Piston type SMA-piezoelectric composite variable friction damper

A piezoelectric composite and variable friction technology, which is applied in the direction of protective buildings/shelters, building components, building types, etc., can solve the problems of inability to consume energy and shock absorption, no self-resetting ability, poor energy consumption, etc. problem, to achieve the effect of large driving force, meeting the needs of energy dissipation and vibration reduction, and good self-resetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

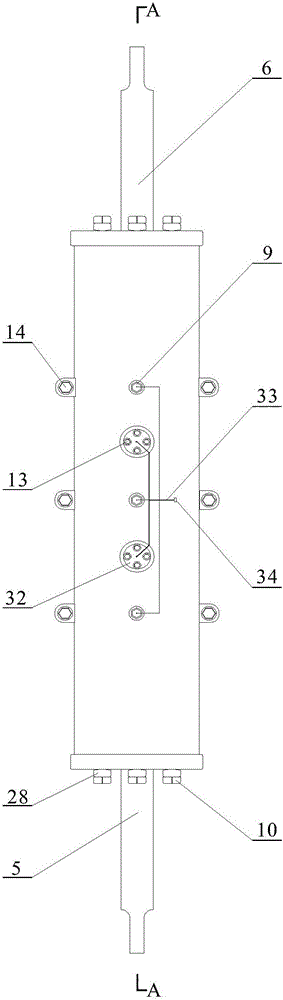

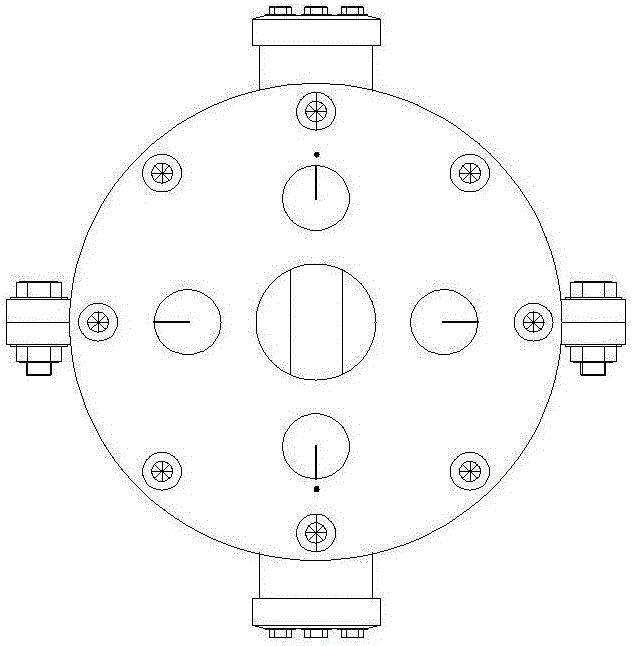

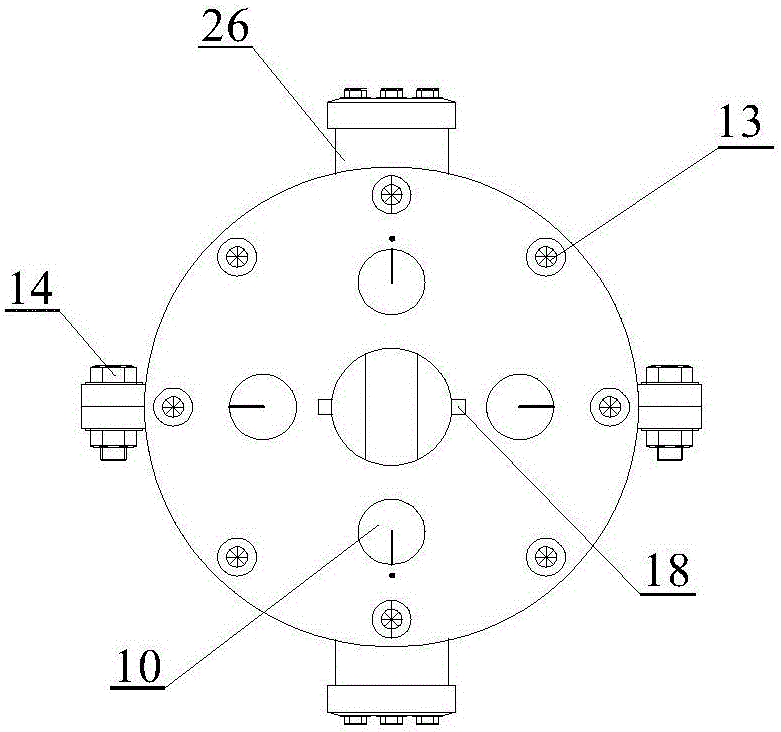

[0022] exist Figure 1 to Figure 13In the schematic diagram of the present invention shown, the outer cylinder 1 is a hollow cylinder with upper and lower openings, and the outer cylinder is divided into two parts, which are tightly connected up and down by connecting bolts 14. At the upper and lower ends of the outer cylinder, respectively Link to each other with upper cylinder cover 2, lower cylinder cover 17 by grub screw 13, the structure of upper cylinder cover and lower cylinder cover is identical. The upper cylinder cover is a circular flat plate, and screw through holes are evenly distributed along the periphery of the upper cylinder cover, and flat head screws are inserted into the through holes. A circumferential threaded hole is arranged on the upper cylinder head and the lower cylinder head, and an adjusting bolt 28 is inserted in the threaded hole, and the adjusting bolt and the adjusting nut 10 are engaged with each other. The middle parts of the upper cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com