A method for coupling MBR/MFC with PVDF/carbon fiber-based MFE2O4 type photocatalytic conductive filter membrane

A photocatalysis and carbon fiber technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as high energy consumption and membrane pollution, and achieve the effect of improving sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.90g FeCl 3 ·6H 2 O and 0.40 g CoCl 2 ·6H 2 O, add 50mL of ethylene glycol and 20mL of 5mol / L NaOH solution in sequence, stir evenly and ultrasonicate for 5min, then pour the solution into a glass dish dedicated to microwave, and heat it with microwave until the solvent is completely evaporated to obtain CoFe 2 o 4 nanoparticles. The combined product has magnetic characteristics, and the product is washed with deionized water to remove ionic impurities, and then suction-filtered with an aqueous phase filter membrane. The resulting solid is placed in a vacuum oven for drying to obtain pure CoFe 2 o 4 nanoparticles.

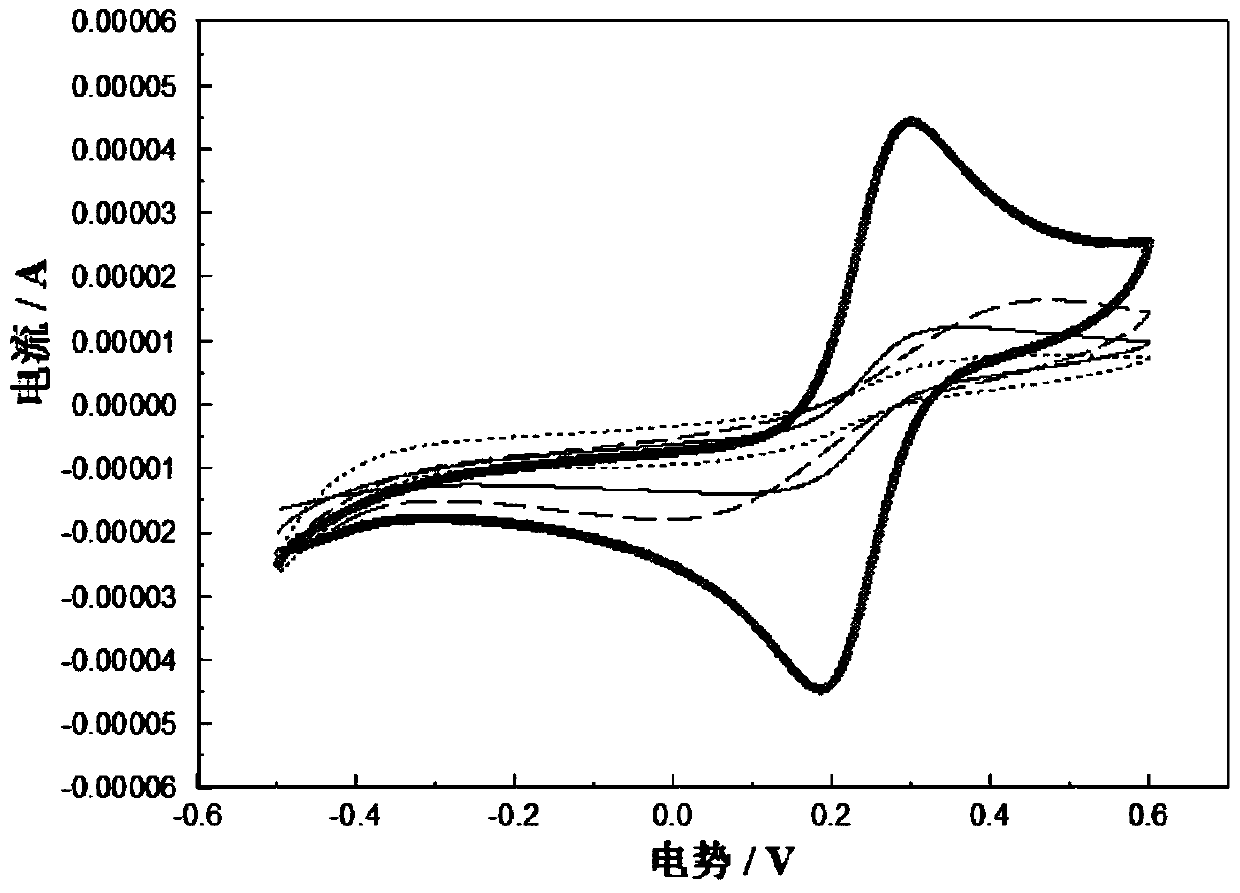

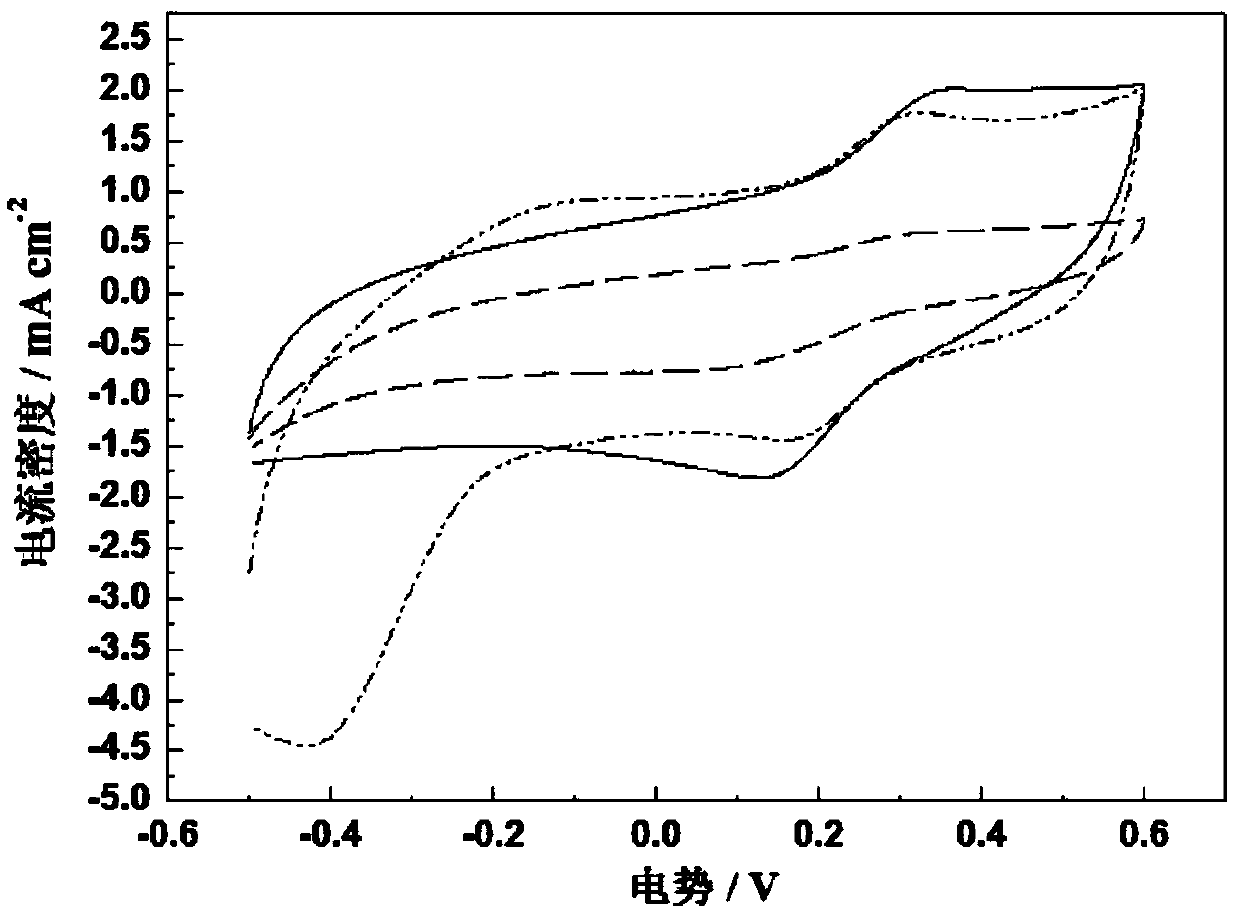

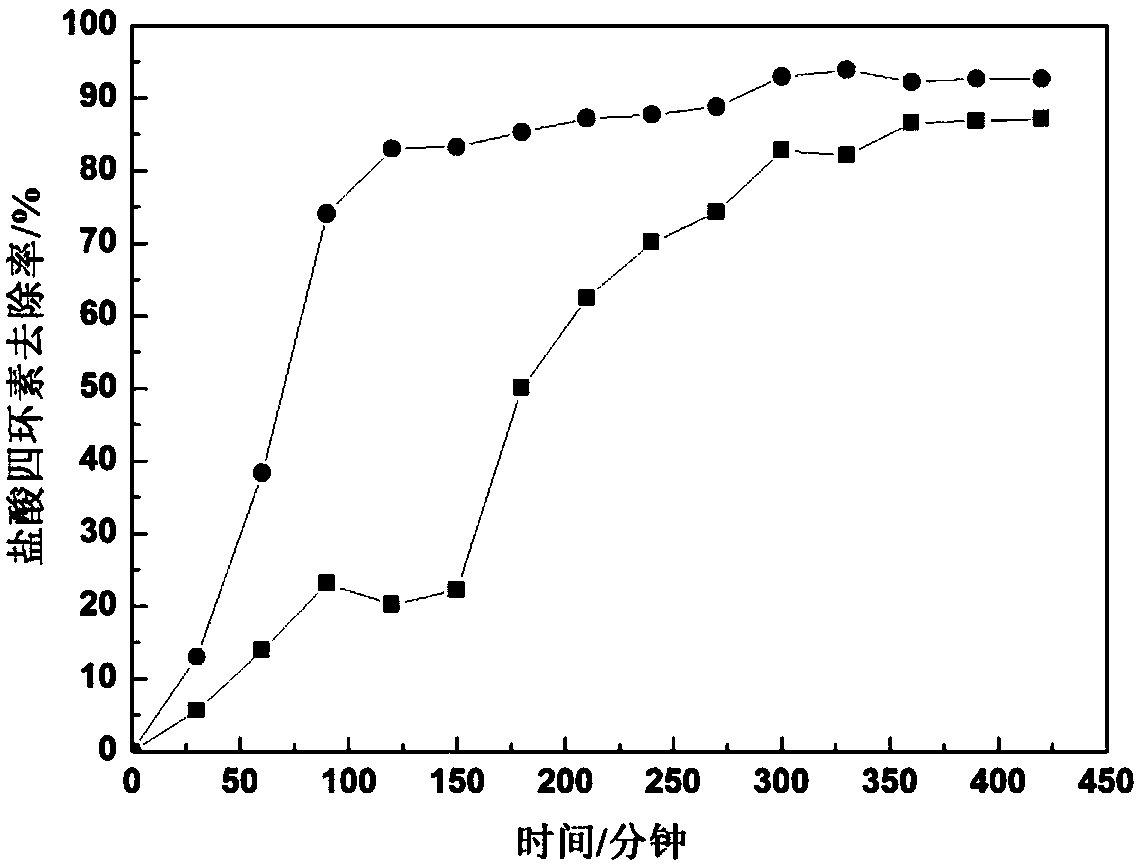

