A kind of inorganic cementitious material and preparation method thereof

An inorganic cementitious material and cementitious material technology, applied in the field of building materials, can solve the problems of less fly ash consumption, high fly ash quality requirements, poor product performance, etc., to achieve less greenhouse gas emissions and improve production. Benefit and equipment use efficiency, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

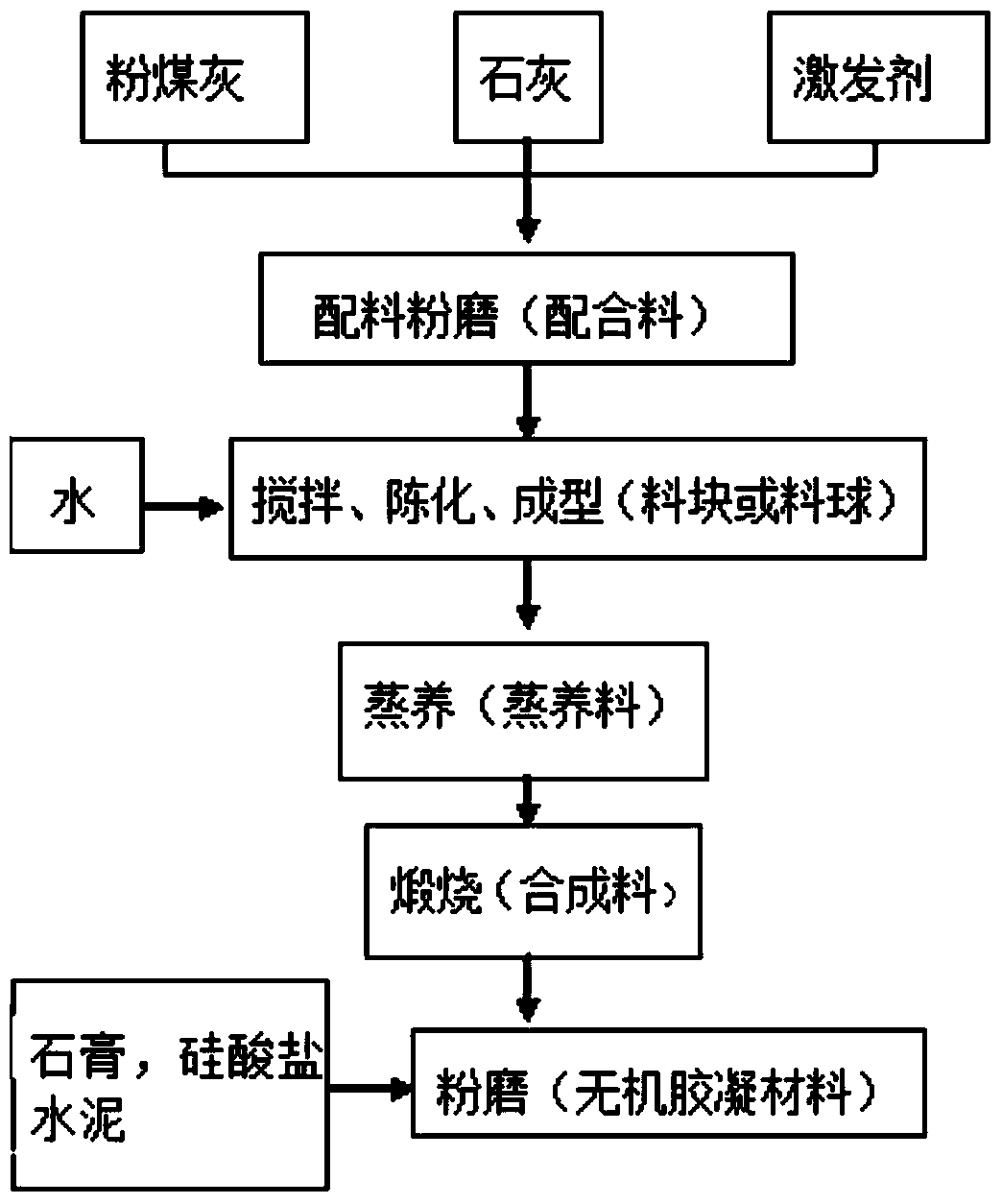

Method used

Image

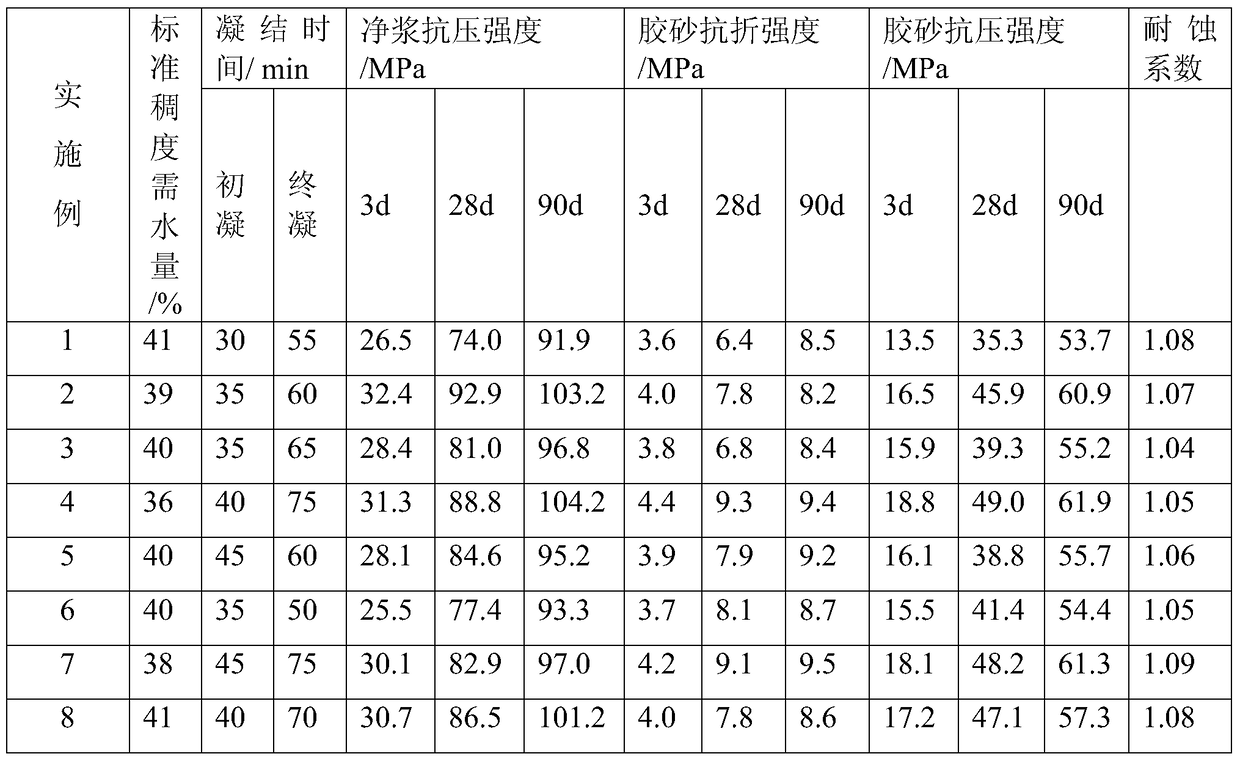

Examples

Embodiment 1

[0025] The batch contains the following ingredients in parts by mass:

[0026] 80 parts of fly ash

[0027] Quicklime calculated as CaO 20 parts

[0028] Sodium hydroxide 0.5 parts

[0029] Weigh fly ash, quicklime, and sodium hydroxide according to the above mass ratio, and grind them together until the fineness is 45 μm and the sieve residue is 5.2% of the batching material; pour the batching material into the mixer, add 35 parts of water, stir for 3 minutes, and age After melting for 2 hours, use a ball forming disc to form pellets with a diameter of 8 to 16mm; steam the pellets in a steam curing box at 90°C for 10 hours to obtain steamed feed, and use a small kiln to calcinate the steamed feed at 750°C for 90 minutes and then blow it to cool. Synthetic material: Take 70 parts of synthetic material, 20 parts of Portland cement and 10 parts of anhydrite and grind together until the specific surface area is 350m 2 / kg to prepare a fast-setting high-strength inorganic gelli...

Embodiment 2

[0031] The batch contains the following ingredients in parts by mass:

[0032] 70 parts of fly ash

[0033] Quicklime calculated as CaO 30 parts

[0034] Sodium hydroxide 1.0 parts

