Biologically-synthesized resin capable of controlling interfacial compatibility and application thereof

A technology for synthetic resin and interface control, which is applied to biosynthetic resins with controllable interface compatibility and their application fields, can solve the problem that the resin is difficult to penetrate and wet the inside of the pores, increase the difficulty of forming a good bonding force, and is difficult to form Wetting and interfacial bonding, etc., to achieve the effect of reducing interfacial incompatibility, good wetting and interfacial bonding, and reducing internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

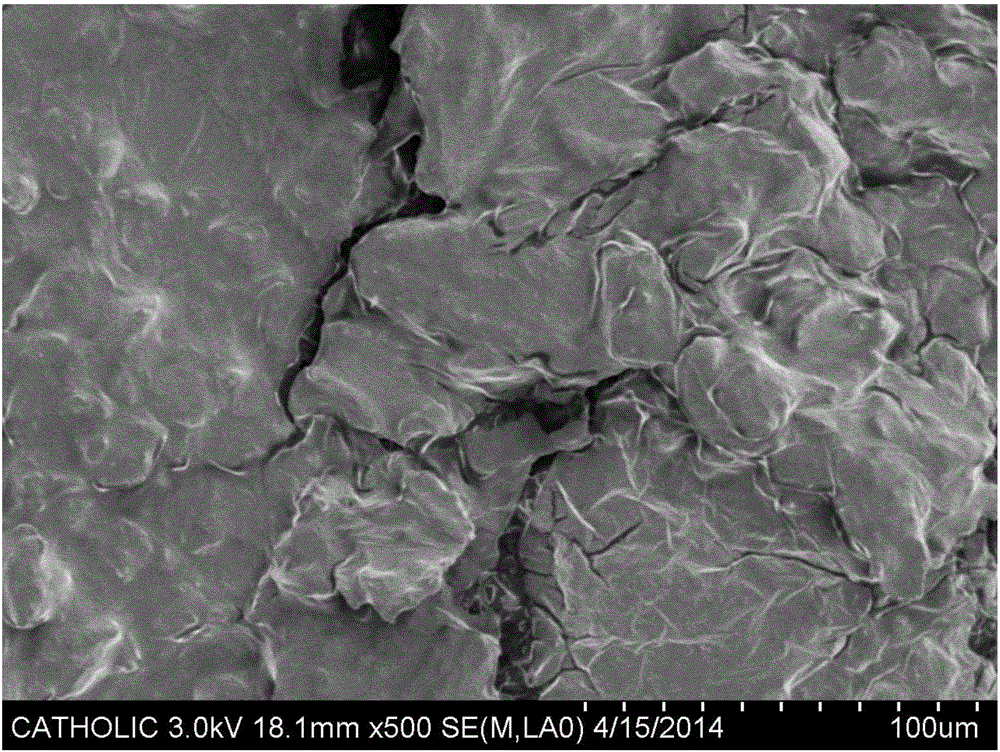

[0043] Specific embodiment 1: A biosynthetic resin with controllable interfacial compatibility of this embodiment, it is composed of resin with a mass percentage of 30-50%, and a compatibilizer with a mass percentage of 0.5-5% , a mass percentage composition of 0.5 to 3% lubricant, a mass percentage content of 0.5 to 3% oxidant and a balance of fillers; the filler is made of inorganic fillers and biomass fillers (wherein common inorganic fillers and The proportion of the biomass filler can be adjusted arbitrarily), the preparation method of the biomass filler is as follows: firstly, the biomass is dried to make its water content controlled at 2-3%, and the biomass is added into the high mixer The micropowder, coating agent and nanoparticles are blended under the condition of 80-110°C to obtain biomass filler; wherein, the mass ratio of biomass micropowder, coating agent and nanoparticle is 1:0.005~0.02:0.005~ 0.02.

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment is different from Embodiment 1 in that: the resin is a hydrophobic resin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment is different from Embodiment 1 in that: the resin is general-purpose resin such as PE, PP, PET, PVC, and PS. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com