Rapid neutralizer for atomizing and spraying titaniferous solution in mica coating operation

An atomization spraying and coating technology, applied in the direction of chemical instruments and methods, chemical/physical/physical chemical fixed reactors, detailed information of chemical/physical/physical chemical reactors, etc., to increase neutralization speed, Effects that improve blending and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

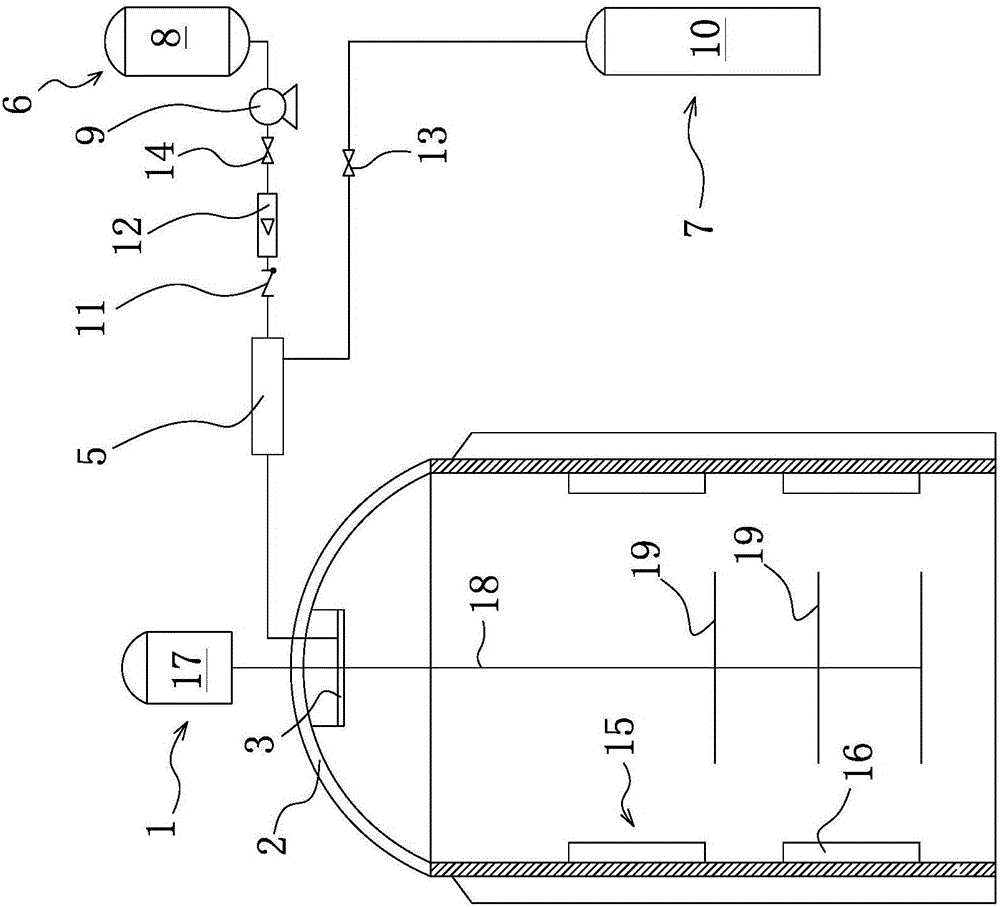

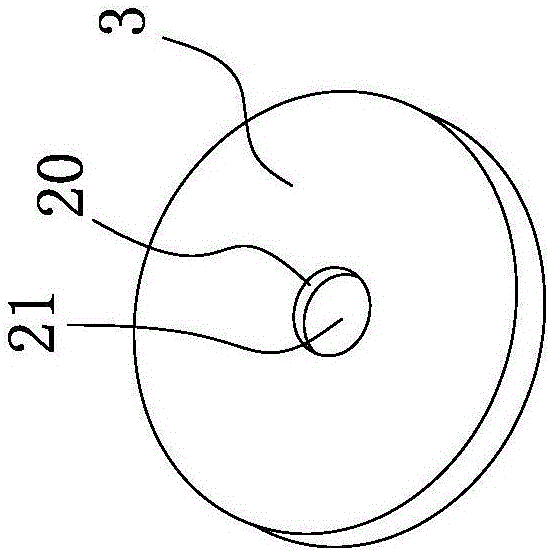

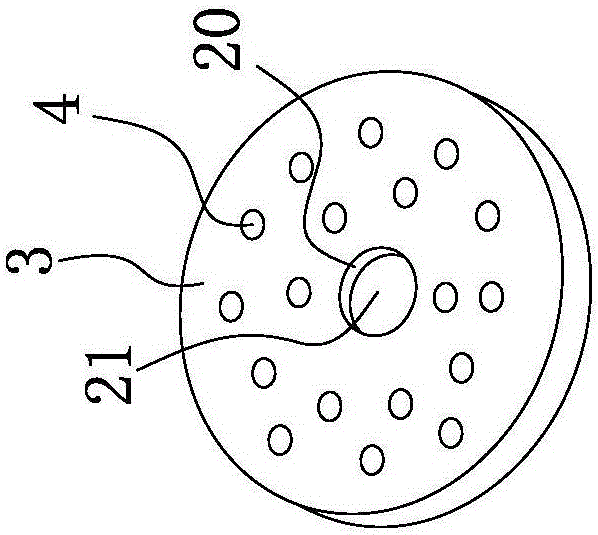

[0024] Such as figure 1 and image 3 As shown, a mica-coated titanium liquid atomization and spraying rapid neutralizer includes a reaction kettle 2 with a stirring mechanism 1, a spray plate 3 is fixed at the bottom of the reaction kettle 2, and the spray The lower surface of the plate 3 is densely covered with spray holes 4, the spray plate 3 is connected to the gas-liquid mixer 5 and the gas-liquid mixer 5 is located outside the reaction kettle 2, and the gas-liquid mixer 5 is also respectively connected to the liquid feed assembly 6 and the gas feed Component7.

[0025] Using TiCl 4 When the solution is used to modify and coat mica, it is necessary to add HCl solution and NaOH solution to adjust the pH value, so as to stabilize the pH during the coating process, so as to achieve the uniformity of coating. When adjusting the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com