Application of hyper-branched polymer in improvement on cohesiveness of modified asphalt in water permeable asphalt pavement

A technology of tackifying resin and polyamide ester, which is applied in the direction of building structure, building components, building insulation materials, etc., and can solve problems such as poor bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

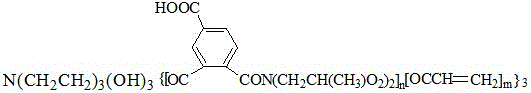

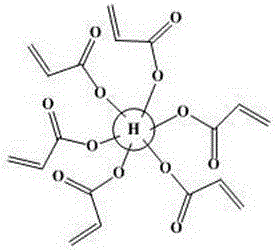

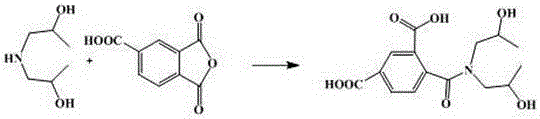

[0034] 1. Preparation of hyperbranched polymers.

[0035] (1) Weigh 8.646g of trimellitic anhydride and 5.994g of diisopropanolamine, first dissolve diisopropanolamine in 40mL of DMAc, dissolve it and pour it into a three-necked flask, then dissolve trimellitic anhydride with 40ml of DMAc, and then slowly drop it into three In the bottle, react at room temperature for 3h under stirring to obtain AB 2 type monomer.

[0036] (2) Then add 30mL toluene to the three-necked flask first, and then add 0.746 triethanolamine as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of type monomer is 1:9), then add 0.054g p-toluenesulfonic acid, heat to 130°C to condense and reflux for 24 hours, separate the generated water with a water separator, and finally purify by vacuum distillation. This product is the second Substitute hydroxyl-terminated hyperbranched polymers; (before the second step of reaction, inject toluene into the water separator to the return port).

[0037]...

Embodiment approach 2

[0043] 1. Preparation of hyperbranched polymers.

[0044] (1) Weigh 20.174g of trimellitic anhydride and 13.985g of diisopropanolamine, first dissolve diisopropanolamine in 60mL of DMAc, dissolve it and pour it into a three-necked flask, then dissolve trimellitic anhydride in 60ml of DMAc, and then slowly drop it into three In the bottle, react at room temperature for 3h under stirring to obtain AB 2 type monomer.

[0045] (2) Then add 70mL toluene to the three-necked flask first, and then add 0.746 triethanolamine as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of type monomer is 1:21), then add 0.163g p-toluenesulfonic acid, heat to 130°C, condense and reflux for 24h, separate the generated water with a water separator, and finally purify it by distillation under reduced pressure. This product is the third Substitute hydroxyl-terminated hyperbranched polymers; (before the second step of reaction, inject toluene into the water separator to the return port...

Embodiment approach 3

[0052] 1. Preparation of hyperbranched polymers.

[0053] (1) Weigh 43.229g of trimellitic anhydride and 29.968g of diisopropanolamine, first dissolve diisopropanolamine in 80mL of DMAc, dissolve it and pour it into a three-necked flask, then dissolve trimellitic anhydride in 80ml of DMAc, and then slowly drop it into three In the bottle, react at room temperature for 3h under stirring to obtain AB 2 type monomer.

[0054] (2) Then add 150mL toluene to the three-necked flask first, and then add 0.746 triethanolamine as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of type monomer is 1:45), then add 0.352g p-toluenesulfonic acid, heat to 130°C, condense and reflux for 24h, separate the generated water with a water separator, and finally purify by vacuum distillation. This product is the fourth Substitute hydroxyl-terminated hyperbranched polymers; (before the second step of reaction, inject toluene into the water separator to the return port).

[0055] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com