Environment-friendly aromatic hydrocarbon rubber filling oil and production method

A technology of rubber filler oil and production method, which is applied in the refining hydrocarbon oil, petroleum industry and other directions, can solve the problems of harsh indicators, low product yield, low polycyclic aromatic hydrocarbon solubility selectivity, etc., and achieves stable performance, high product quality, The effect of uniform distribution of carbon structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

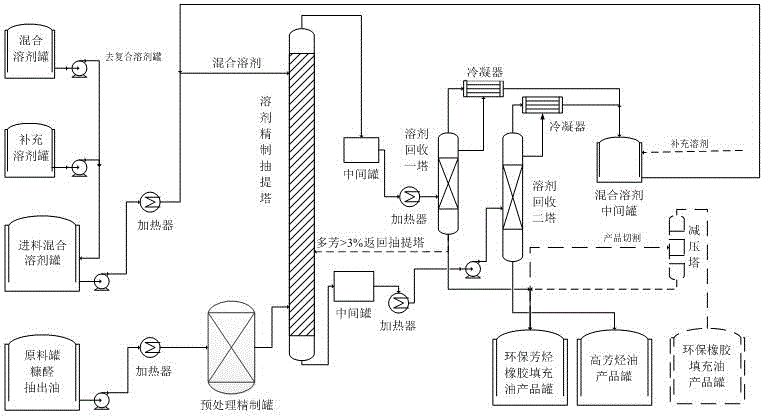

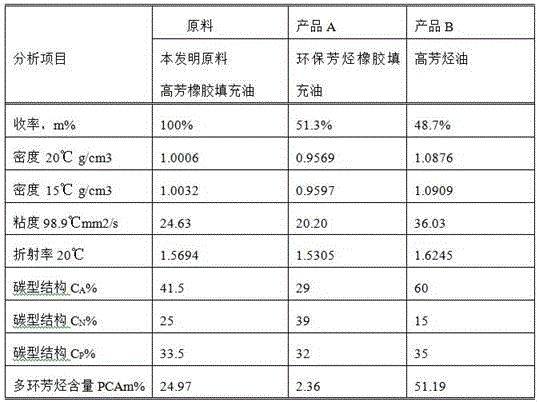

[0036] Such as figure 1 As shown, a production method of environmentally friendly aromatic rubber extender oil, using multi-component mixed solvent as the extraction agent, adopts a multi-stage extraction process for extraction, the extraction agent is input from the upper part of the extraction tower, the raw material oil is input from the lower part of the extraction tower, and the extraction agent Countercurrent contact with the raw material oil in the extraction tower, the effluent from the top of the extraction tower is a refined liquid, and the solvent is recovered through evaporation and gas stripping to obtain an environmentally friendly aromatic hydrocarbon rubber filler oil. The extract from the bottom of the extraction tower is evaporated and stripped to recover the solvent for recycling. those skilled in the art figure 1 The present invention can also be implemented after the shown process flow is changed or adjusted. Such as figure 1 As shown, the annual produc...

Embodiment 2

[0041] The multi-component mixed solvent is a mixture of N-methylpyrrolidone: polyol: sulfolane with a volume ratio of 1: (0-1): (0-1), wherein the content of the second component and the third component is not 0 at the same time. The extraction process described is a continuous extraction process, and the process conditions are: temperature 95°C, agent-oil mass ratio (2-5): 1, and time 50-80 minutes; the rest are the same as in Example 1, and the raw material oil is high aromatic oil (other Polycyclic aromatic hydrocarbons PCA = 62%); the yield of environmentally friendly aromatic rubber filler oil is 19.3%, and its polycyclic aromatic hydrocarbons PCA is 0.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com