Novel industrial wastewater treatment process

A technology for industrial wastewater and wastewater treatment, applied in special compound water treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of unsatisfactory treatment effect, unfavorable microbial absolute anaerobic environment, and high treatment cost question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

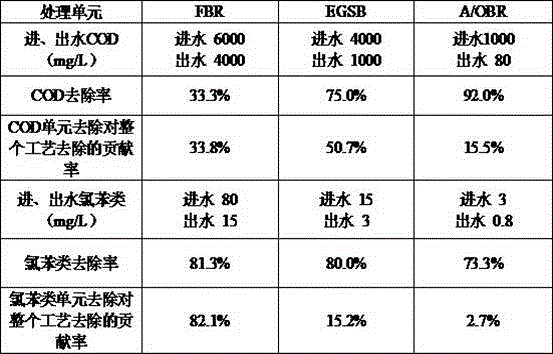

[0044] The comprehensive wastewater produced by a chemical company needs to be treated. The influent concentration before treatment is COD≤6000mg / L, pH 6.5~8.5, SS≤300mg / L, NH 3 -N≤100mg / L, TP≤2.5mg / L, characteristic pollutant concentration chlorobenzenes≤80mg / L. The effluent is required to meet the secondary standard of "Jiangsu Provincial Chemical Industry Discharge Standards for Major Water Pollutants" (DB32 / 939-2006). The effluent indicators require COD≤120mg / L, pH 6.5~8.5, SS≤150mg / L, NH 3 -N≤25mg / L, TP≤1.0mg / L, characteristic pollutant concentration chlorobenzenes≤1.0 mg / L.

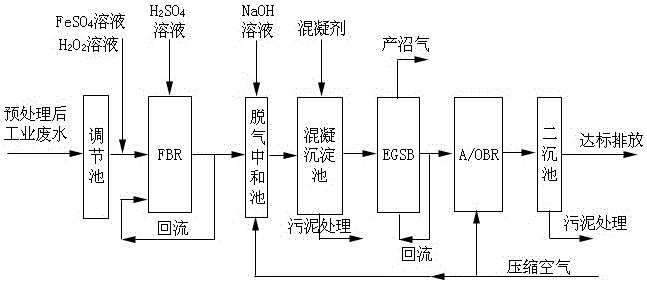

[0045] Attached figure 1 The combined process in the process uses Fenton fluidized bed (FBR), anaerobic expanded granular bed (EGSB) and anaerobic / aerobic baffle reactor (A / OBR) to treat chemical wastewater; including regulating tank, Fenton fluidized bed, degassing neutralization tank, coagulation sedimentation tank, anaerobic expanded particle bed, anaerobic / aerobic baffle reactor, connected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com