Anti-oxidation capacitor film and preparation method thereof

A capacitor film, anti-oxidation technology, applied in the direction of multilayer capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of capacitor breakdown accidents, poor repositioning force, etc., and achieve extended service life, smooth surface, and improved cleanliness. and the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

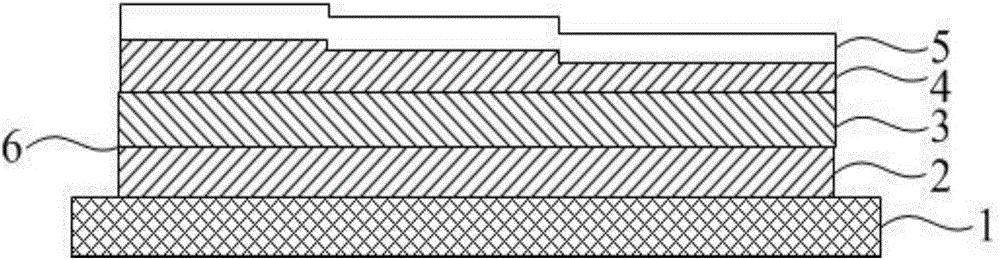

[0028] Such as figure 1 As shown, an anti-oxidation capacitor film includes a base film 1 and a first aluminum coating 2, a zinc coating 3 and a second aluminum coating 4 that are sequentially plated on the base film 1, the first aluminum coating 2 and the A blank area 6 is left at the edge of the base film 1; a layer of tung oil protective layer 5 is arranged on the second aluminum coating 4, and the tung oil protective layer 5 combines the first aluminum coating 2, the zinc coating 3 and the The second aluminum coating 4 is isolated from the air, and the second aluminum coating 4 has a stepped structure.

[0029] In this embodiment, the base film 1 is a polypropylene capacitor film.

[0030] In this embodiment, the base film 1 has a thickness of 2 μm and a width of 300 mm.

[0031] In this embodiment, the width of the blank area 6 is 1 mm.

[0032] Correspondingly, the present invention also provides a preparation method of the anti-oxidation capacitor film, comprising th...

Embodiment 2

[0046] An anti-oxidation capacitor film, comprising a base film and a first aluminum coating, a zinc coating and a second aluminum coating sequentially plated on the base film, leaving blanks at the edges of the first aluminum coating and the base film area; the second aluminum coating is provided with a layer of tung oil protective layer, and the tung oil protective layer isolates the first aluminum coating, the zinc coating and the second aluminum coating from the air, and the second aluminum coating is a ladder structure.

[0047] In this embodiment, the base film is a polypropylene capacitor film.

[0048] In this embodiment, the base film has a thickness of 2.5 μm and a width of 450 mm.

[0049] In this embodiment, the width of the blank area is 1-2 mm.

[0050] Correspondingly, the present invention also provides a preparation method of the anti-oxidation capacitor film, comprising the following steps:

[0051] S1. Preparation of base film:

[0052] S2, the vacuum pres...

Embodiment 3

[0064] An anti-oxidation capacitor film, comprising a base film and a first aluminum coating, a zinc coating and a second aluminum coating sequentially plated on the base film, leaving blanks at the edges of the first aluminum coating and the base film area; the second aluminum coating is provided with a layer of tung oil protective layer, and the tung oil protective layer isolates the first aluminum coating, the zinc coating and the second aluminum coating from the air, and the second aluminum coating is a ladder structure.

[0065] In this embodiment, the base film is a polypropylene capacitor film.

[0066] In this embodiment, the base film has a thickness of 5 μm and a width of 600 mm.

[0067] In this embodiment, the width of the blank area is 1-2mm.

[0068] Correspondingly, the present invention also provides a preparation method of the anti-oxidation capacitor film, comprising the following steps:

[0069] S1. Preparation of base film:

[0070] S2, the vacuum press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com