A chemically foamed high-density polyethylene/polypropylene composition and its preparation method

A technology of high-density polyethylene and polypropylene composition, applied in the field of foam materials, can solve the problems of rigid low-temperature performance, rigid low-temperature performance, and high wire hardness, achieve low twist breakage rate, improve compatibility, melt high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

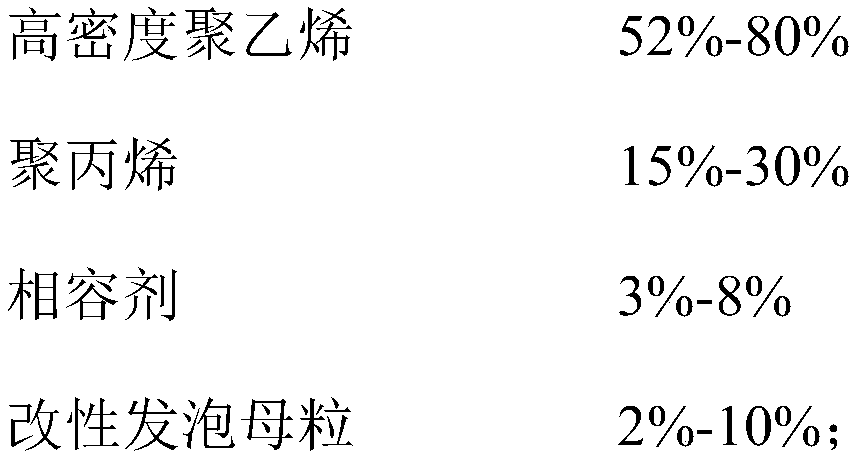

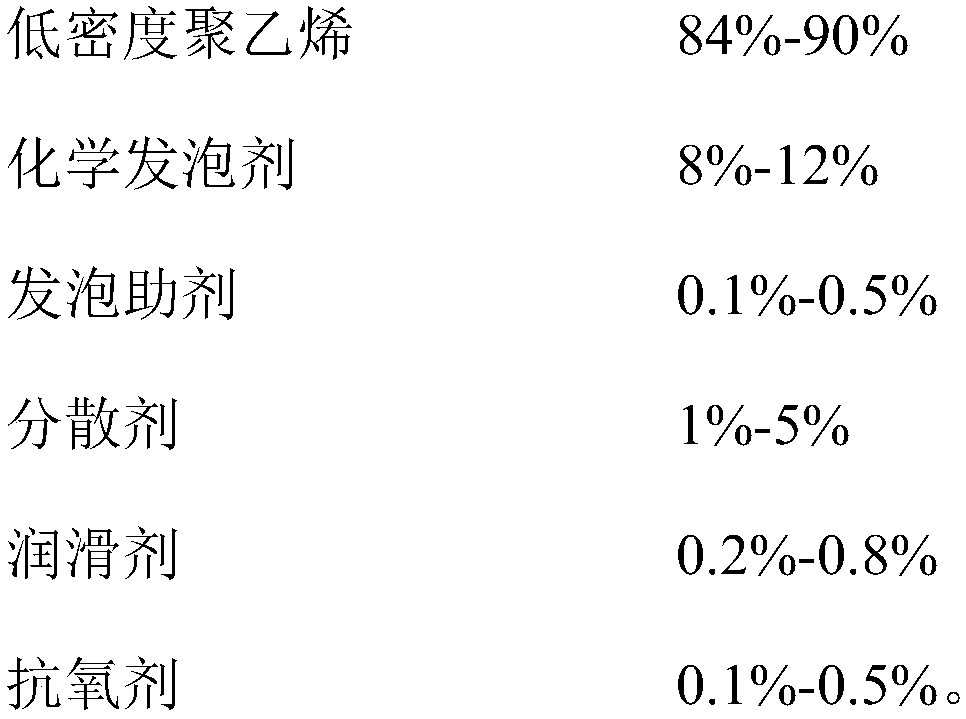

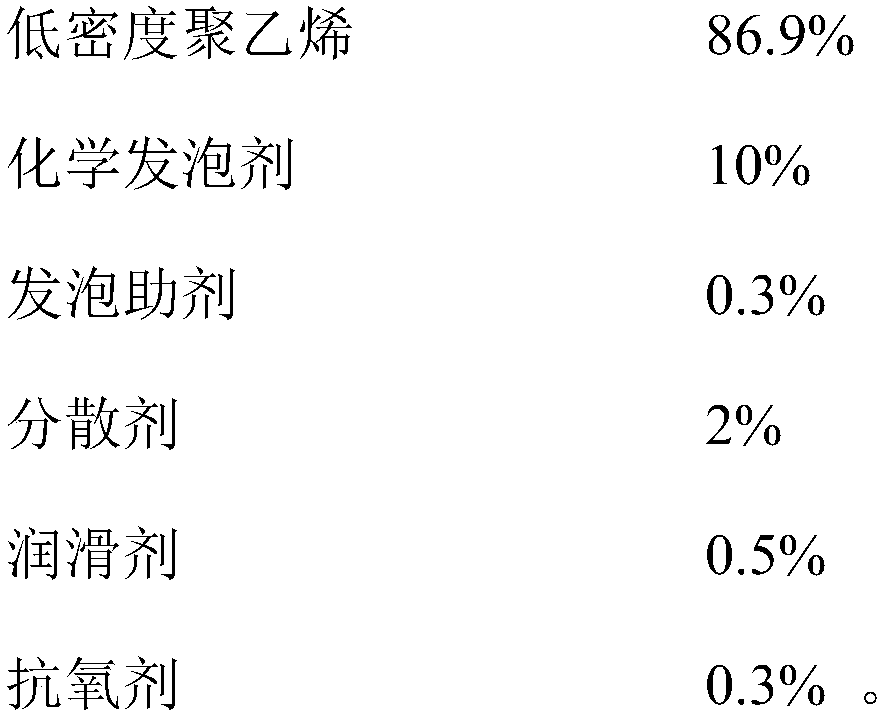

Method used

Image

Examples

Embodiment Construction

[0034] In the following specific embodiments, the high-density polyethylene (HDPE) is selected as the high-density polyethylene of DGDK-3364NT produced by Dow Chemical, and the polypropylene (PP) is selected from the polypropylene of B-PP3010 produced by Taiwan Plastics Corporation. , the compatibilizer is selected from Dow Chemical’s model as INTUNE propylene-ethylene block copolymer, the low-density polyethylene is selected from Dow Chemical’s model as DFDA-1253NT low-density polyethylene, and the chemical blowing agent is selected from Jiangsu Thorpe ADC DN-4 foaming powder produced by Fine Chemical Company, the foaming aid is zinc stearate produced by Faji (Chemical) Zhangjiagang Co., Ltd., the dispersant is Evonik Degussa Sipernat D10, and the lubricant is produced by Mitsui Chemicals The model is 30050B polyethylene wax, and the antioxidant is 1010 antioxidant produced by BASF.

[0035] The preparation method of the chemically foamed high-density polyethylene / polypropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com