Method for handling livestock died of epidemic disease

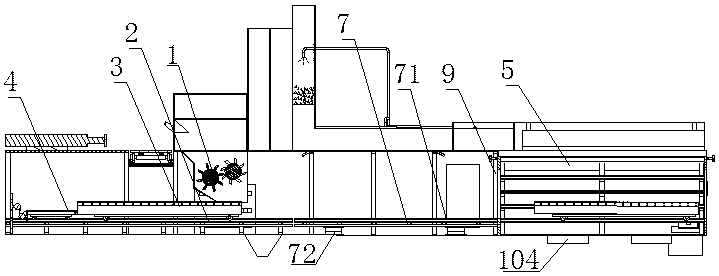

A technology for the treatment of sick and dead livestock and poultry, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of high investment and treatment costs for harmless treatment, low resource utilization value, diseased poultry problems such as the inflow of livestock into the market, to achieve the effect of solving high sewage treatment volume, high degree of resource utilization, and good growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

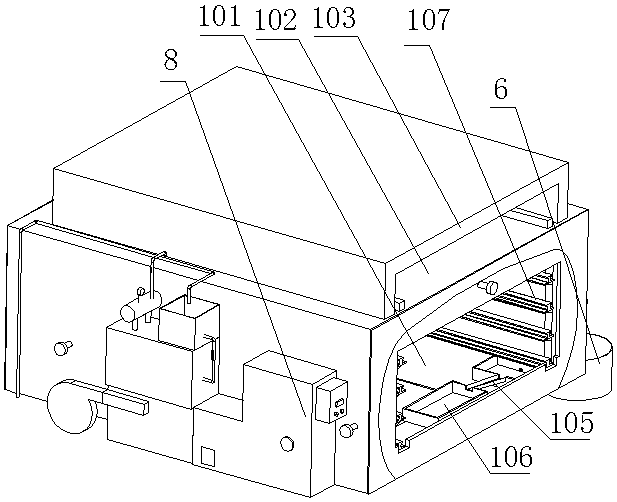

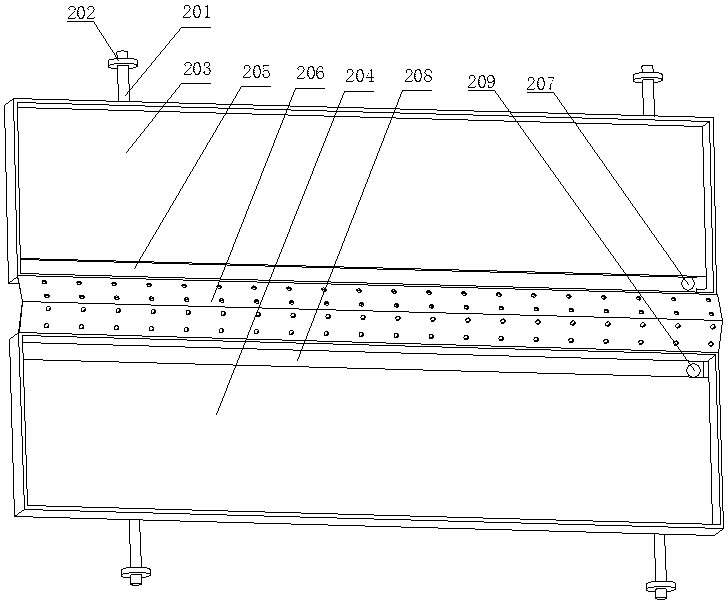

[0028] The collected dead livestock and poultry are disintegrated with a disintegration device; the disintegrated corpses are put into the debris receiving device; the disintegrated corpses are put into the drying room with a temperature of 120 The hot gas at ℃ is directly sterilized and dried, and the oil flowing out during the sterilizing and drying process flows into the oil collection tank; the sterilized and dried meat, hair and bones are pressed; after pressing, the oil and remaining materials are obtained. After the remaining material is pulverized, add the mixed material to make the feeding raw material; in the feeding raw material, the absolute dry mass ratio of the remaining material obtained after pressing and the mixed material is 1:1, and the mixed material is 20 parts by mass of kitchen waste, pulverized A mixture of 45 parts by mass of straw, 30 parts by mass of pig manure or / and poultry manure, and 2 parts by mass of lime; 3 parts by mass of EM with a pH value o...

Embodiment 2

[0030] The collected dead livestock and poultry are disintegrated with a disintegration device; the disintegrated corpses are put into the debris receiving device; the disintegrated corpses are placed in the drying room with a temperature of 320 The hot gas at ℃ is directly sterilized and dried, and the oil flowing out during the sterilizing and drying process flows into the oil collection tank; the sterilized and dried meat, hair and bones are pressed; after pressing, the oil and remaining materials are obtained. After the remaining material is pulverized, add the mixed material to make the feeding raw material; in the feeding raw material, the absolute dry mass ratio of the remaining material obtained after pressing and the mixed material is 1:10, and the mixed material is 40 parts by mass of kitchen waste, crushed A mixture of 30 parts by mass of straw, 20 parts by mass of pig manure or / and poultry manure, and 1 part by mass of lime; 1 part by mass of EM with a pH value of 5...

Embodiment 3

[0032] The collected dead livestock and poultry are disintegrated with a disintegration device; the disintegrated corpses are put into the debris receiving device; the disintegrated corpses are put into the drying room with a temperature of 200 The hot gas at ℃ is directly sterilized and dried, and the oil flowing out during the sterilizing and drying process flows into the oil collection tank; the sterilized and dried meat, hair and bones are pressed; after pressing, the oil and remaining materials are obtained. After the remaining material is pulverized, add the mixed material to make the feeding raw material; in the feeding raw material, the absolute dry mass ratio of the remaining material obtained after pressing and the mixed material is 1:5, and the mixed material is 30 parts by mass of kitchen waste, pulverized A mixture of 38 parts by mass of straw, 25 parts by mass of pig manure or / and poultry manure, and 1.5 parts by mass of lime; 5 parts by mass of EM with a pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com