Antimicrobial packaging film with intelligent controlled-release performance, and preparation method and application thereof

A technology of intelligent controlled release and packaging film, applied in application, food preservation, food science, etc., can solve the problems of inactivation of antibacterial agents, decline of physical and mechanical properties, and prone to violent release, so as to ensure safety and quality and solve related problems. Capacitance problem, the effect of solving high temperature deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

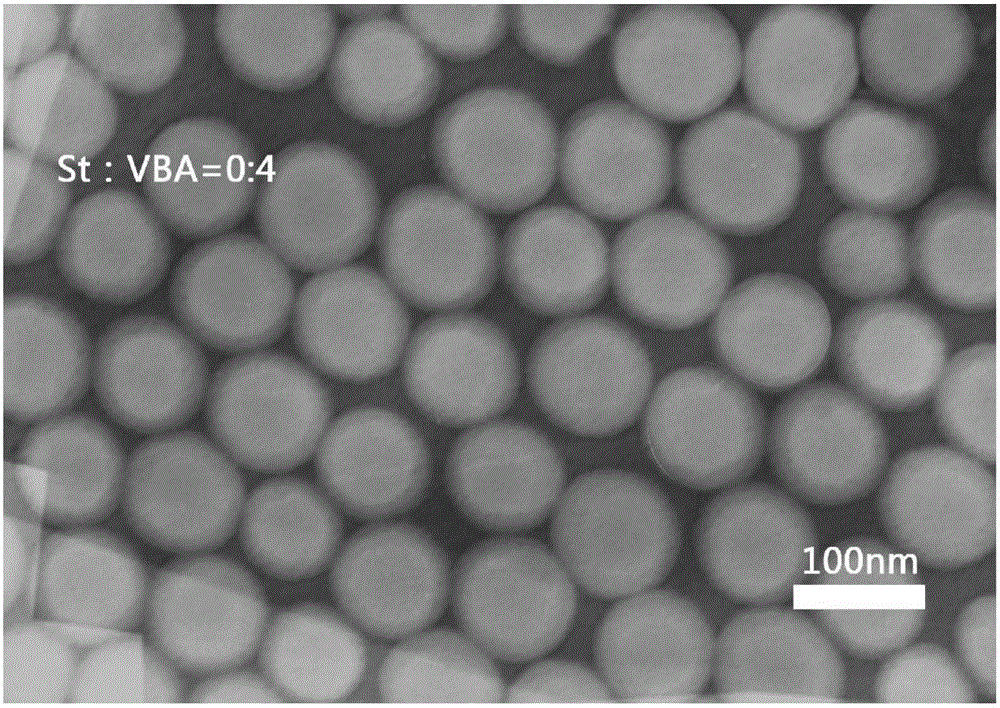

[0054] The aldehyde-containing nanospheres with core-shell structure with adjustable particle size provided in this example have a particle diameter of 173 nm and a dispersion of 0.2. The core monomer of the aldehyde-containing nanospheres It is styrene, and the shell monomer is 4-vinylbenzaldehyde VBA, wherein the mass ratio of the core monomer and the shell monomer is 4:1.

[0055] The preparation method of the aldehyde-containing nano-microspheres with a core-shell structure with adjustable particle size is as follows:

[0056] (1) Screening and preparation of emulsifiers and initiators

[0057] Among the amphoteric emulsifiers, DNS-86, DNS-268 and DNS-458 are commonly used, but when the former two are used for polymerization, the obtained microspheres are unstable and easy to aggregate, which may be caused by incomplete emulsification. In view of this , choose DNS-458 (purchased from Guangzhou Double Bond Trading Co., Ltd., here is only for enumeration, without limitation...

Embodiment 2

[0069] The aldehyde-containing nanospheres with a core-shell structure with adjustable particle size provided in this example have a particle diameter of about 300 nm and a dispersion of 0.202. The core sheet of the aldehyde-containing nanospheres The body is styrene, and the shell monomer is 4-vinylbenzaldehyde VBA and styrene St, wherein the mass ratio of the core monomer and the shell monomer is 4:1, and the 4-vinylbenzaldehyde VBA in the shell monomer The mass ratio of styrene St is 1:3.

[0070] The preparation method of the aldehyde-containing nano-microspheres with core-shell structure with adjustable particle size is different from Example 1 in that:

[0071] The amount of the cross-linking monomer is 0.5% of the total mass of the core monomer and the shell monomer.

[0072] The consumption of emulsifier is 5% of the total mass of core monomer and shell monomer, wherein in the core emulsion, the consumption of cross-linking monomer is 82% of the total mass of cross-li...

Embodiment 3

[0080] The aldehyde-containing nanospheres with a core-shell structure with adjustable particle size provided in this example have a particle diameter of about 120 nm and a dispersion of 0.15. The core sheet of the aldehyde-containing nanospheres The body is styrene, and the shell monomer is 4-vinylbenzaldehyde VBA and styrene St, wherein the mass ratio of the core monomer and the shell monomer is 4:1, and the 4-vinylbenzaldehyde VBA in the shell monomer The ratio of mass parts to styrene St is 3:1.

[0081] The preparation method of the aldehyde-containing nano-microspheres with core-shell structure with adjustable particle size is different from Example 1 in that:

[0082] The amount of the cross-linking monomer is 1.5% of the total mass of the core monomer and the shell monomer.

[0083] The consumption of emulsifier is 3% of the total mass of core monomer and shell monomer; Wherein in core emulsion, the consumption of cross-linking monomer is 78% of the total mass of cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com