Fuel flow control method and system for a high-temperature burner

A technology of fuel flow and high-temperature combustion, which is applied in the direction of combustion methods, control of combustion, and adjustment of fuel supply, etc., and can solve problems such as pollution, energy waste, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

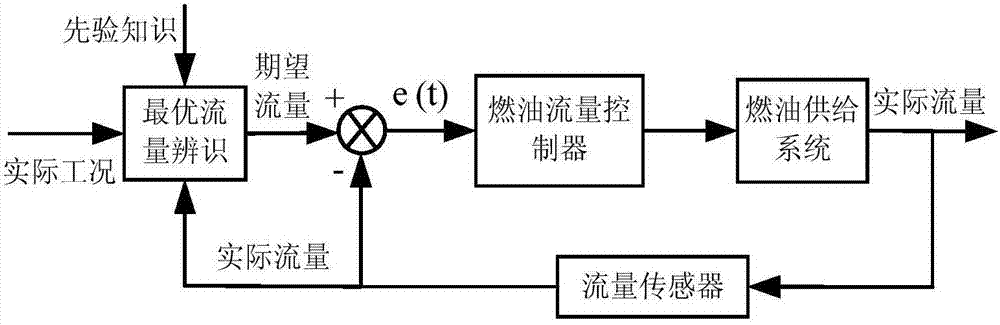

[0029] See figure 1 .

[0030] A fuel flow control method for a high-temperature burner, comprising the following steps:

[0031] S1 establishes the mathematical model of the fuel supply system, and conducts theoretical analysis on the mathematical model to obtain the basic characteristics of the fuel supply system, including fuel supply flow and pressure characteristics;

[0032] S2 analyzes the influence of the parameters of the fuel supply system on the combustion performance of the high-temperature burner, and obtains the distribution of the outlet temperature of the combustion chamber and the law of exhaust emission under various fuel supply parameters;

[0033] S3 obtains prior knowledge of the system according to the two-step analysis of steps S1 and S2;

[0034] S4 uses the system identification method to identify the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com