Reciprocating grate biomass boiler furnace

A biomass boiler and reciprocating grate technology, applied in the boiler field, can solve the problems of increasing fuel chemical incomplete combustion loss, slow burning speed of coke particles, long drying time, etc., to solve drying problems and oxygen supply problems, and promote The effect of further complete combustion and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

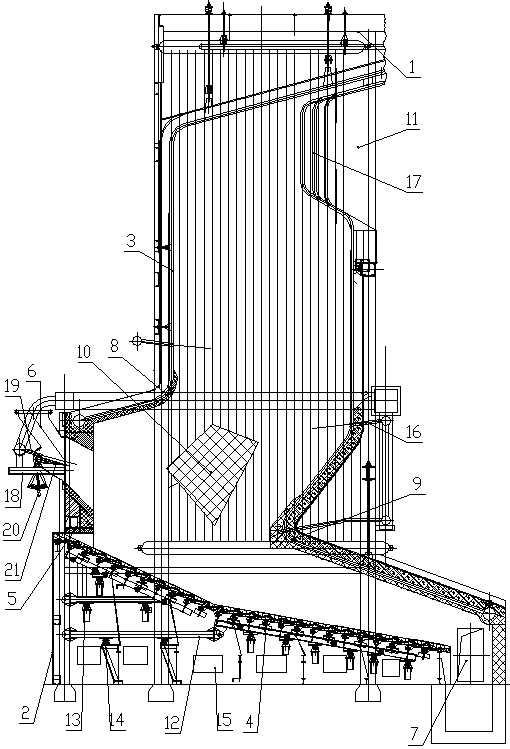

[0026] Such as figure 1 As shown, the reciprocating grate biomass boiler furnace of the present invention includes a bracket 1 and a support structure 2. A full-membrane water-cooled furnace wall 3 welded by pipes side by side is hung on the bracket 1, and small scales are arranged on the support structure 2. Fire grate 4, a sealed expansion structure 5 is provided between the lower end of the full-membrane water-cooled furnace wall 3 and the small scale fire grate 4, and a feed port 6 is provided on the front side of the lower part of the full-film water-cooled furnace wall 3, and the full-film water-cooled furnace wall A slag outlet 7 is provided between the rear side of the lower part and the small scale grate 4, and a front arch 8 and a rear arch 9 are respectively provided on the front side and the rear side of the lower part of the full-film water-cooled furnace wall 3. The small scale grate 4A two-stage or three-stage structure is adopted, and the small scale grate 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com