[0026] Add 0.2g of carbon powder to the 5% PVDF casting solution, stir well, then add 0.1g of CoFe 2 o 4 , after stirring evenly, let it defoam and stand still, lay a piece of carbon fiber cloth (thickness is about 250 μm) on a flat glass plate, coat a 200 μm PVDF membrane on its surface, immerse in deionized water for phase inversion overnig...

Embodiment 2

[0029] Weigh 0.90g FeCl 3 ·6H 2 O and 0.23 g CoCl 2 ·6H 2 O, add 100mL of ethylene glycol and 5mL of 13mol / L NaOH solution in turn, stir evenly and ultrasonically for 20min, then pour the solution into a glass dish, heat with microwave until the solvent evaporates completely, and obtain CoFe 2 o 4 nanoparticles. The combined product has magnetic characteristics, and the product is washed with deionized water to remove ionic impurities, and then suction-filtered with an aqueous phase filter membrane. The resulting solid is placed in a vacuum oven for drying to obtain pure CoFe 2 o 4 nanoparticles.

[0030]In the 16% PVDF casting solution, add 2g of carbon powder, stir evenly, and then add 2g of CoFe 2 o 4 , after stirring evenly, defoaming and standing still, lay a piece of carbon fiber cloth (thickness about 250 μm) on a flat glass plate, coat a 2000 μm PVDF membrane on its surface, immerse in deionized water for phase inversion overnight, and obtain PVDF / carbon fibe...

Embodiment 3

[0033] Weigh 0.90g FeCl 3 ·6H 2 O and 0.48 g CoCl 2 ·6H 2 O, add 80mL of ethylene glycol and 8mL of 7.5mol / L NaOH solution in turn, stir evenly, place in an ultrasonic cell pulverizer for 15 minutes of ultrasonication, then pour the solution into a microwave-specific glass dish, and heat with microwave until the solvent is completely evaporated to obtain CoFe 2 o 4 nanoparticles. The combined product has magnetic characteristics, and the product is washed with deionized water to remove ionic impurities, and then suction-filtered with an aqueous phase filter membrane. The resulting solid is placed in a vacuum oven for drying to obtain pure CoFe 2 o 4 nanoparticles.

[0034] In 10% PVDF casting solution, add 0.3g carbon powder, stir evenly, then add 0.1-0.3g CoFe 2 o 4 , after stirring evenly, defoaming and standing still, lay a carbon fiber cloth (thickness about 250 μm) on a flat glass plate, coat a 300 μm PVDF membrane on its surface, immerse in deionized water for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com