Personalized bone fracture plate and manufacturing method thereof

A manufacturing method and technology of bone plate, applied in the directions of additive manufacturing, outer plate, internal bone synthesis, etc., can solve the problems of weak fixation of metal plate, weaken the connection strength of titanium plate, prolong bone operation time, etc., and reduce medical costs. , the effect of eliminating defects and alleviating the effect of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

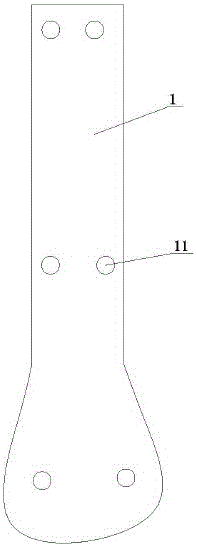

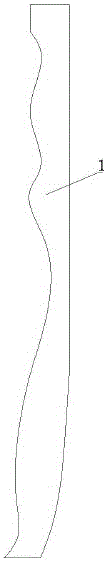

[0023] Such as figure 1 and figure 2 As shown, the personalized bone plate 1 is formed by 3D printing using magnesium alloy, and the surface of the bone plate 1 in contact with the patient's bone forms a concave-convex surface or a curved surface, so that the bone plate 1 is in contact with the shape of the patient's bone. The bone plate 1 has more than two fixing holes 11 for fixing the bone plate 1 to the patient's bone. The thickness of the bone plate is 0.5-4 millimeters, and its thickness is determined according to the needs of patients.

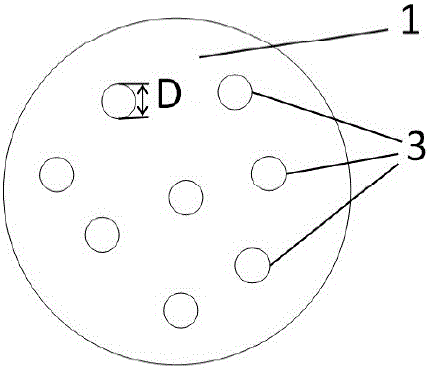

[0024] Such as image 3 As shown, a plurality of micropores and depressions 3 are distributed in the surface layer of the bone plate 1 in contact with the patient's bone. The diameter of the pores and depressions 3 is D.

[0025] The manufacturing method steps of individualized bone plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com