Analysis and detection method for high purity indium

A detection method and high-purity technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the problems of low impurity content, inability to separate the matrix impurity analysis and detection, etc., to reduce the residual amount and the detection speed. Fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

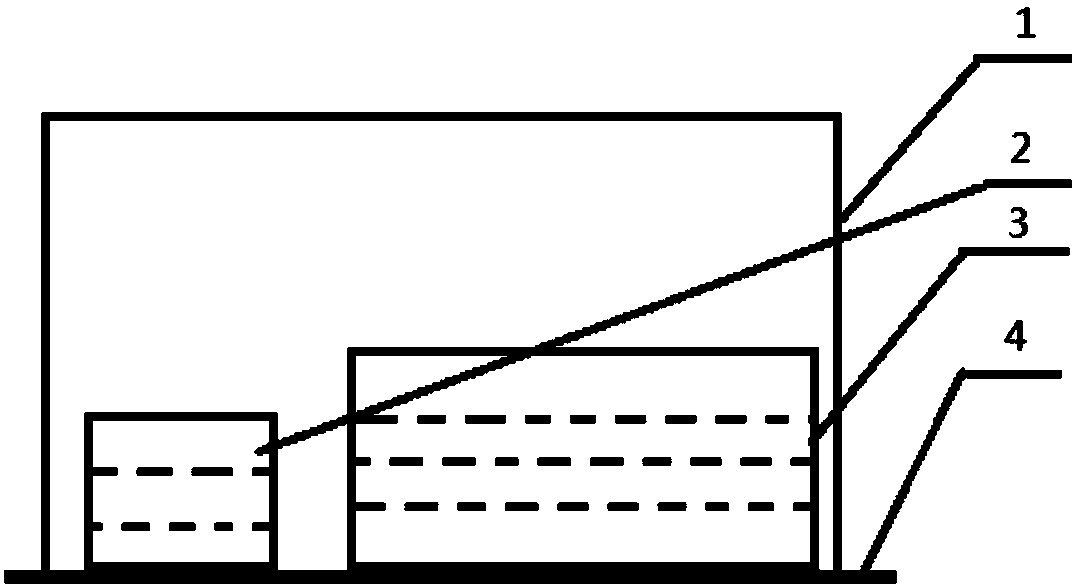

[0035] 1) Purification of ammonia water by diffusion method, the schematic diagram of the free diffusion device is as follows figure 1 shown.

[0036] On a clean polytetrafluoroethylene plate with grooves all around, fill the ammonia water to be purified with a large polytetrafluoroethylene beaker cup, and place a polytetrafluoroethylene beaker filled with pure water at the adjacent position, Cover the PTFE sealing cover, place the lower edge of the PTFE sealing cover in the groove of a clean PTFE sheet with grooves around it, fill the groove with a small amount of pure water to seal, and wait for a certain period of time ( Usually 1 week), put the ammonia water in the Teflon beaker into a clean Teflon bottle for later use.

[0037] ICP-MS detection of ammonia quality:

[0038] Table 1 Comparison of impurity content before and after ammonia water purification

[0039]

[0040]

[0041]

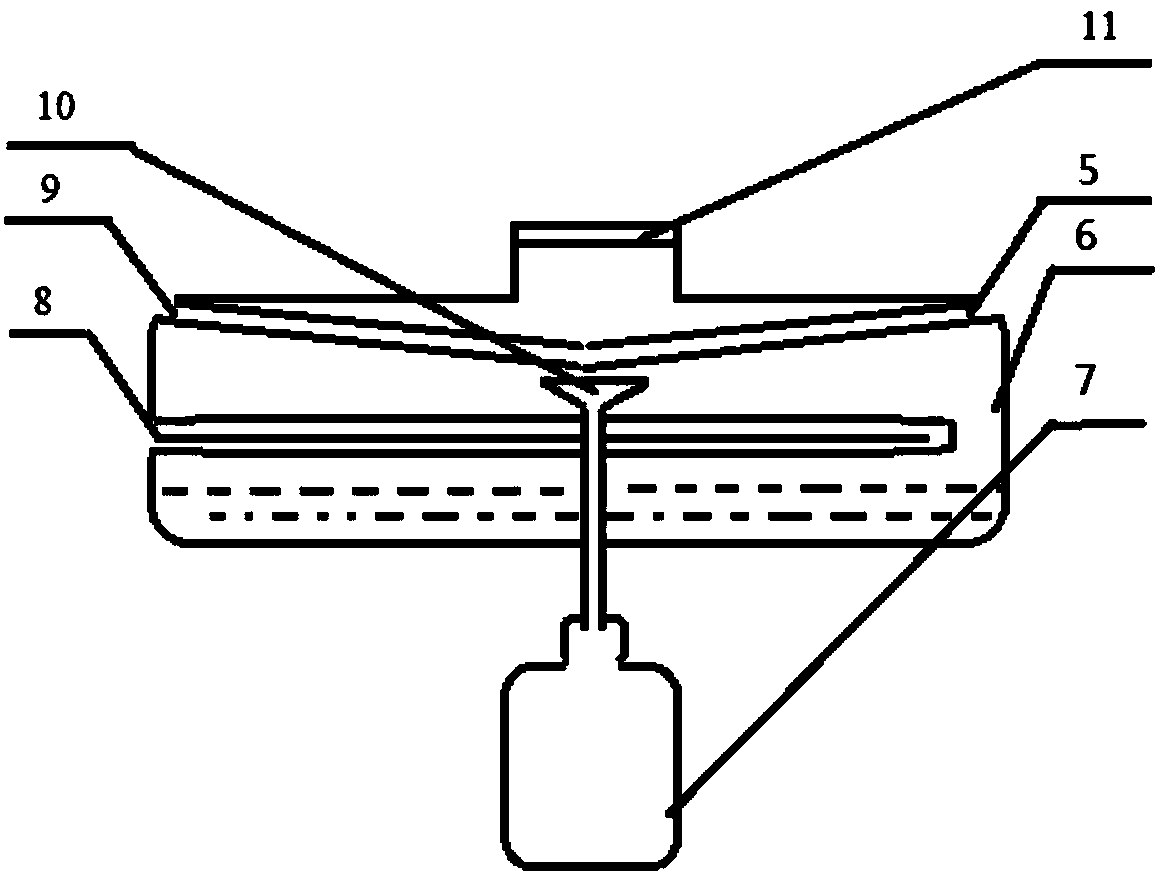

[0042] 2) Nitric acid is purified by sub-boiling distillation, and the schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com