Double stator double salient pole compound excitation motor drive system and its control method

A motor drive system and compound excitation technology, applied in the fields of motors, electrical engineering, and power electronics, can solve the problems of reliability and magnetic adjustment ability cannot be taken into account, achieve easy demagnetization, increase magnetomotive force, improve torque density and The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

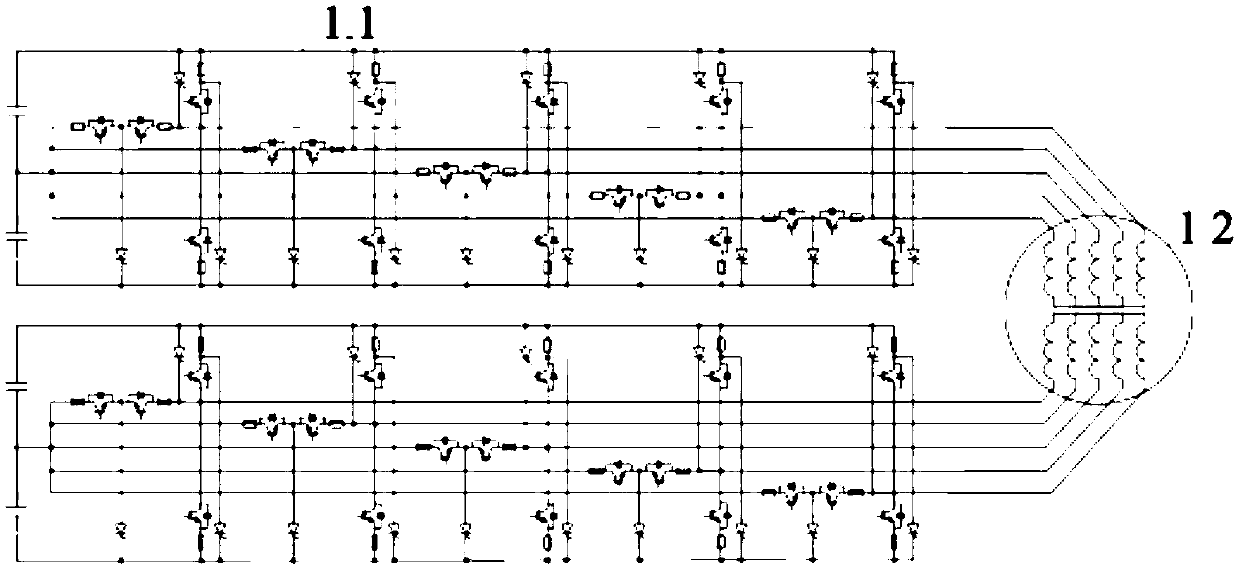

[0042] The schematic diagram of the multi-port motor drive system based on double-stator double-salient pole compound excitation motor is shown in Fig. figure 1 shown. The two fault reconstruction three-phase T-type three-level inverters 11 are respectively powered by two mutually independent DC power sources,

[0043] The double stator double salient pole motor 12 is controlled. In case of failure of one fault reconfigurable three-phase T-type three-level inverter, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com