[0035] Weigh fly ash, quicklime, and sodium hydroxide according to the above mass ratio, and grind them together until the fineness is 45 μm and the sieve residue is 5.8% of the batching material; pour the batching material into the mixer, add 45 parts of water, stir for 2 minutes, and age After melting for 2.5 hours, use a ball forming disc to form pellets with a diameter of 8-16mm; steam the pellets in a steam curing box at 95°C for 8 hours to obtain steamed feed, and then calcine the steamed feed in a small kiln at 800°C for 60 minutes and then blow it to cool Obtain synthetic material; take 68 parts of synthetic material, 25 parts of Portland cement and 7 parts of dihydrate gypsum to grind together until the specific surface area is 415m 2 / kg to prepare a fast-setting high-strength inorgan...

Embodiment 3

[0037] The batch contains the following ingredients in parts by mass:

[0038] 75 parts of fly ash

[0039] Quicklime calculated as CaO 25 parts

[0040] Sodium carbonate 1.4 parts

[0041] Weigh fly ash, quicklime, and sodium carbonate according to the above mass ratio, and grind them together until the fineness is 45 μm, and the sieve residue is 9.8%; pour the batch into the mixer, add 40 parts of water, stir for 3 minutes, and age After 3 hours, it is extruded into a material block of 240mm×115mm×53mm, and the material block is steamed in a steam curing box at 90°C for 16 hours to obtain the steamed nutrient, and the steamed nutrient is calcined in a small kiln at 750°C for 75 minutes, and then naturally cooled in the air to synthesize Materials; use a crusher to break the synthetic material into particles smaller than 16mm, take 67 parts of synthetic material, 25 parts of Portland cement and 8 parts of hemihydrate gypsum and grind together until the specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com