Method for extracting tetrahydro-2-ethylanthraquinone from working solution for producing hydrogen peroxide with anthraquinone method

A technology of ethyl anthraquinone and hydrogen peroxide, applied in quinone separation/purification, organic chemistry, etc., can solve the problems of increased cost, time, and cumbersome steps, and achieve the effects of improved hydrogenation efficiency, low cost, and simple and efficient extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

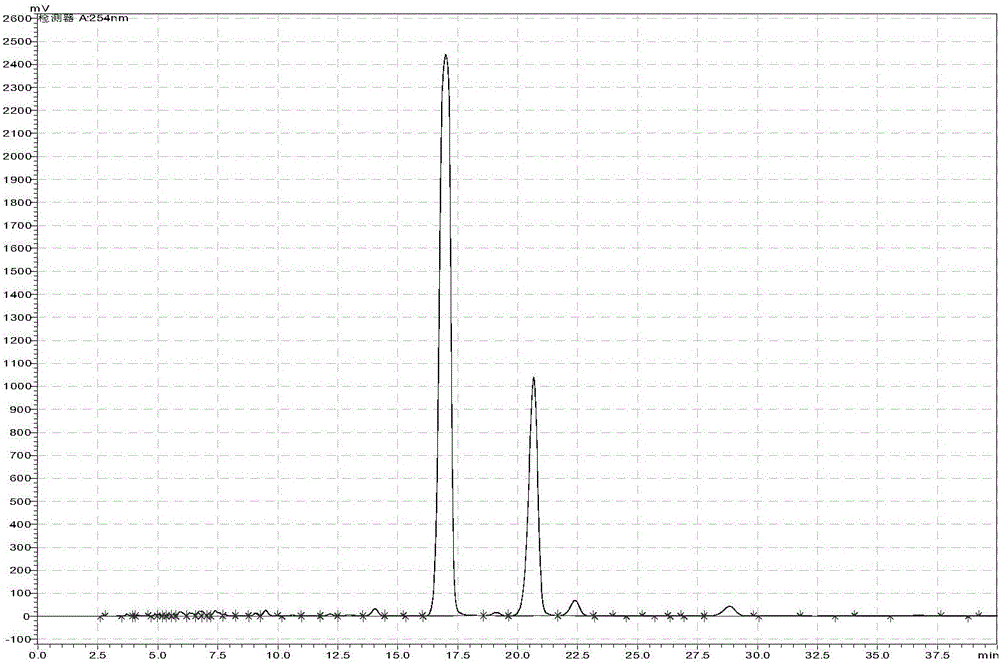

[0028] Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.1MPa, 110°C for 2h, put the residual liquid in an oven at 110°C, and cool it down to 15°C after 1.5h, at this time, a large number of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 60°C. The obtained crystals were placed in a Buchner funnel with filter paper, and heavy aromatic hydrocarbons were added dropwise at -0.1 MPa until the needle crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

Embodiment 2

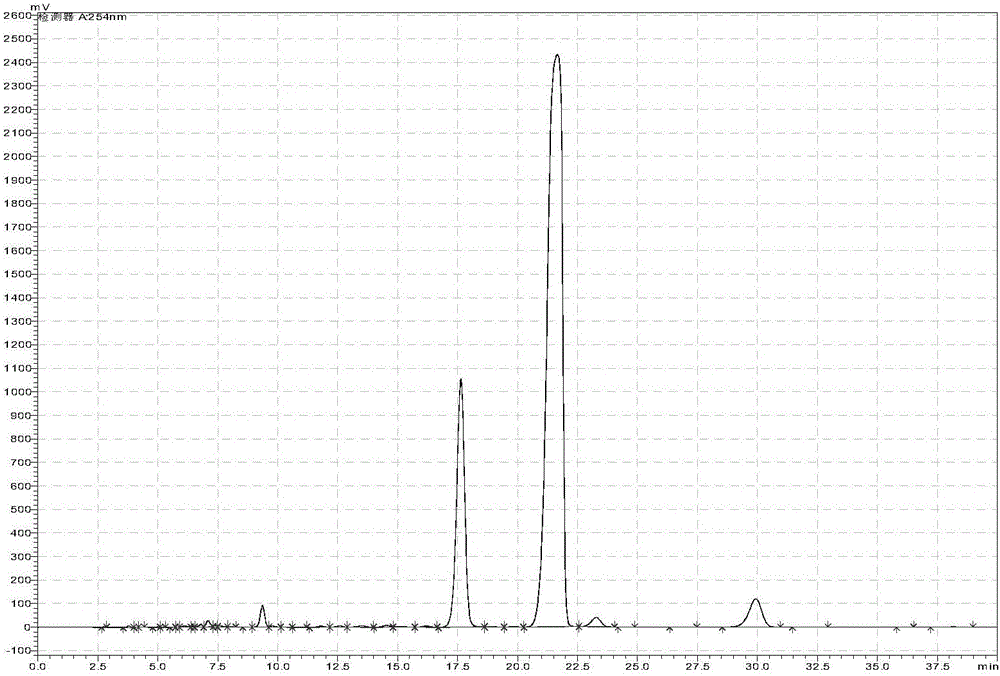

[0030] Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.05MPa, 120°C for 1.5h, then put it in an oven at 120°C, and cool it down to 15°C after 2h, when a large amount of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 70°C. The obtained crystals were placed in a Buchner funnel with filter paper, and pseudocumene was added dropwise at -0.05 MPa until the needle crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

Embodiment 3

[0032]Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.03MPa, 130°C for 4.5h, put it in an oven at 130°C, and cool it down to 15°C after 3h, when a large amount of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 55°C. The obtained crystals were placed in a Buchner funnel with filter paper, and 1,3,5-trimethylbenzene was added dropwise at -0.03 MPa until the needle-like crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com