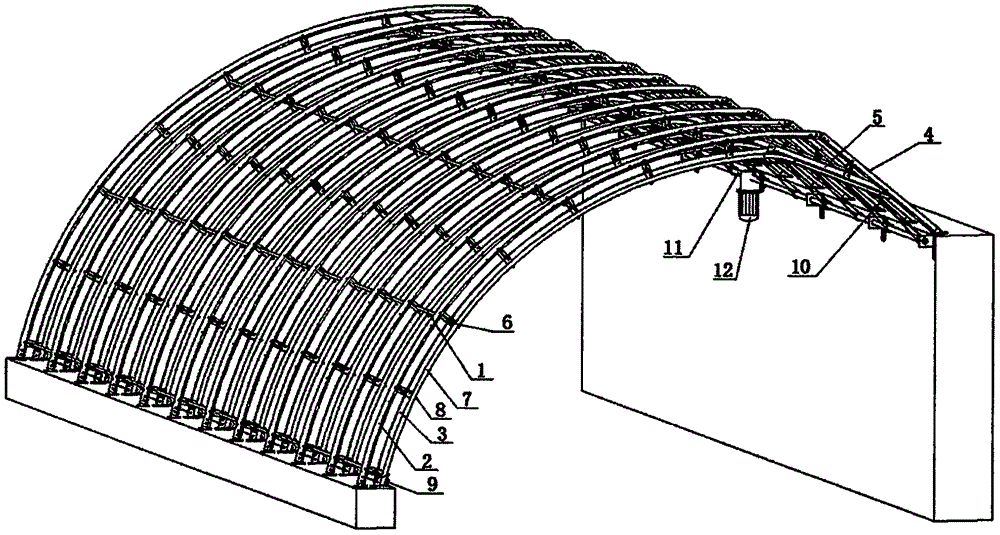

Assembled double-chord beam greenhouse skeleton

A greenhouse and assembled technology, which is applied in the field of assembled double string beam greenhouse framework, can solve the problems of high labor cost, inconvenient operation, and decreased light transmittance of the greenhouse film, so as to achieve stable and reliable operation, improve heat preservation effect, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

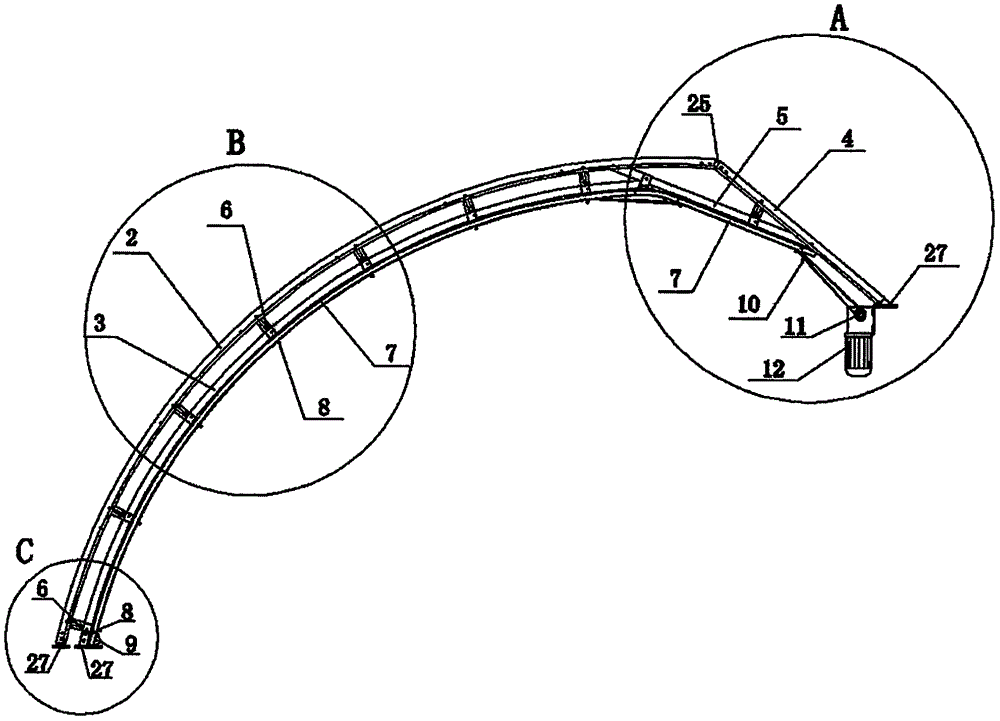

[0038] Example 1: as Figure 1 to Figure 11As shown, an assembled double-chord greenhouse frame, which includes twelve double-chord beams and four cross bars 1; Beam 5, the upper end of the upper chord beam 2 is connected with the upper end of the rear slope main beam 4, the oblique beam 5 is connected between the upper chord beam 2 and the rear slope main beam 4 to form a triangular support structure, the upper end of the lower chord beam 3 is connected with the oblique beam 5, the upper chord Seven cross connecting pieces 6 are connected between the beam 2 and the lower chord beam 3, and the four cross bars 1 connect twelve double chord beams together through the cross connecting pieces 6; Structure, the lower chord 3 and the oblique beam 5 are made of square tubes; the lower side of the lower chord 3 and the oblique beam 5 is provided with a slide rail 7, a number of curtain pulleys 8 are provided in the slide rail 7, and the lower end of the slide rail 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com