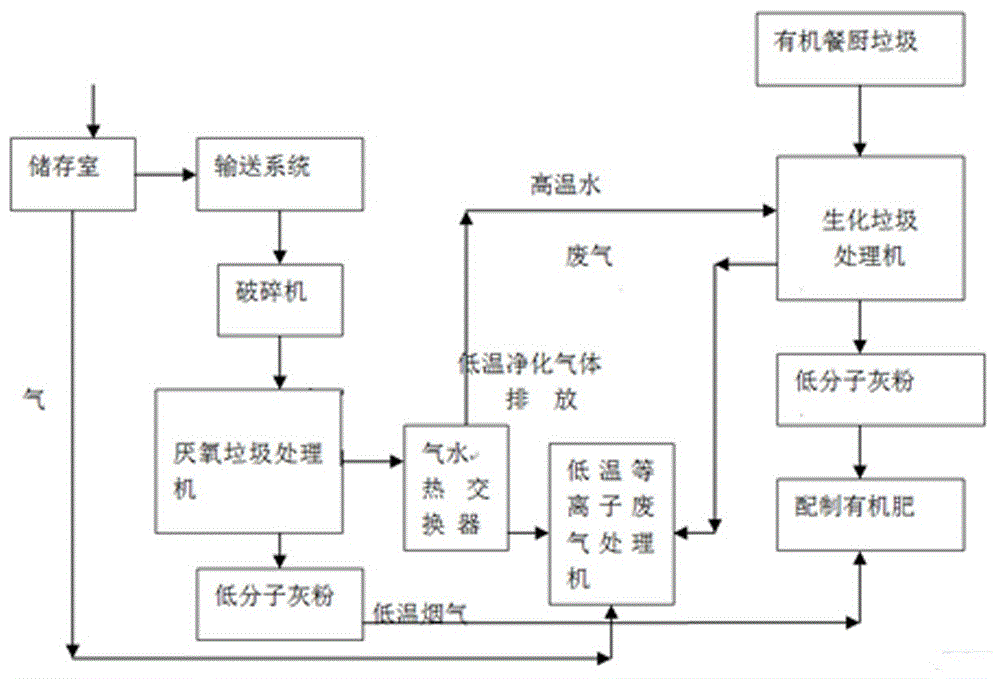

Anaerobic rubbish decomposition technology

A technology of waste and cracking furnace, applied in lighting and heating equipment, combustion method, combustion type, etc., can solve the problem of inability to decompose and treat, and achieve the effect of significant waste reduction, reduced operating cost, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

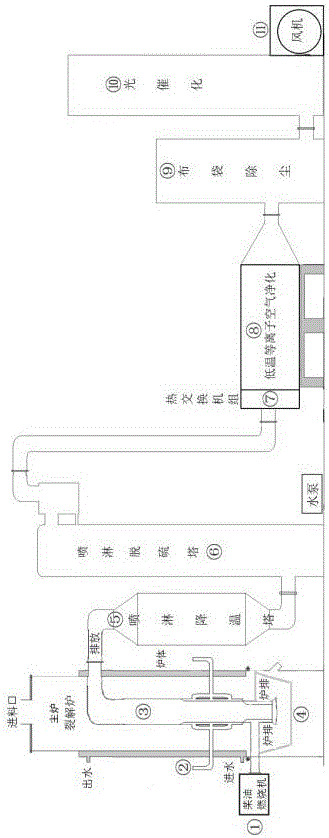

[0018] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: anaerobic waste decomposition device, including diesel burner 1, air distribution pipe 2 of second combustion chamber, second combustion chamber 3, vertical grate 4, spray cooling tower 5, desulfurization and dust removal tower 6. Heat exchange equipment 7, low-temperature plasma air purifier 8, bag dust removal equipment 9, photocatalyst 10, fan 11 and water pump 12, diesel burner 1 is connected to the main furnace cracking furnace, and the main furnace cracking furnace is equipped with secondary combustion Chamber 3, vertical fire grate 4, the second combustion chamber 3 is connected with the spray cooling tower 5, the two sides of the second combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com