Floating quick-change end effector for deburring

An end-operator, quick-change technology, applied in tool holder accessories, manufacturing tools, chucks, etc., can solve the problems of complex structure, large limitations and high cost, and achieve small size, improved applicability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] The main technical parameters of this embodiment are:

[0035]

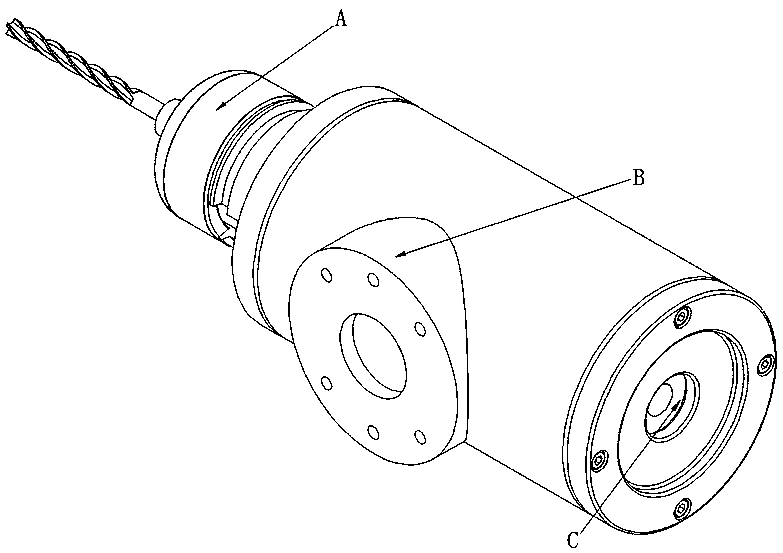

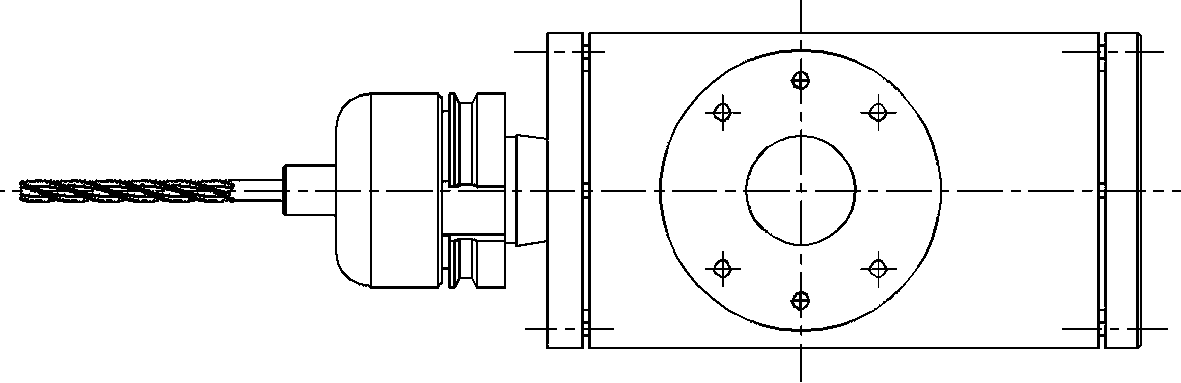

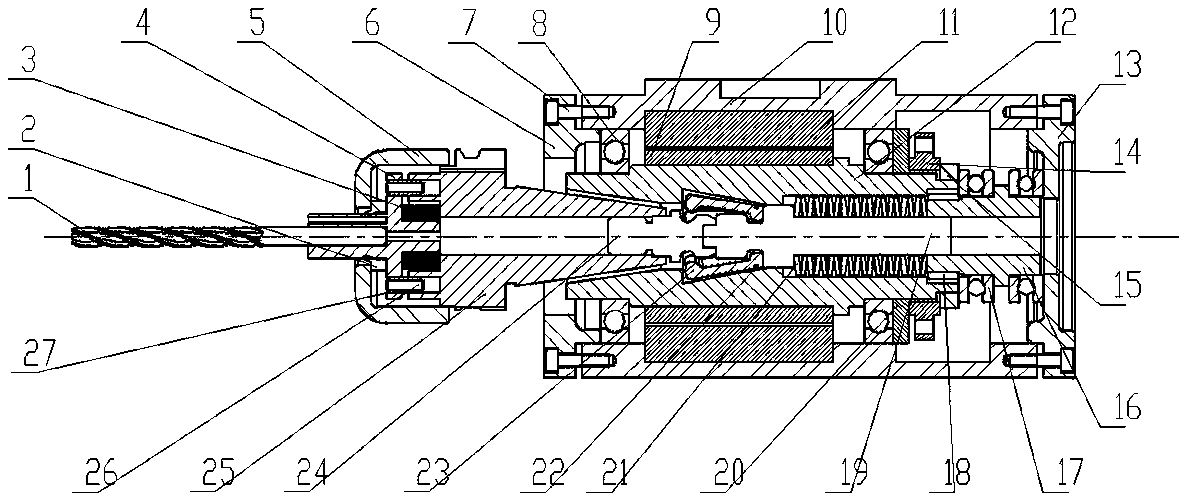

[0036] like Figure 1 to Figure 5 As shown, a floating quick-change end effector suitable for deburring includes a floating cutting module A, a spindle module B and a tool quick-changing module C; the floating cutting module A includes a tool 1, a chuck 4, an end cover 5 and Knife handle 25, one end of end cover 5 is connected and fixed with knife handle 25, the front end of chuck 4 passes through the other end of end cover 5, and the rear end is located inside end cover 5, cutting tool 1 is fixed on the front end of chuck 4, chuck 4 is connected with the handle of a knife 25 are connected by a power transmission pin 26 covered with an elastic sleeve 27, and the rear end of the collet 4 is covered with a dust-proof ring 2 and a first disc spring 3 (in this embodiment, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com