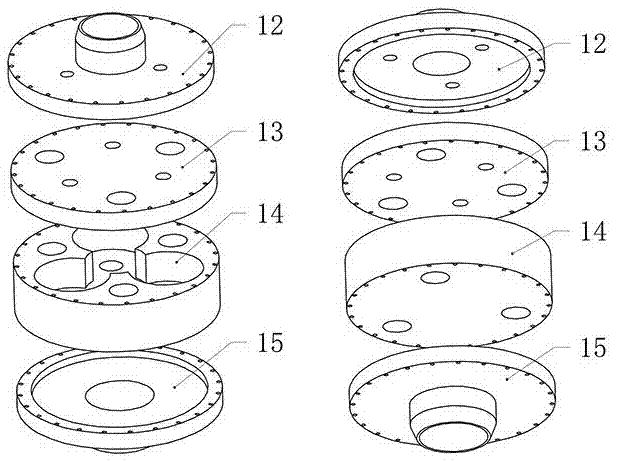

[0021] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 , image 3 , Figure 4 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0022] Coiled tubing joints or upper tools are installed on the upper end of the center barrel 1, and a transfer case is installed on the lower end of the center barrel 1 and connected with taper buckles.

[0023] A throttling cylinder 6 is set inside the central cylinder 1, and a sliding sleeve 3 is placed on the outer surface of the central cylinder 1. The central cylinder 1 is provided with an axial chute, and the screw 4 is arranged in the chute, and the throttling cylinder 6 and the sliding sleeve 3 are connected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com