Illuminating film structure

A lighting film and film structure technology, applied in lighting devices, lighting and heating equipment, printed circuits, etc., can solve problems such as the limitation of lighting surface flexibility, and achieve the effect of flexibility and thickness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments are merely examples. Although this specification may refer to "one" embodiment in several places, this does not necessarily mean that each such reference is to the same embodiment(s) or that a feature is only applicable to a single embodiment. Single features of different embodiments may also be combined to provide other embodiments. Furthermore, the words "comprising" and "comprising" should not be understood as limiting the described embodiments to consist of only those features that have been mentioned, and such embodiments may also contain features / structures that have not been specifically mentioned.

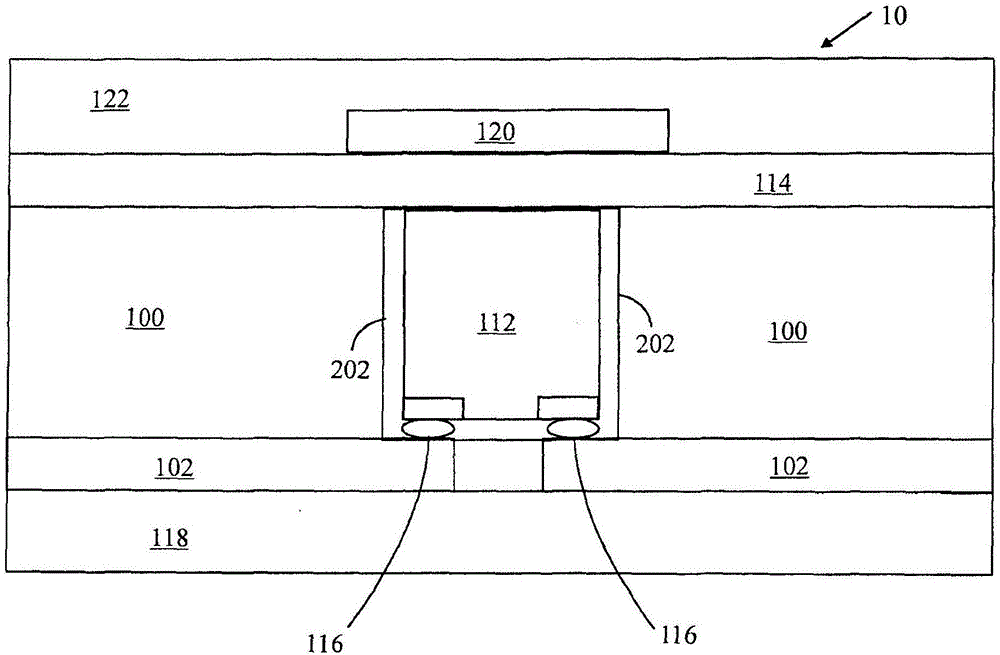

[0021] It should be noted that while the figures illustrate various embodiments, they are simplified and only show some structural and / or functional entities. Connections shown in the figures may refer to electrical and / or physical connections. It will be clear to those skilled in the art that the described devices may also include other f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com